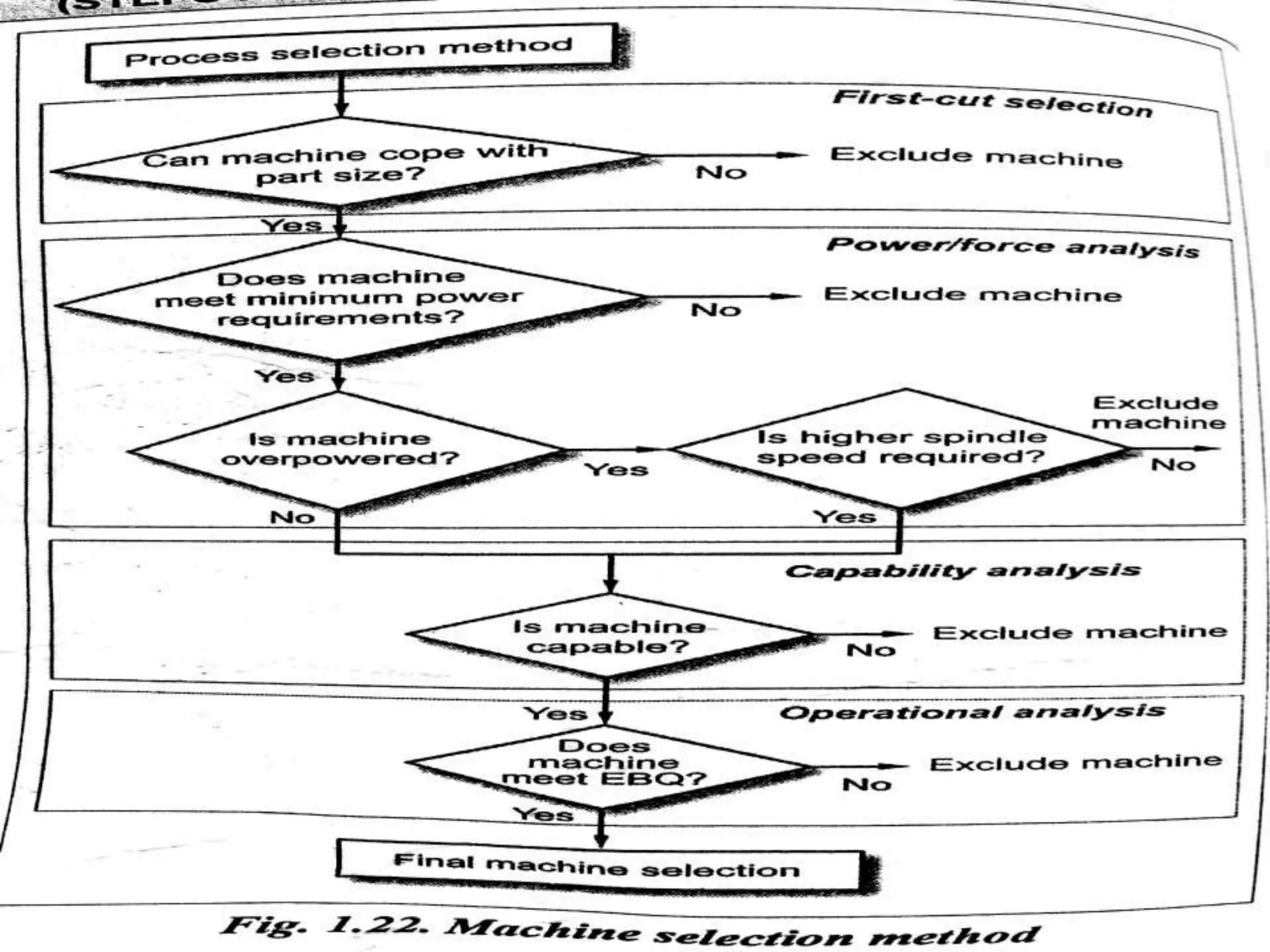

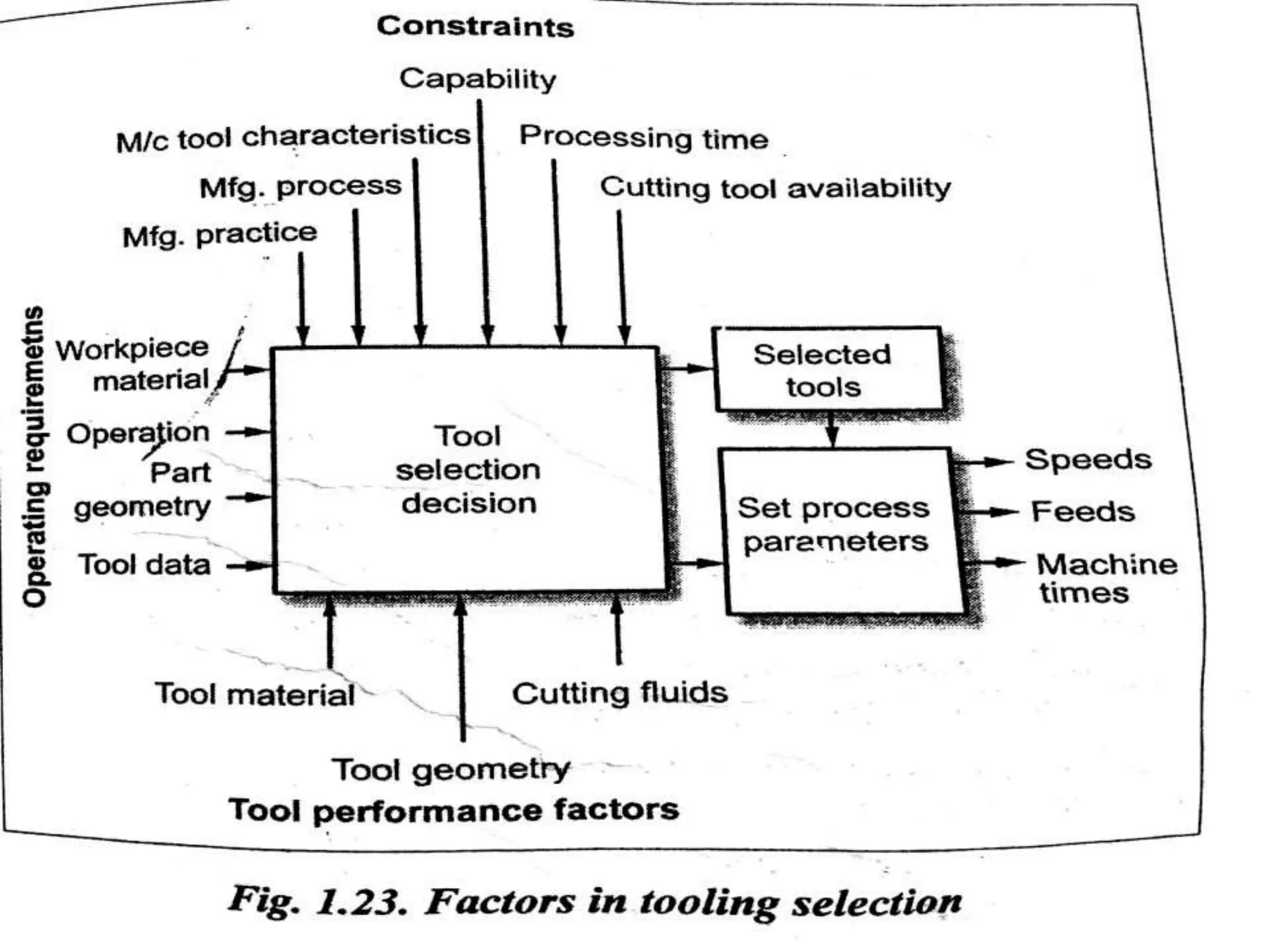

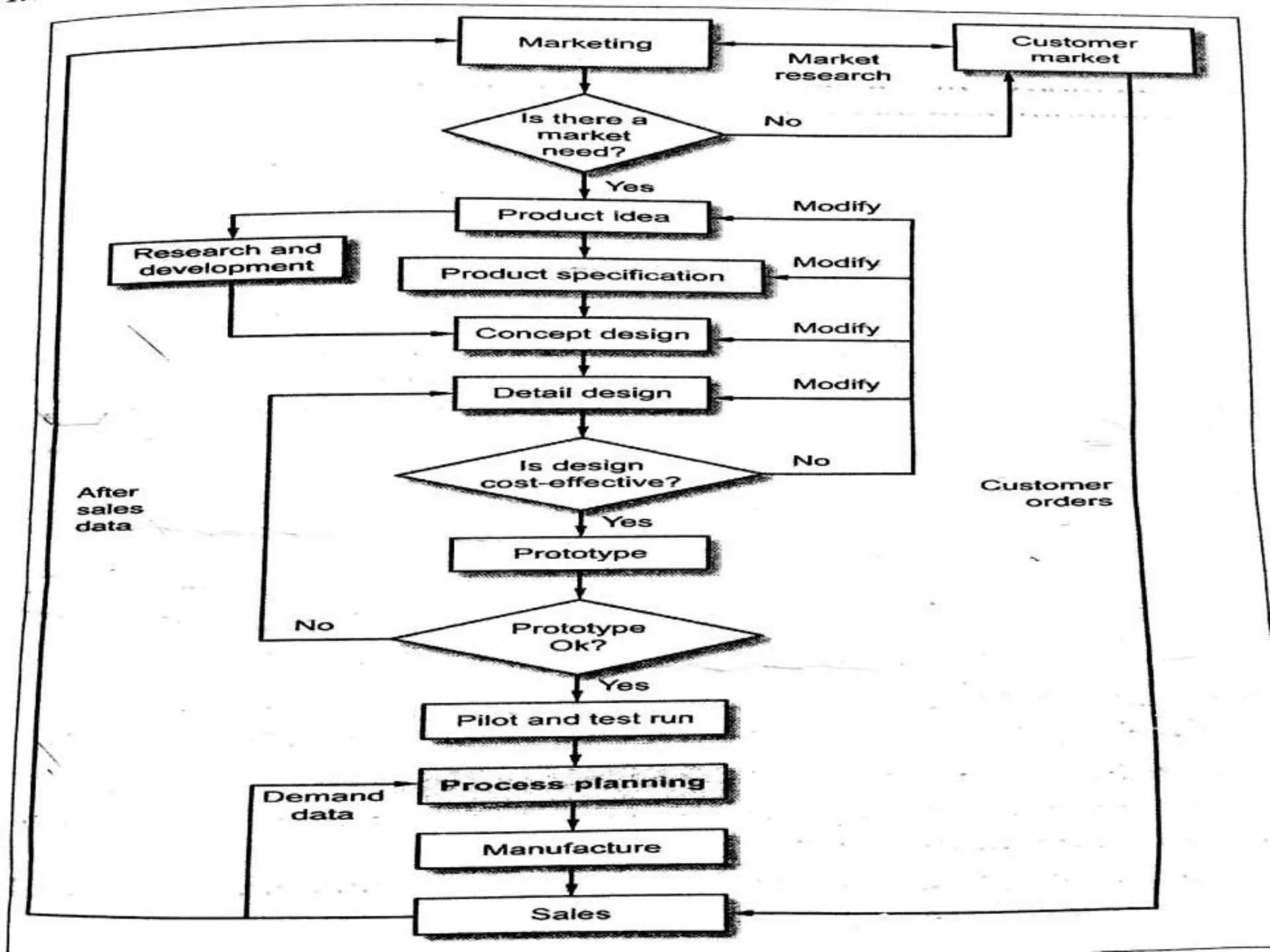

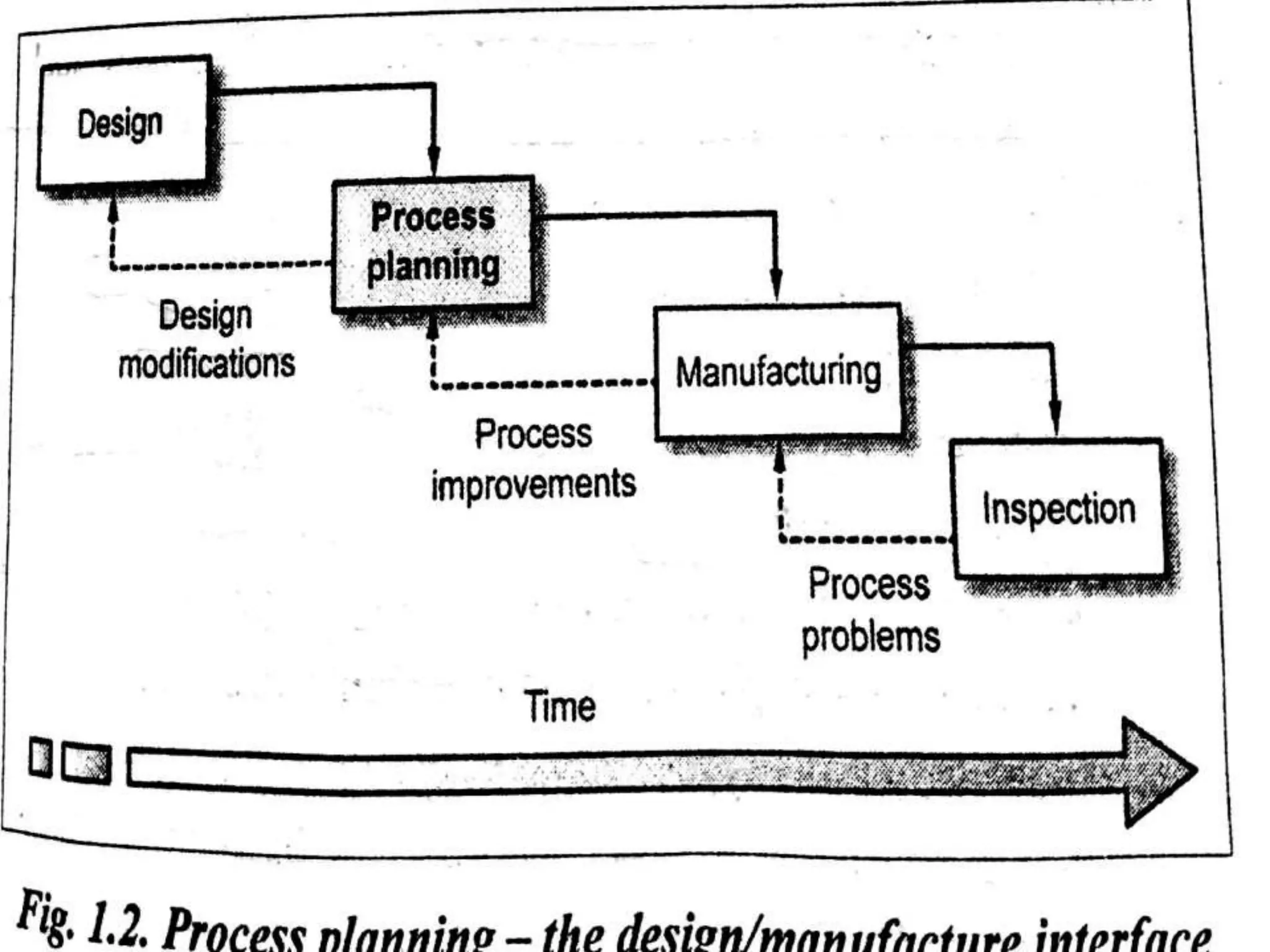

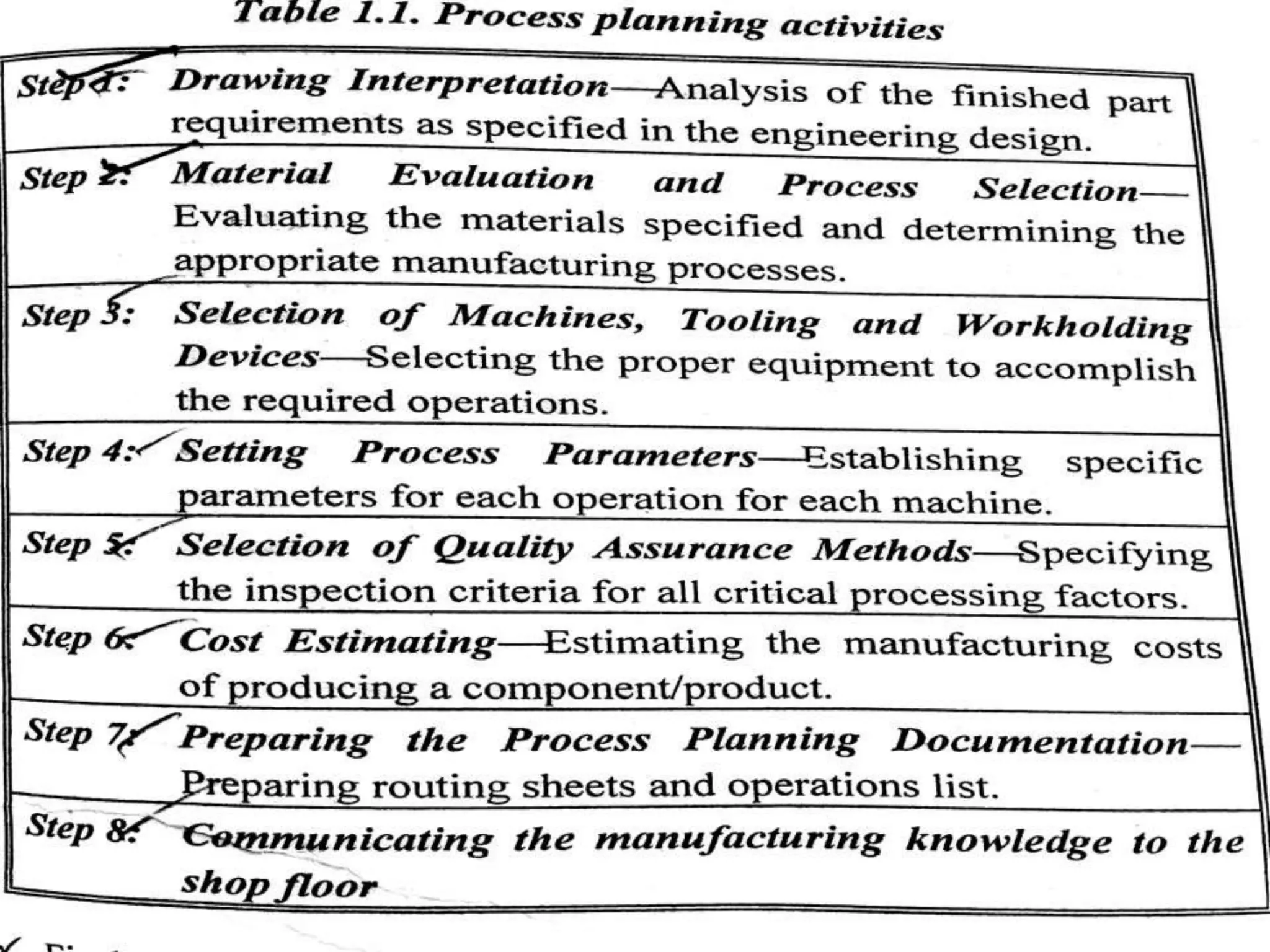

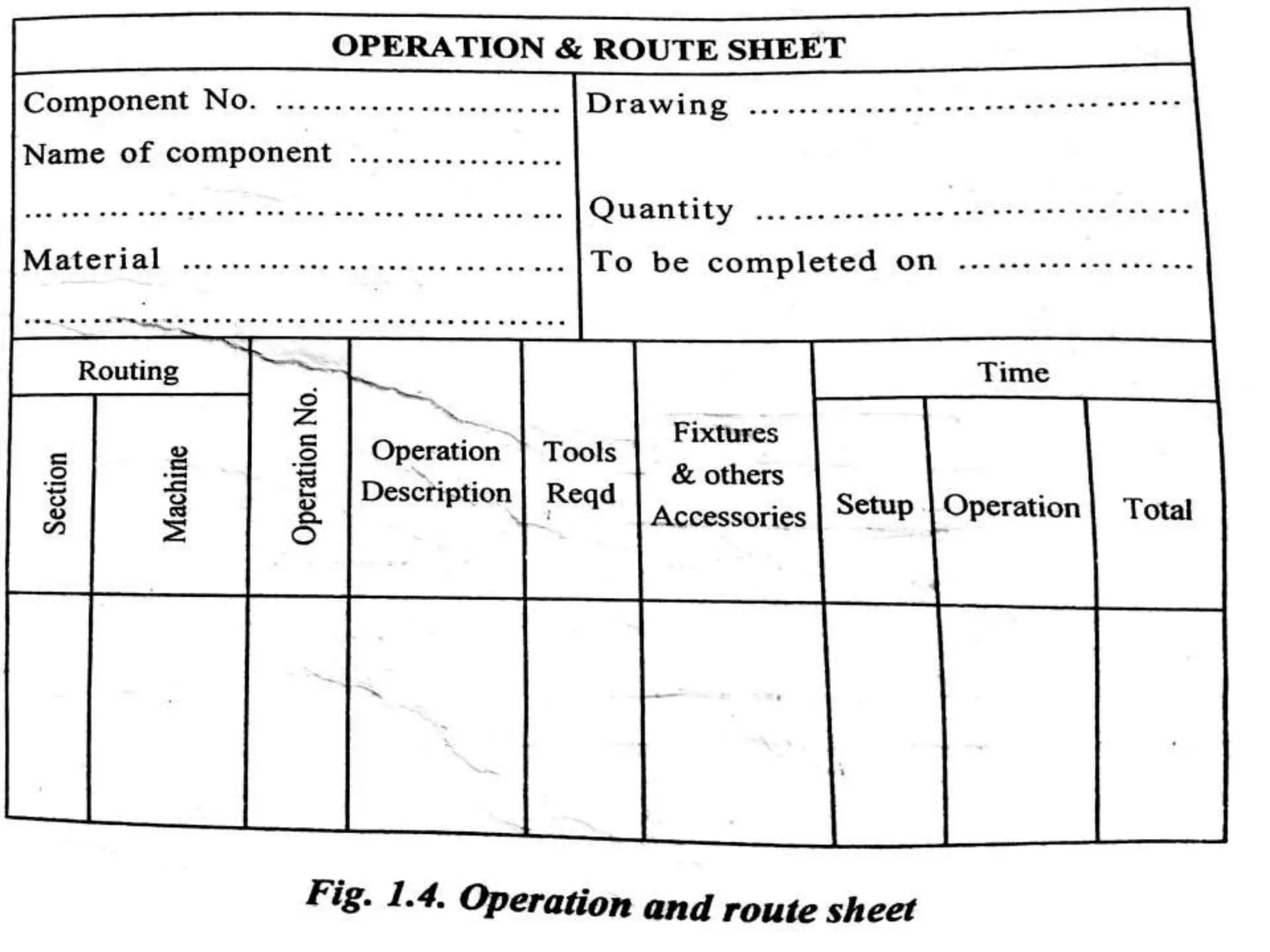

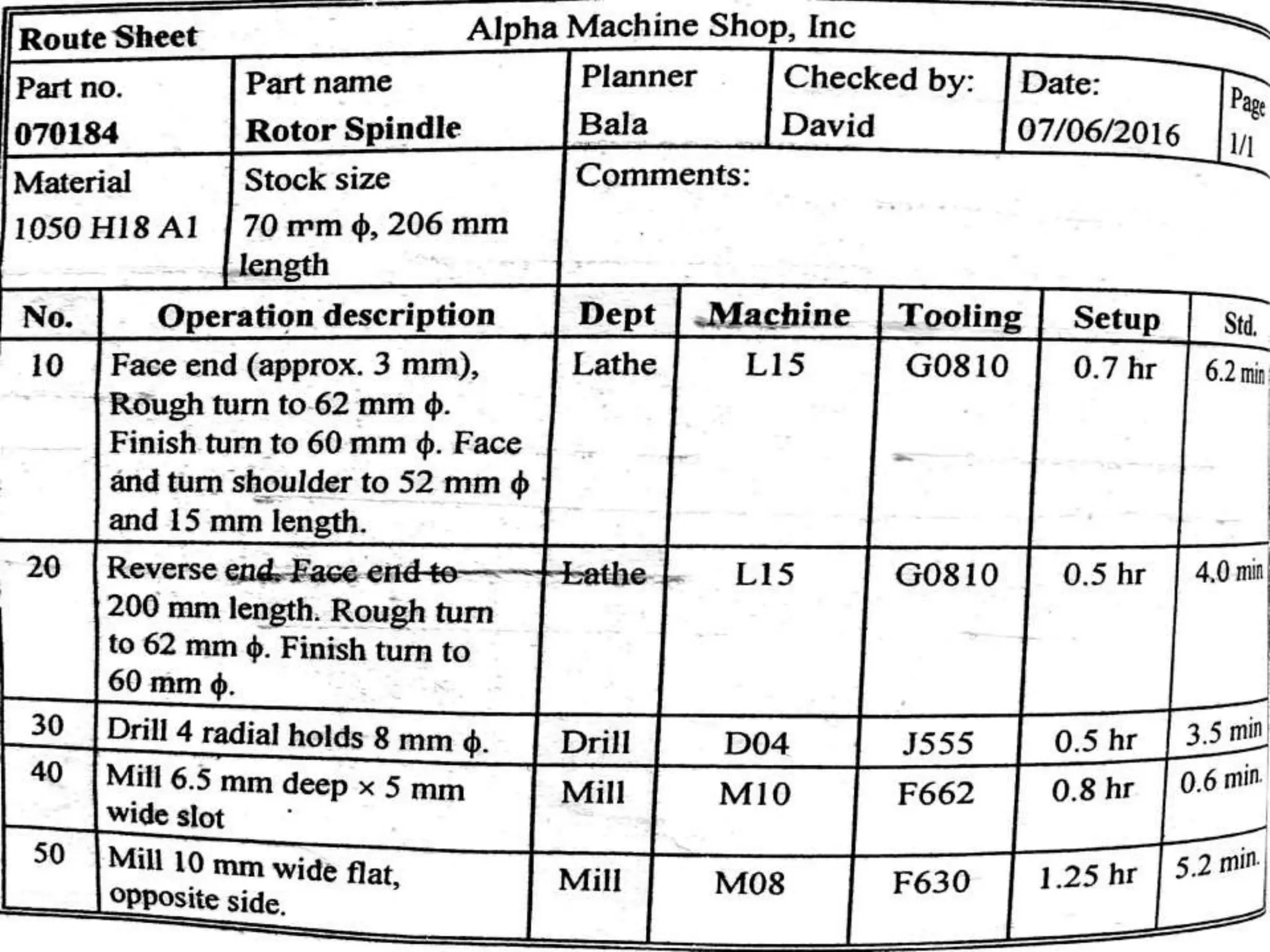

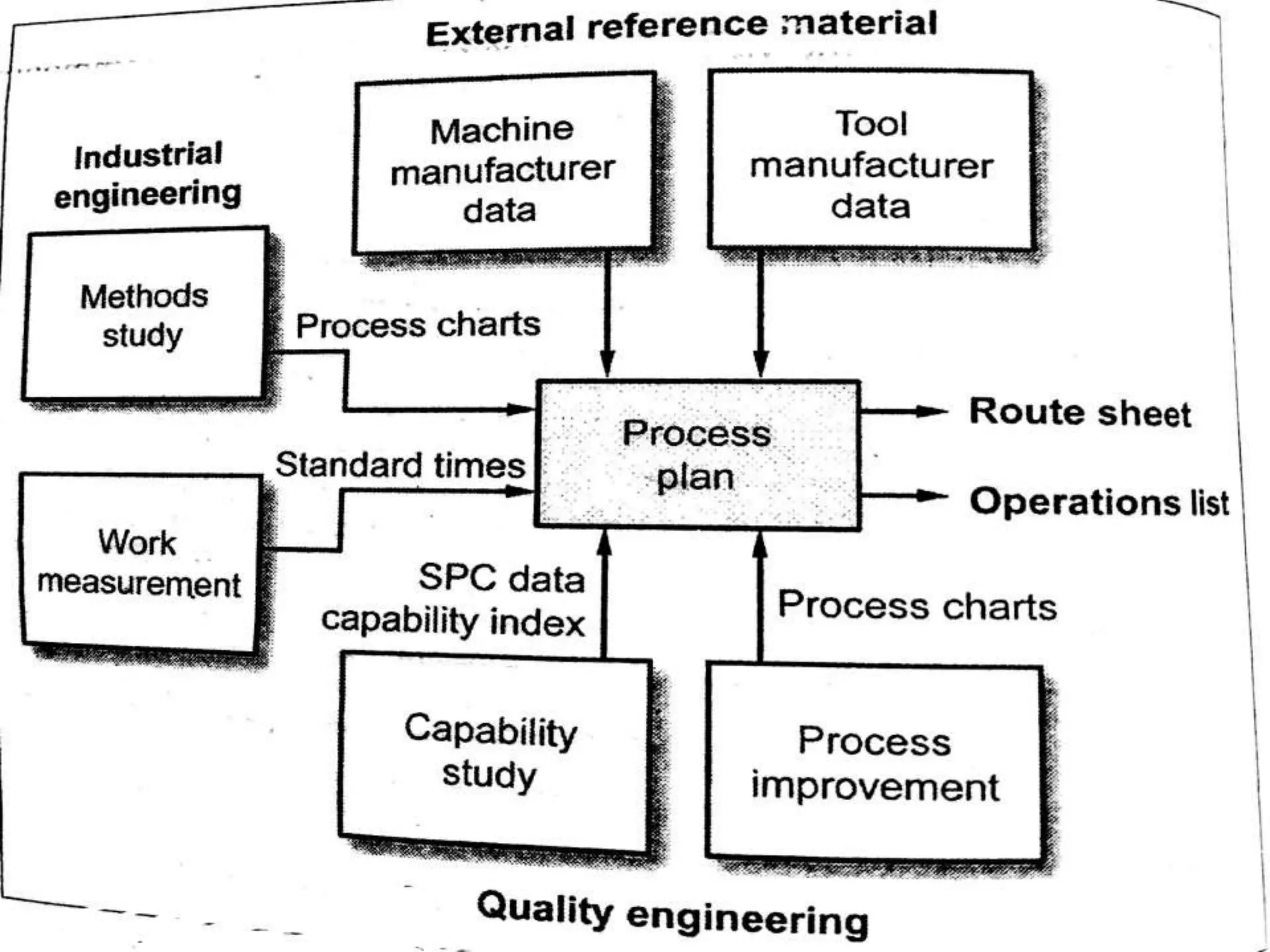

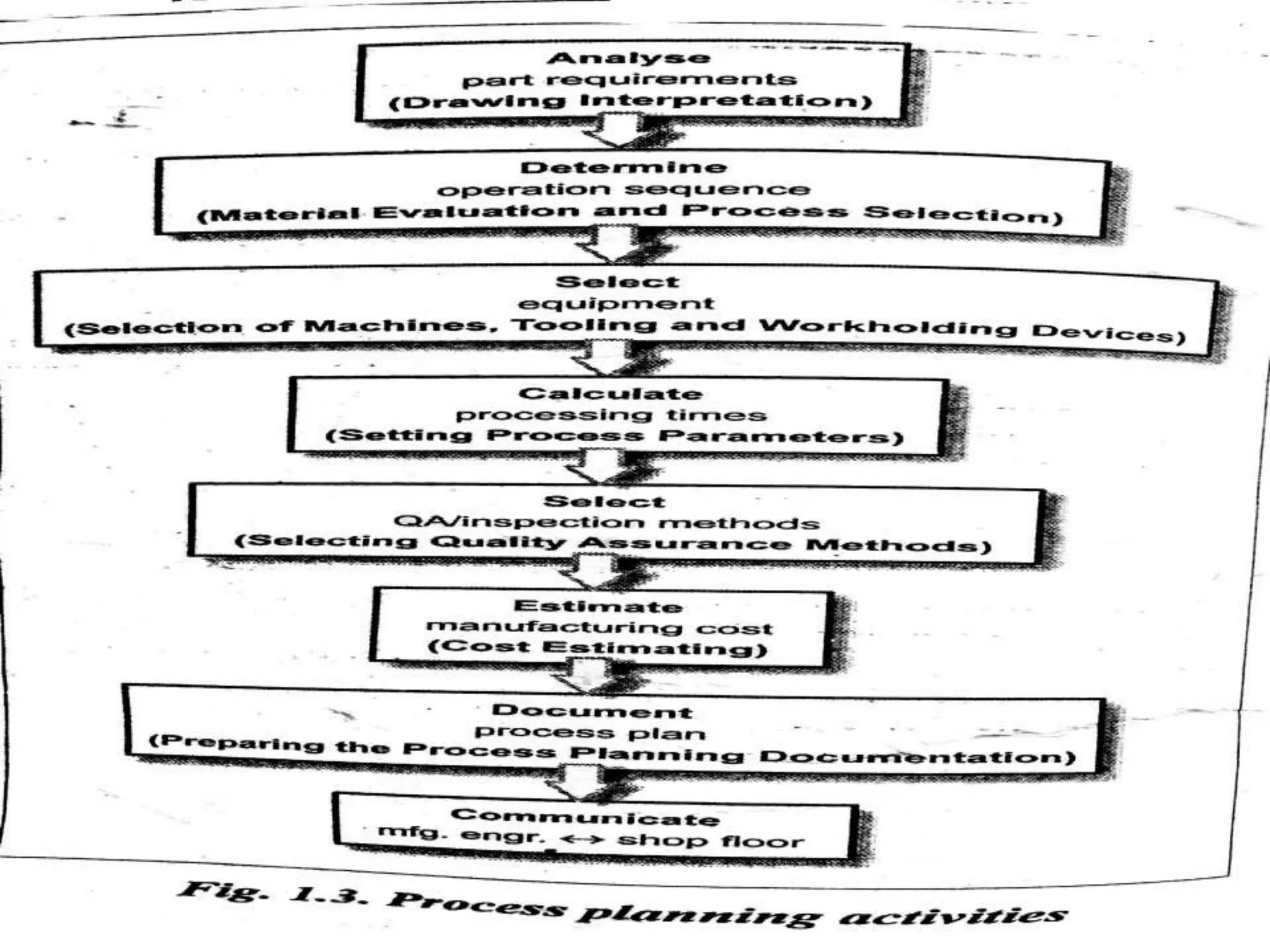

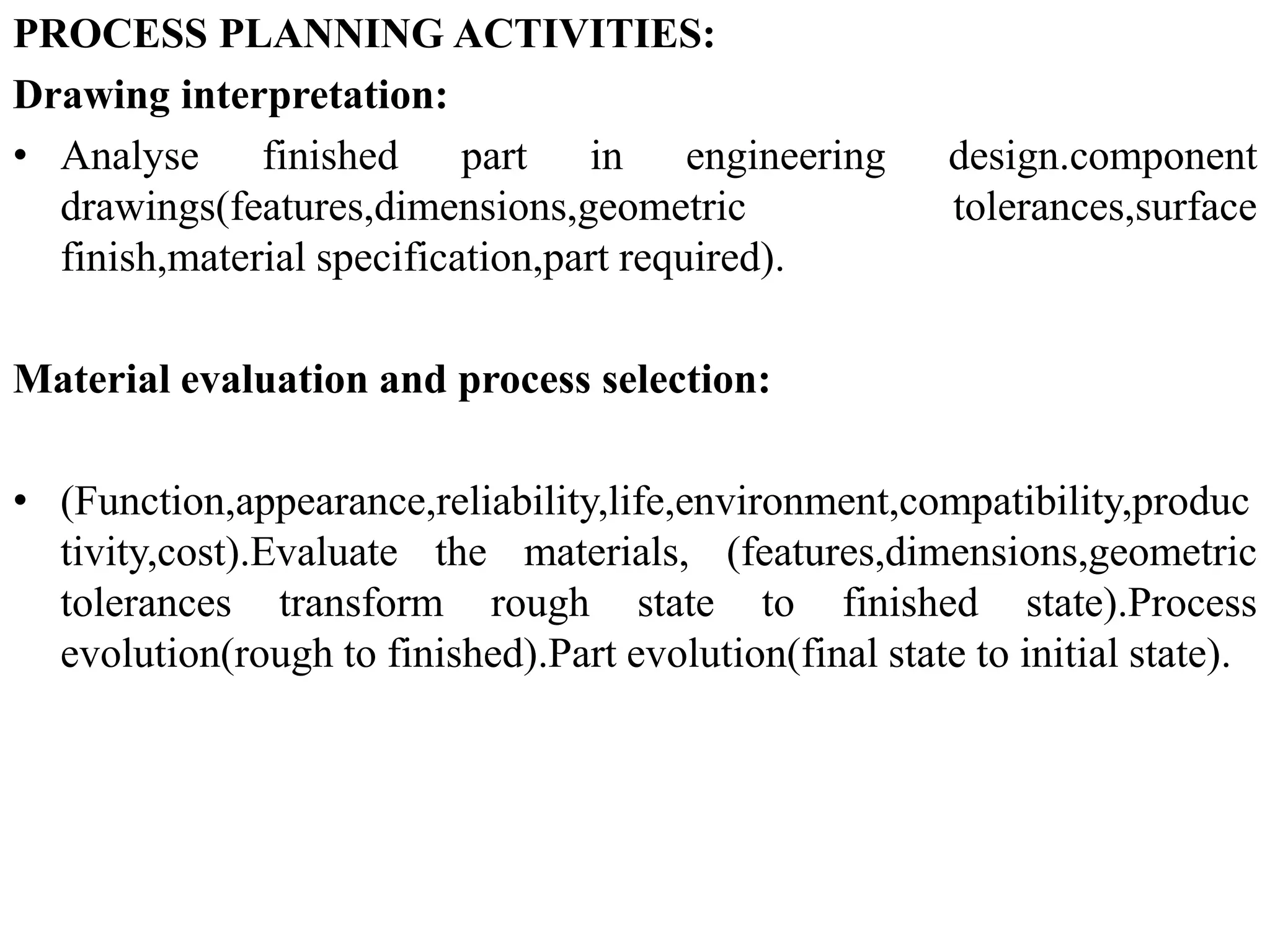

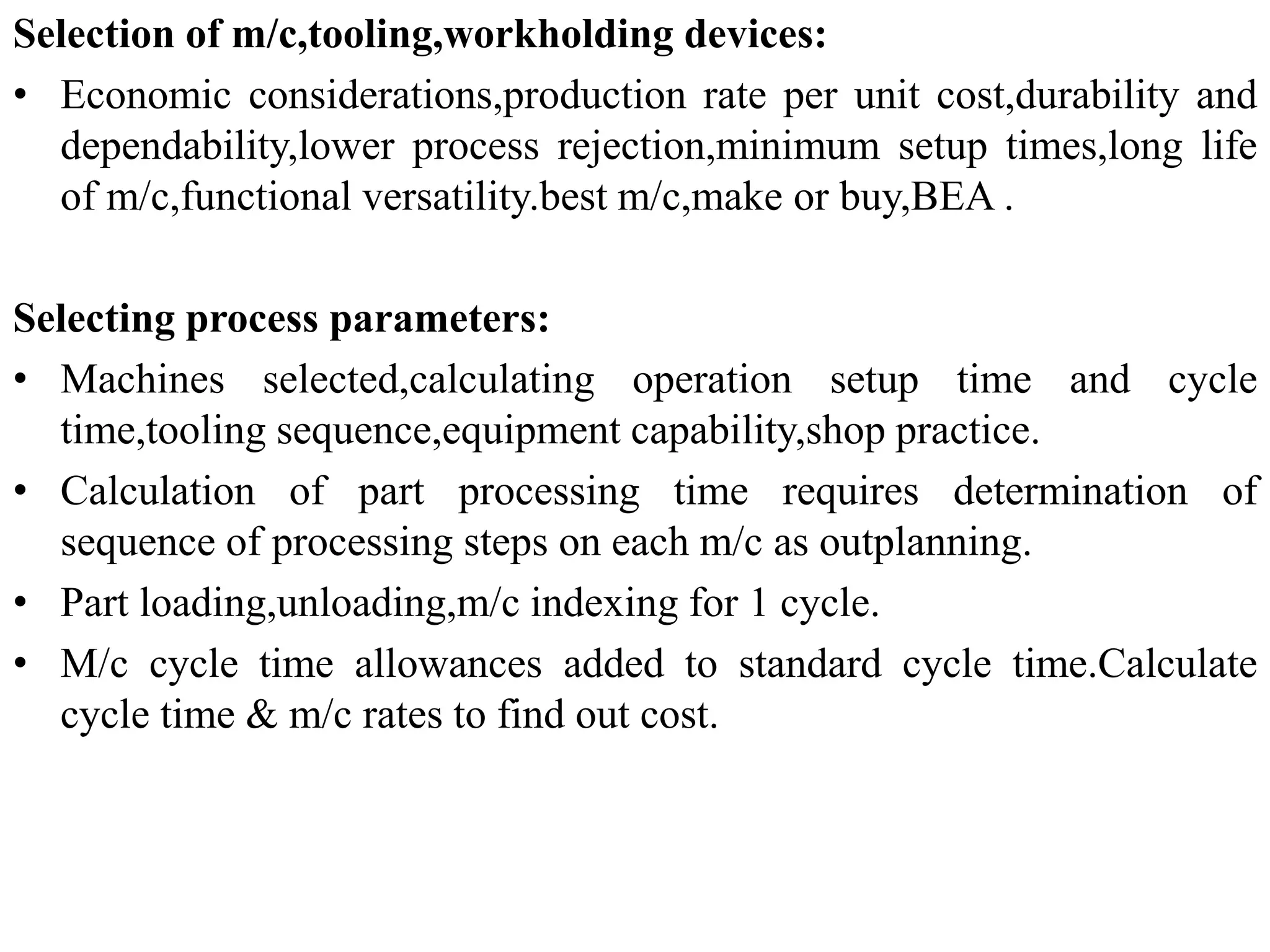

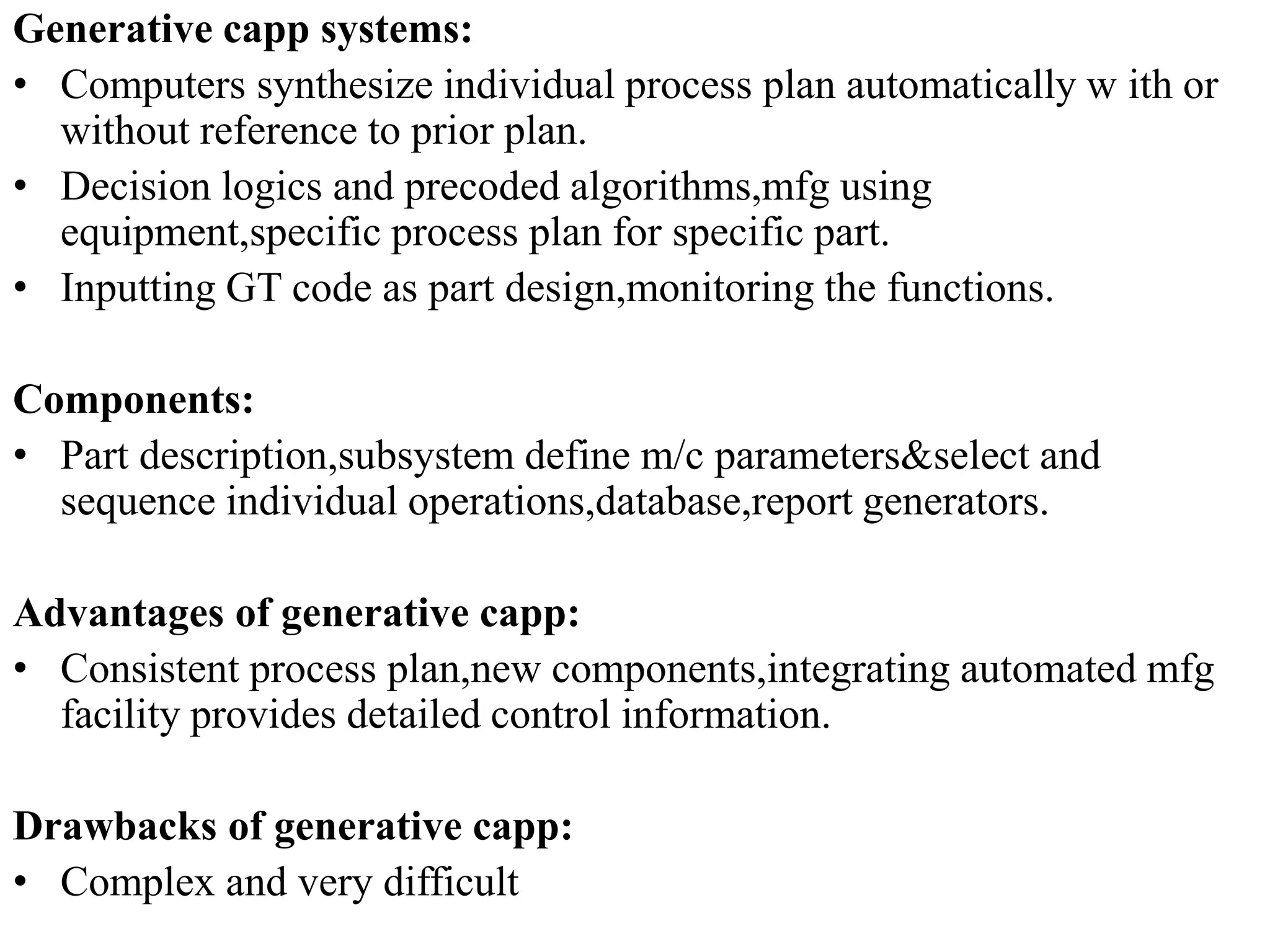

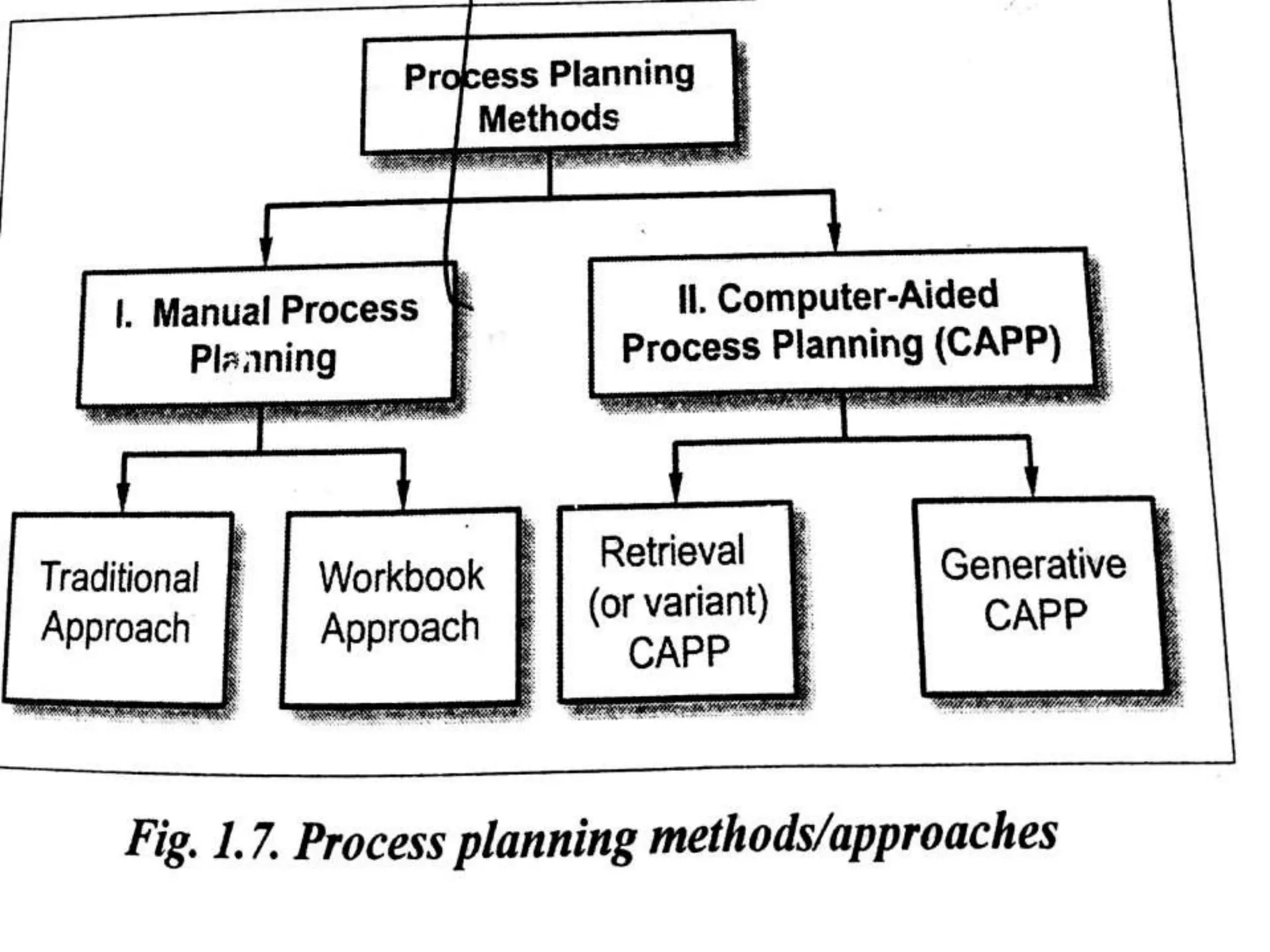

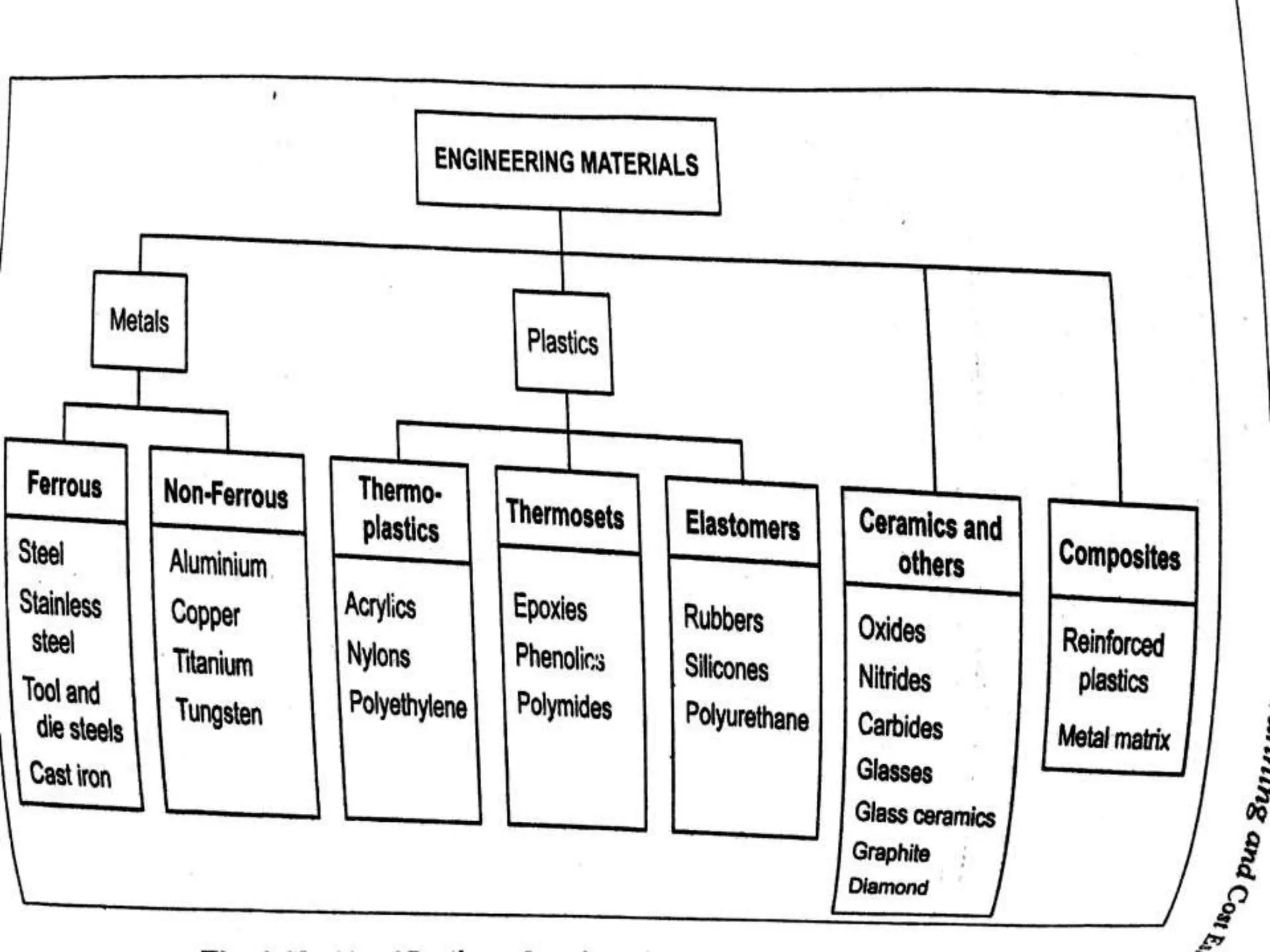

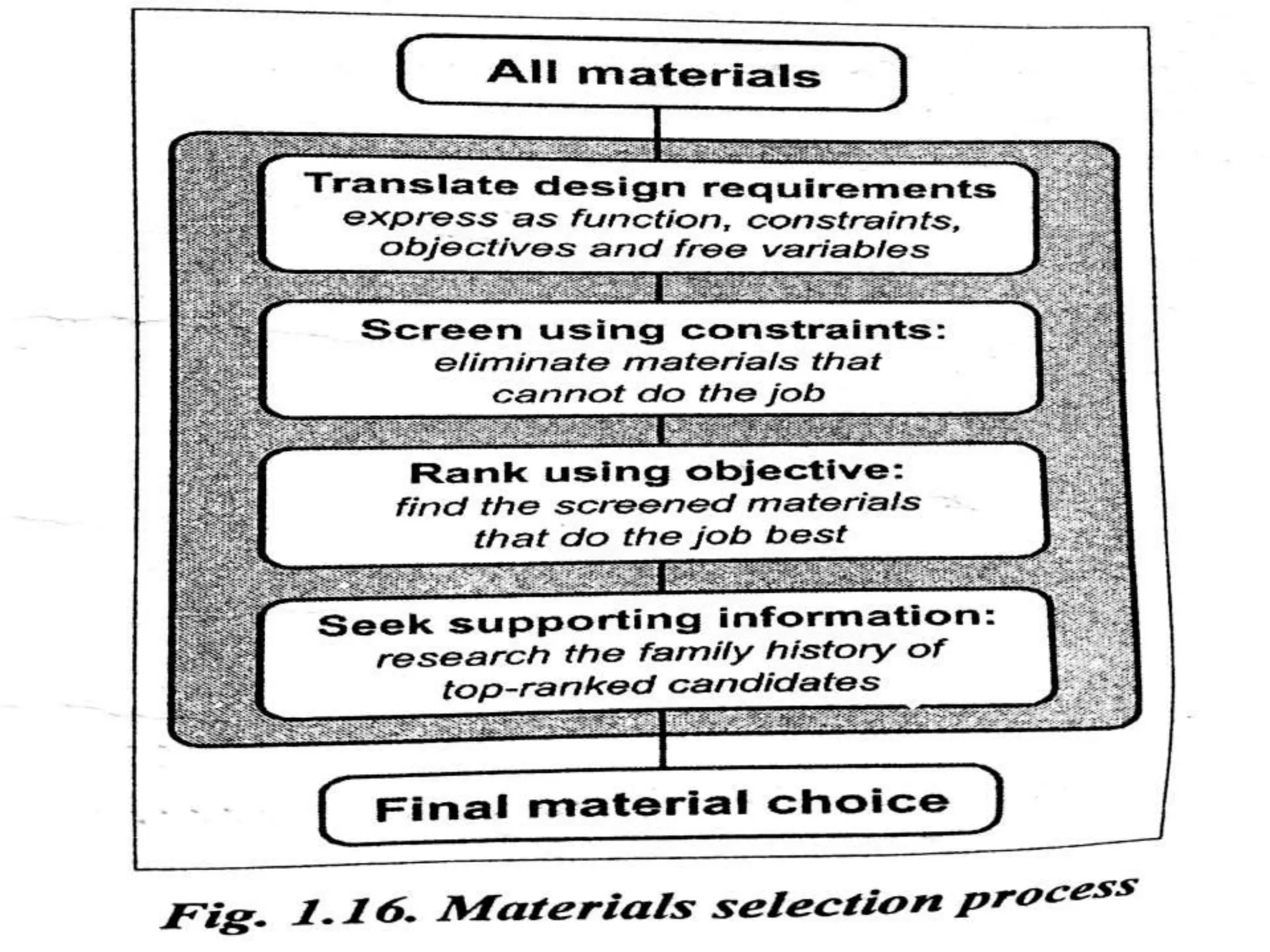

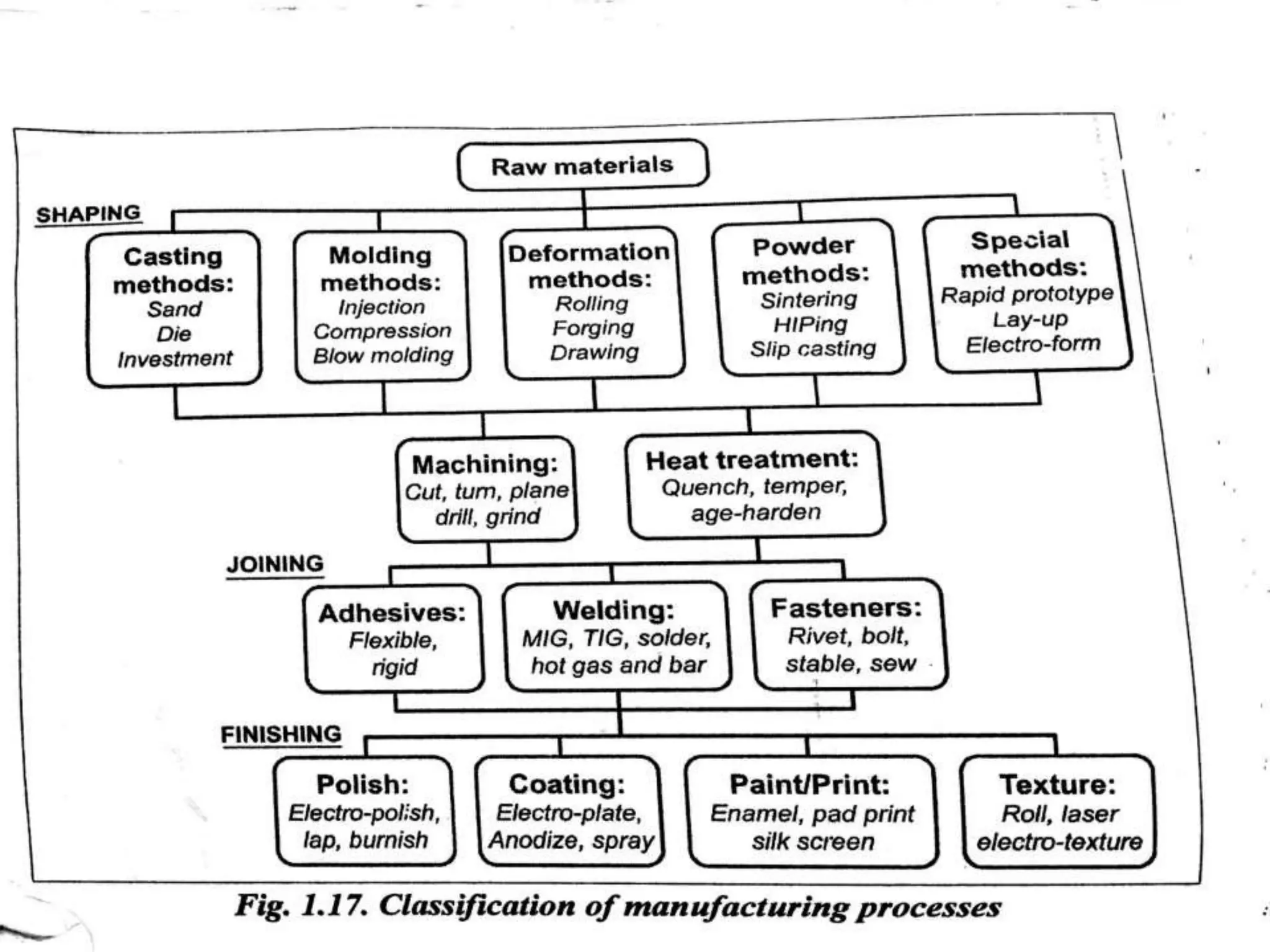

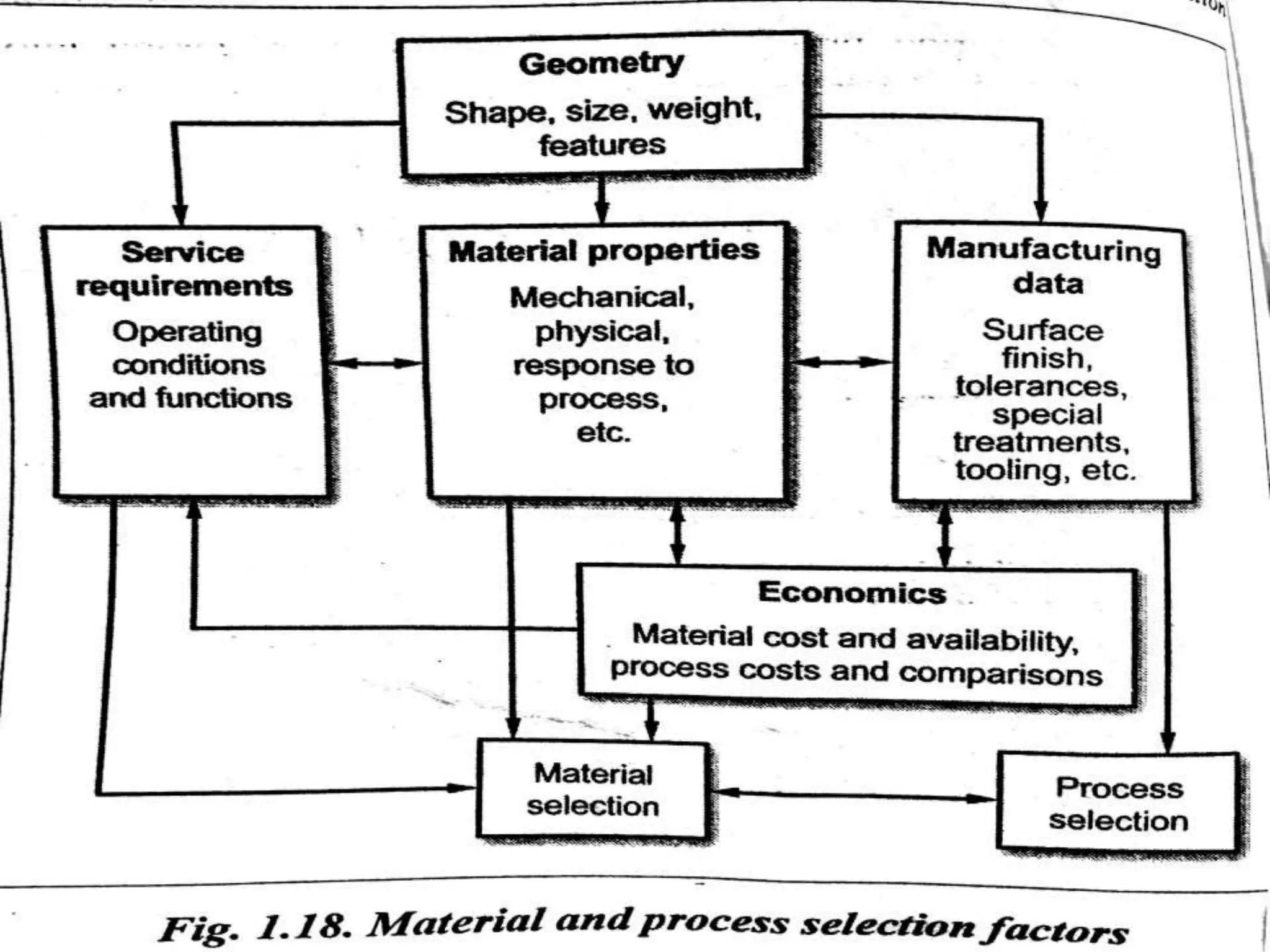

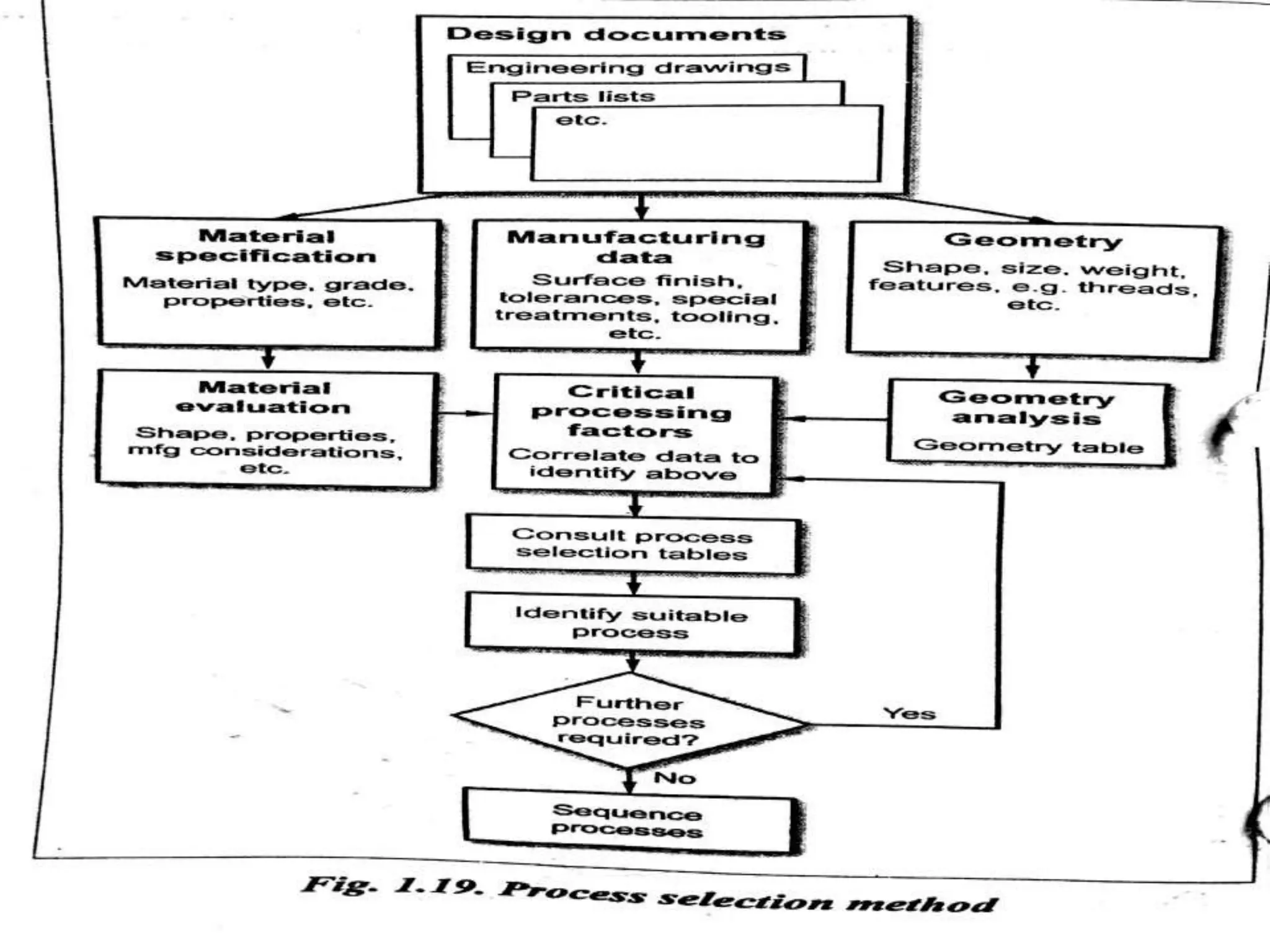

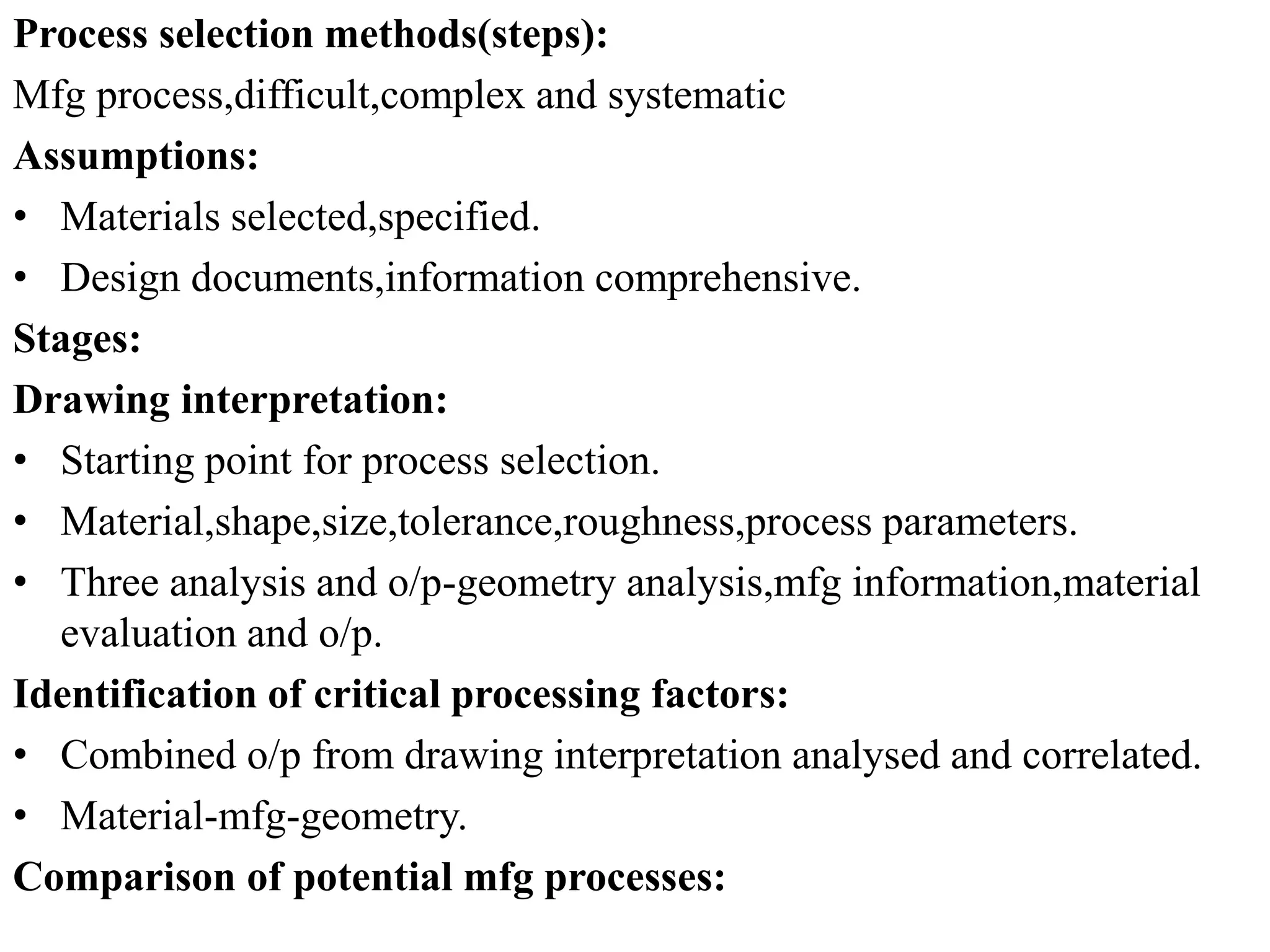

The document discusses process planning, which involves determining the manufacturing processes and operations to produce a product economically. It describes process planning activities like drawing interpretation, material and process selection, and selecting equipment and tooling. Process planning methods can be manual using workbooks or computer-aided. Key factors in process planning include part dimensions, tolerances, materials, production rates, equipment capabilities, and cost. The summary provides a high-level overview of the main topics covered in the document.

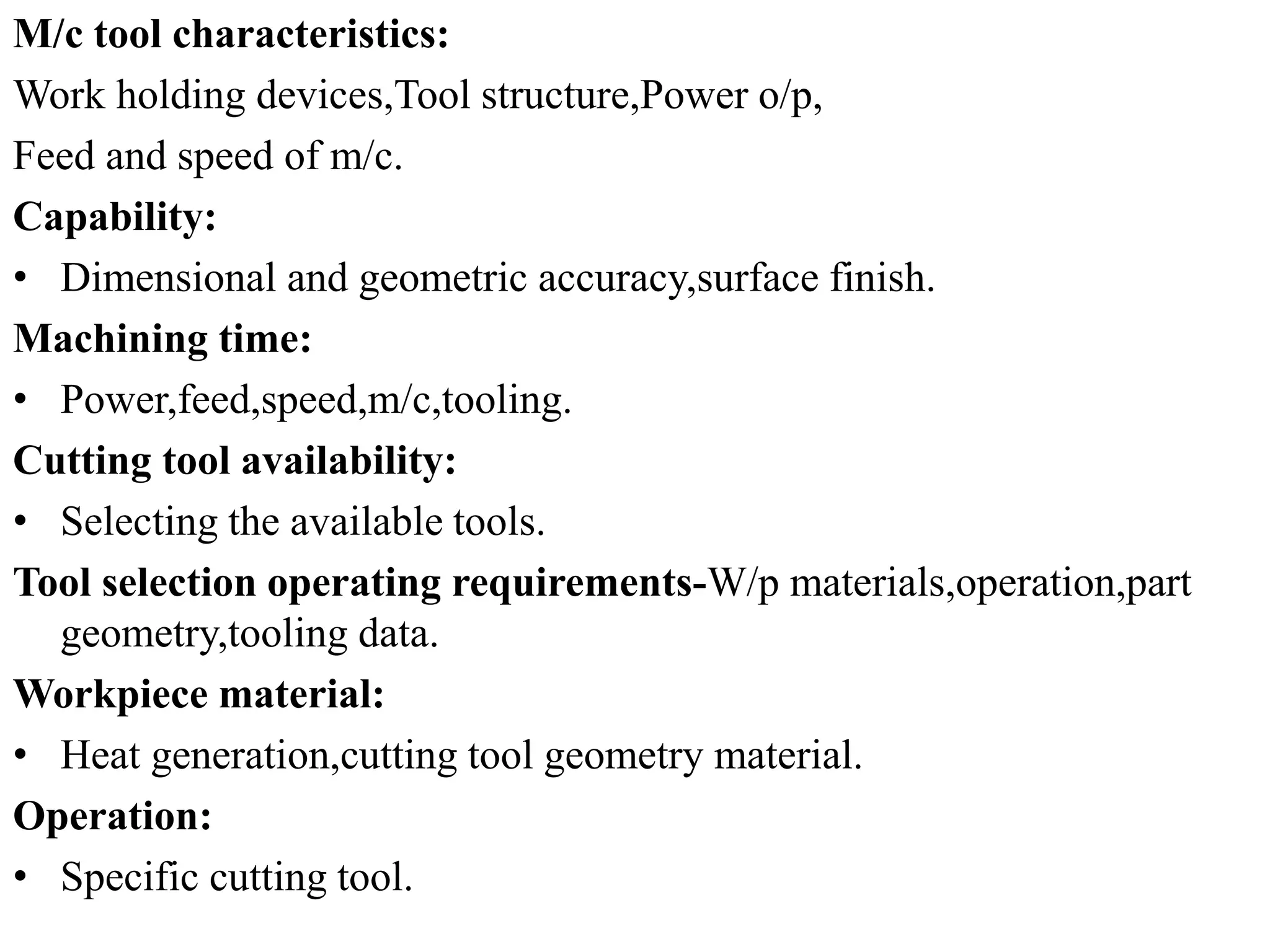

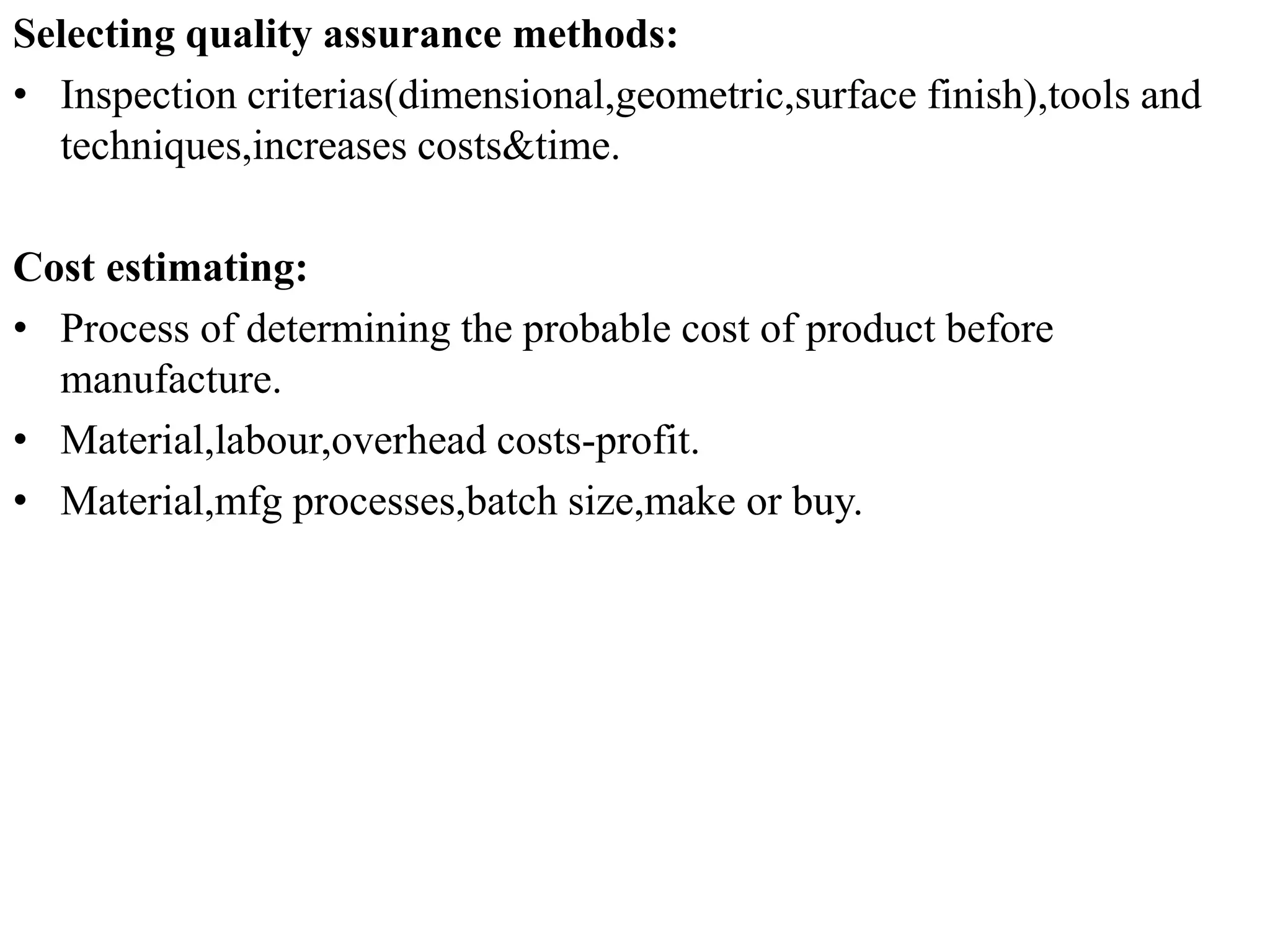

![Surface finish:Capability.

Cutting forces:Feed,speed,depth of cut,opns of m/c tool.

Machine power:Power=cutting forcexcutting speed.

Operational factors: Availability,cost effective,master production

schedule.[Important-batch size,capacity,availability].

Batch size: EBQ calculated,potential economical m/c tool.

Capacity:Production rate,acheives o/p,mps.

Availability:Proportion,performance,efficiency,reliability,

Availability.](https://image.slidesharecdn.com/ppceunit-1-220122035220/75/INTRODUCTION-TO-PROCESS-PLANNING-58-2048.jpg)