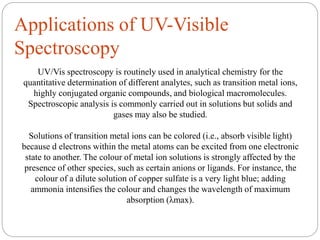

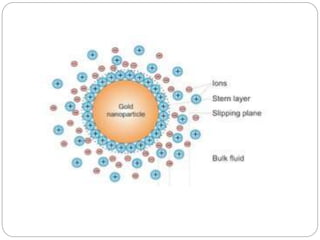

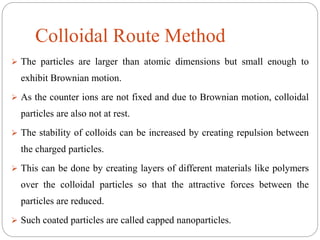

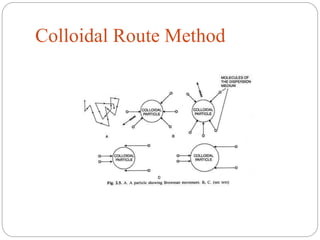

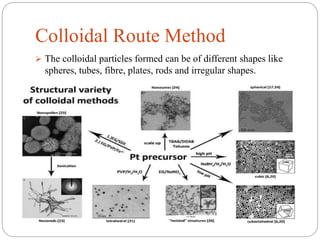

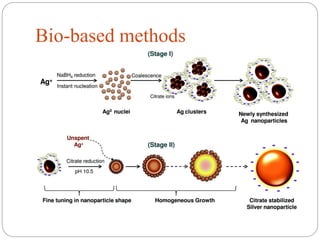

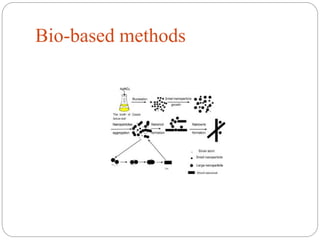

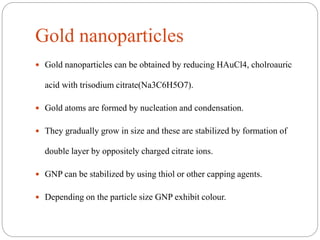

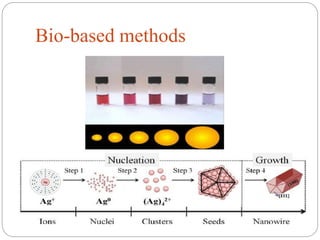

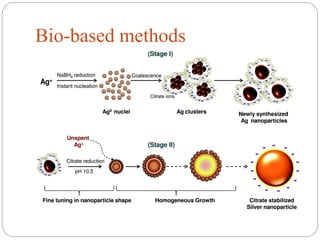

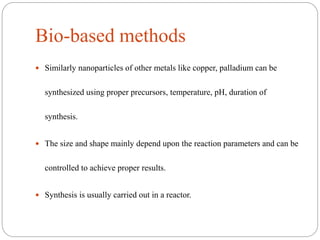

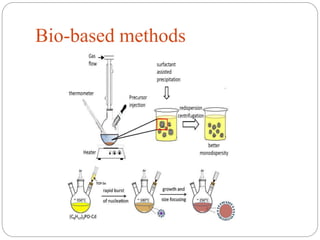

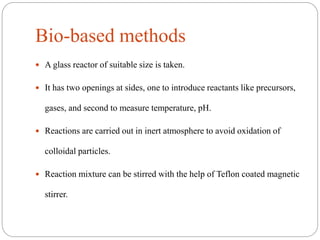

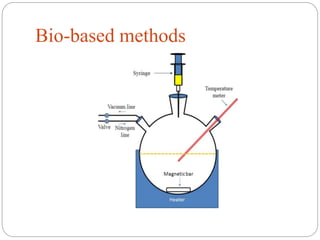

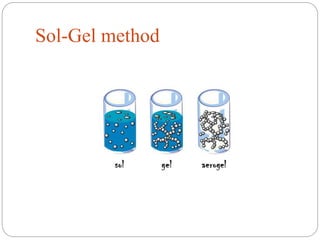

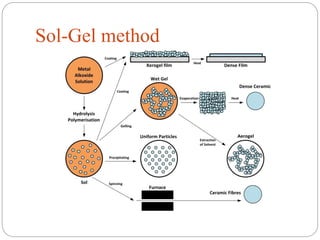

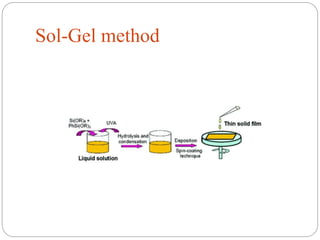

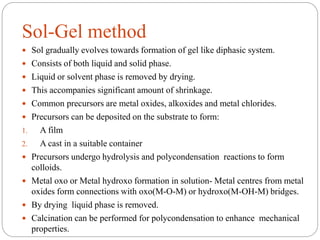

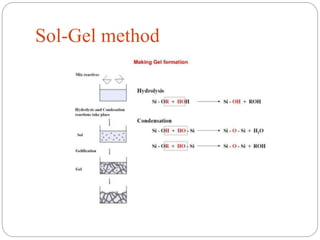

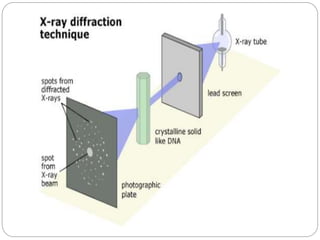

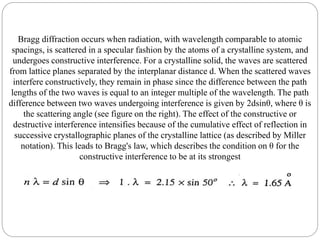

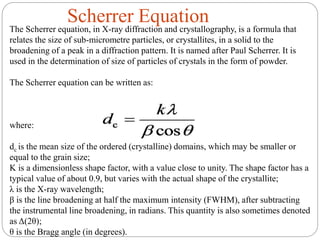

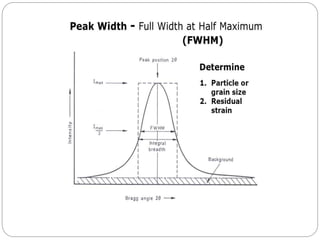

The document discusses nanomaterials, defined as particles ranging from 1nm to 100nm, and outlines various synthesis methods including physical, chemical, biological, and hybrid approaches. Key techniques, particularly chemical methods, include the colloidal route and sol-gel method, emphasizing their advantages in producing nanoparticles of different shapes and sizes. Additionally, the document highlights the characterization of nanomaterials using techniques like X-ray diffraction and UV-visible spectroscopy, which reveal unique properties at the nanoscale essential for various applications.

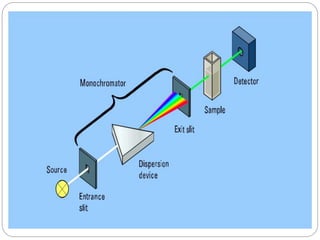

![UV -Visible Spectroscopy

Ultraviolet–visible spectroscopy or ultraviolet-visible spectrophotometry (UV-Vis

or UV/Vis) refers to absorption spectroscopy or reflectance spectroscopy in the

ultraviolet-visible spectral region. This means it uses light in the visible and

adjacent (near-UV and near-infrared [NIR]) ranges. The absorption or reflectance

in the visible range directly affects the perceived color of the chemicals involved.

In this region of the electromagnetic spectrum, atoms and molecules undergo

electronic transitions. Absorption spectroscopy is complementary to fluorescence

spectroscopy, in that fluorescence deals with transitions from the excited state to

the ground state, while absorption measures transitions from the ground state to

the excited state.](https://image.slidesharecdn.com/nanoppt-171031050730/85/Nanomaterials-48-320.jpg)