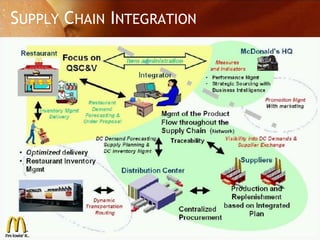

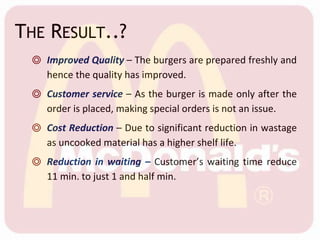

The document outlines the Just-In-Time (JIT) system implemented by McDonald's, which focuses on minimizing lead times and eliminating waste to enhance production efficiency. JIT allows McDonald's to prepare food only upon order, leading to improved quality, reduced wastage, and shorter customer wait times. Key benefits include lower inventory levels, enhanced product quality, and better labor utilization.