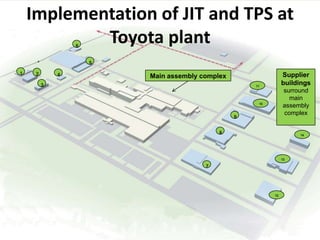

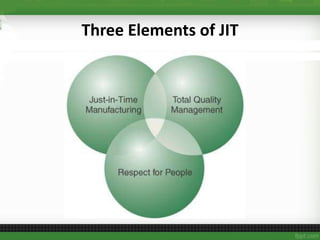

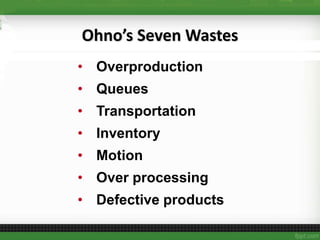

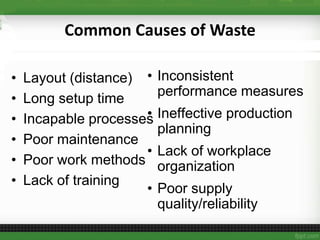

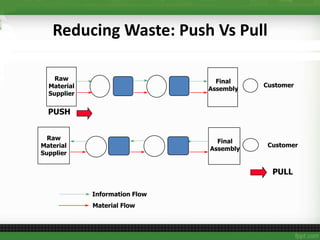

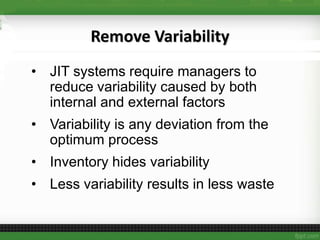

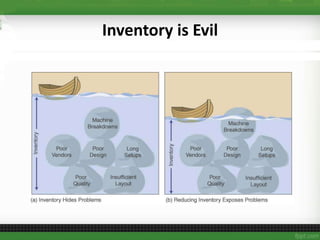

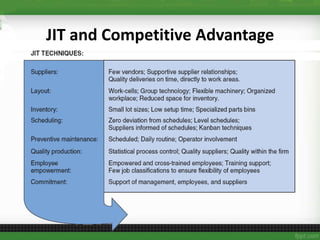

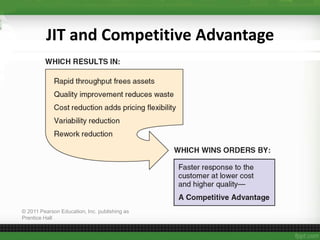

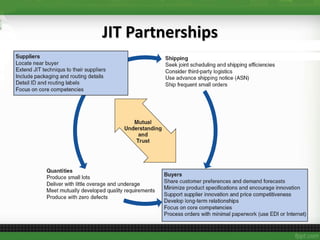

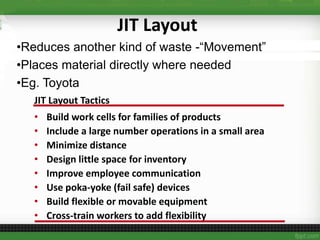

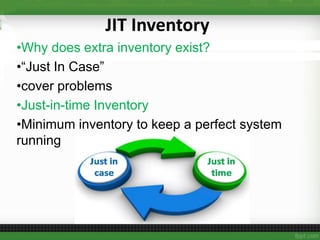

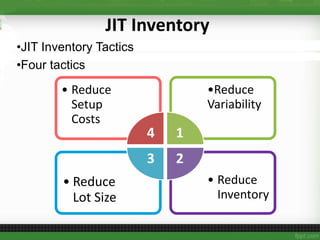

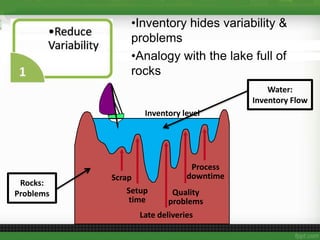

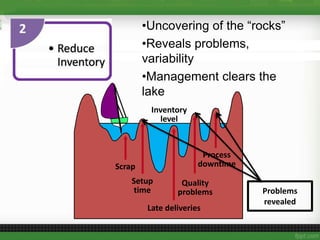

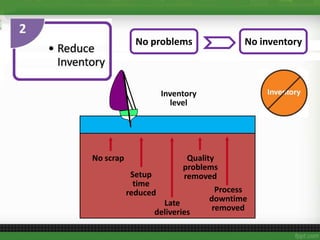

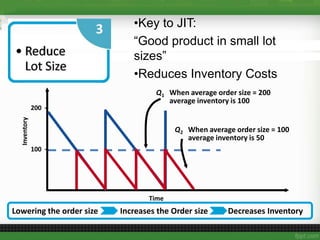

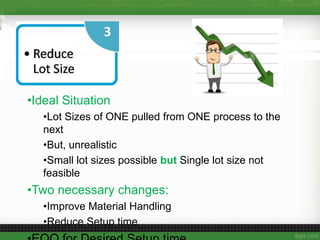

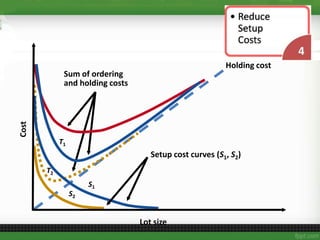

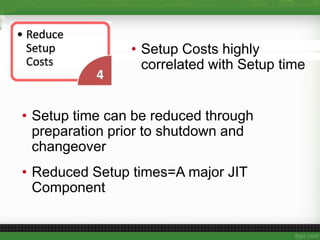

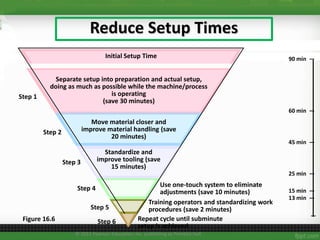

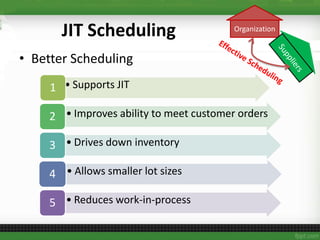

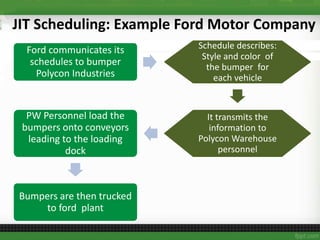

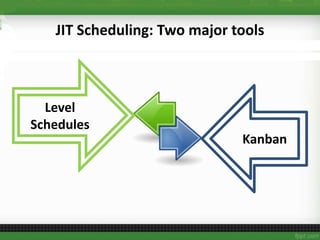

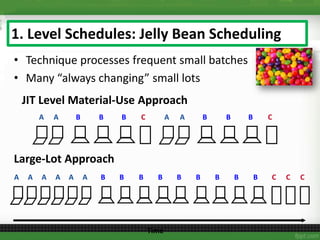

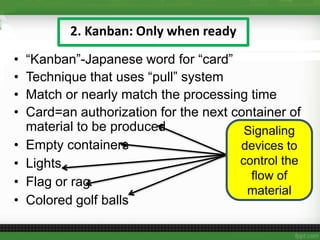

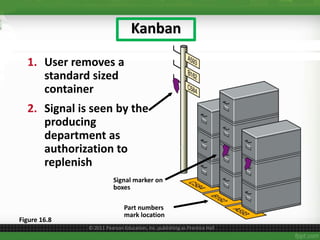

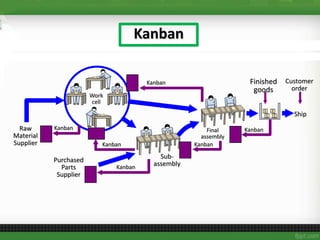

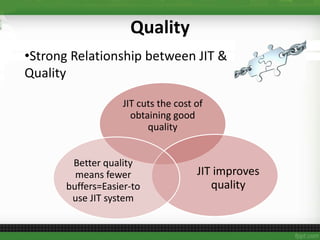

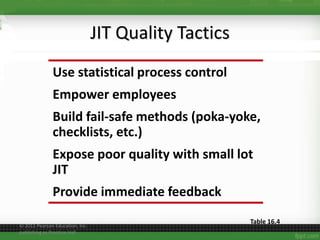

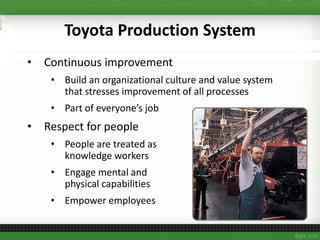

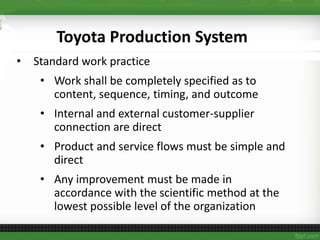

This document provides an overview of lean operations and just-in-time (JIT) manufacturing. It discusses that JIT aims to produce goods with minimum lead time and lowest cost by eliminating waste. Toyota popularized JIT techniques like reducing setup times and implementing kanban systems. Key aspects of JIT include eliminating waste, reducing variability, and improving throughput by pulling materials based on demand. JIT requires close supplier partnerships and scheduling to achieve small lot sizes and low inventories. The document outlines tactics to implement JIT principles in both manufacturing and service industries.