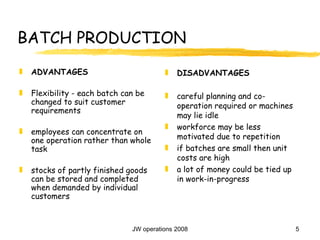

The document discusses different methods of production that businesses can use: job production, batch production, and flow production. It provides details on each method, including their typical applications, advantages, and disadvantages. Job production involves making a small number of unique units and is suitable for craft businesses. Batch production breaks production into batches and is used when demand is regular. Flow production organizes continuous operations to produce large quantities of standardized products. Businesses may combine methods, like using batch production for special products and flow for bottling.