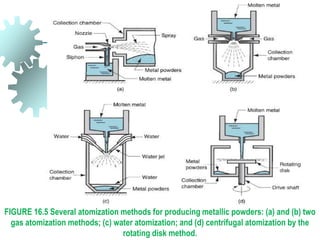

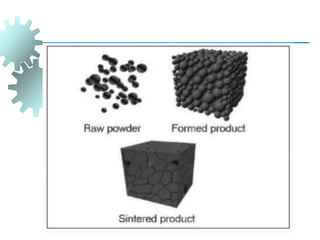

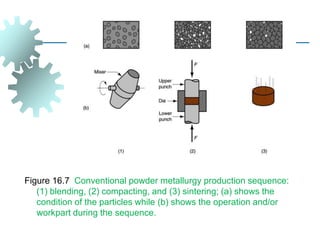

The document outlines the stages of powder metallurgy (PM) production, which include preparing raw materials, blending, compaction, and sintering. It details methods for producing metallic powders and discusses limitations of PM technology, such as high costs and geometry constraints. Additionally, the document addresses processes like impregnation and infiltration, as well as alternative processing methods for PM parts.