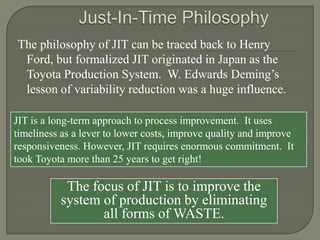

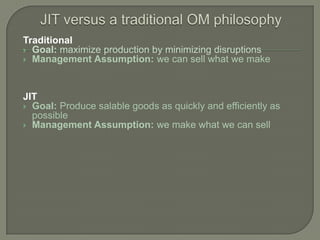

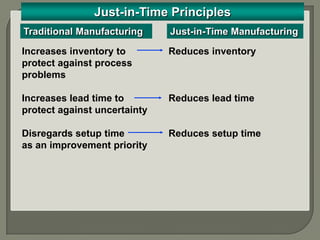

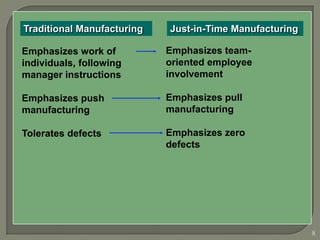

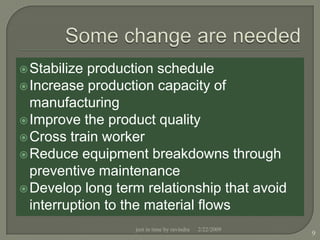

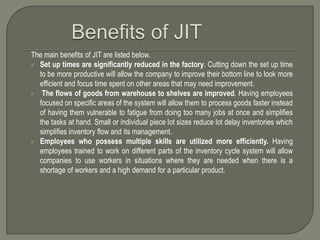

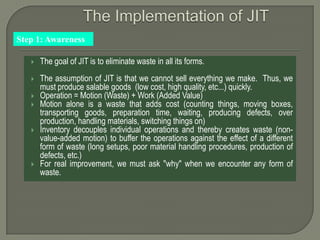

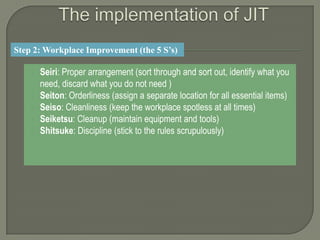

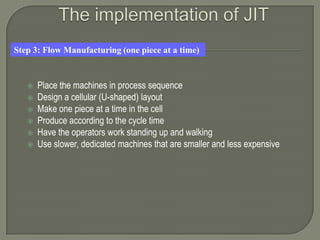

The document discusses just-in-time (JIT) manufacturing. It provides an introduction to JIT, outlines its key elements and benefits. Some of the main points covered include: eliminating waste is a core focus of JIT; it aims to produce goods as needed to eliminate excess inventory; setup time reduction is important; JIT requires long-term commitment and focuses on continuous improvement. The document also describes steps to implement JIT in manufacturing, such as workplace organization and flow-based production in cellular layouts.