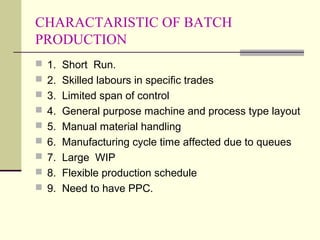

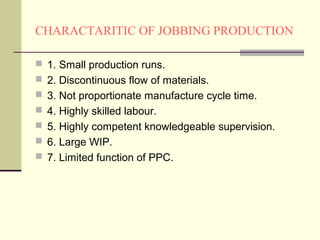

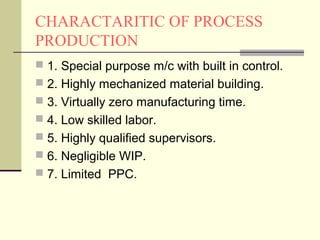

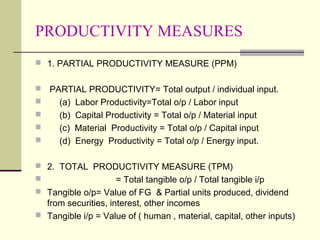

Production management encompasses planning and regulating the transformation of materials into finished products, guided by the 5 P's: products, plant, process, programs, and people. Its objectives include achieving the right quality, quantity, timing, and costs, while engaging in various activities at both strategic and operational levels, such as production planning and inventory control. Different production types (batch, mass, project, etc.) and productivity measures highlight the diverse approaches and metrics involved in maximizing efficiency and output in production systems.