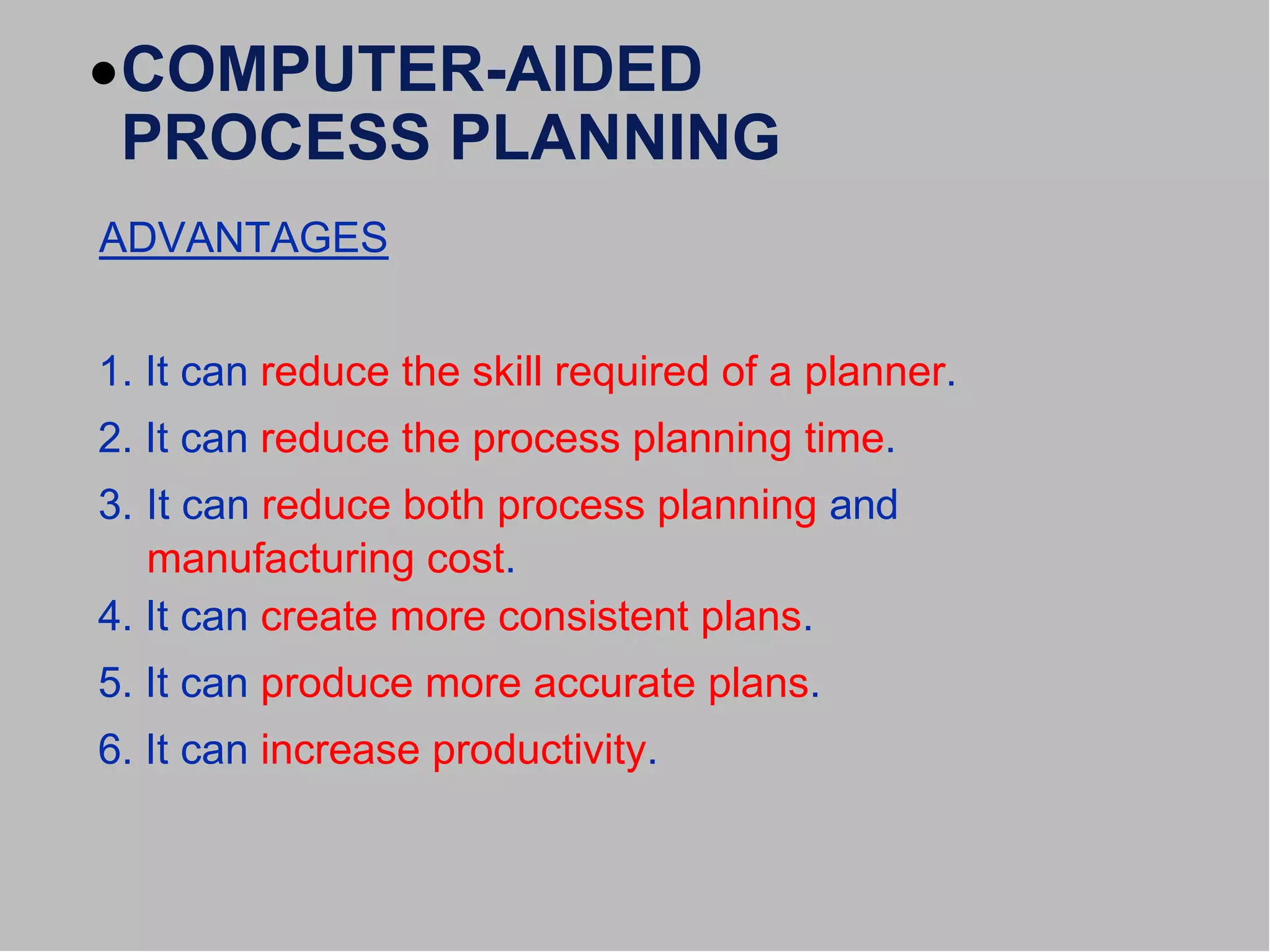

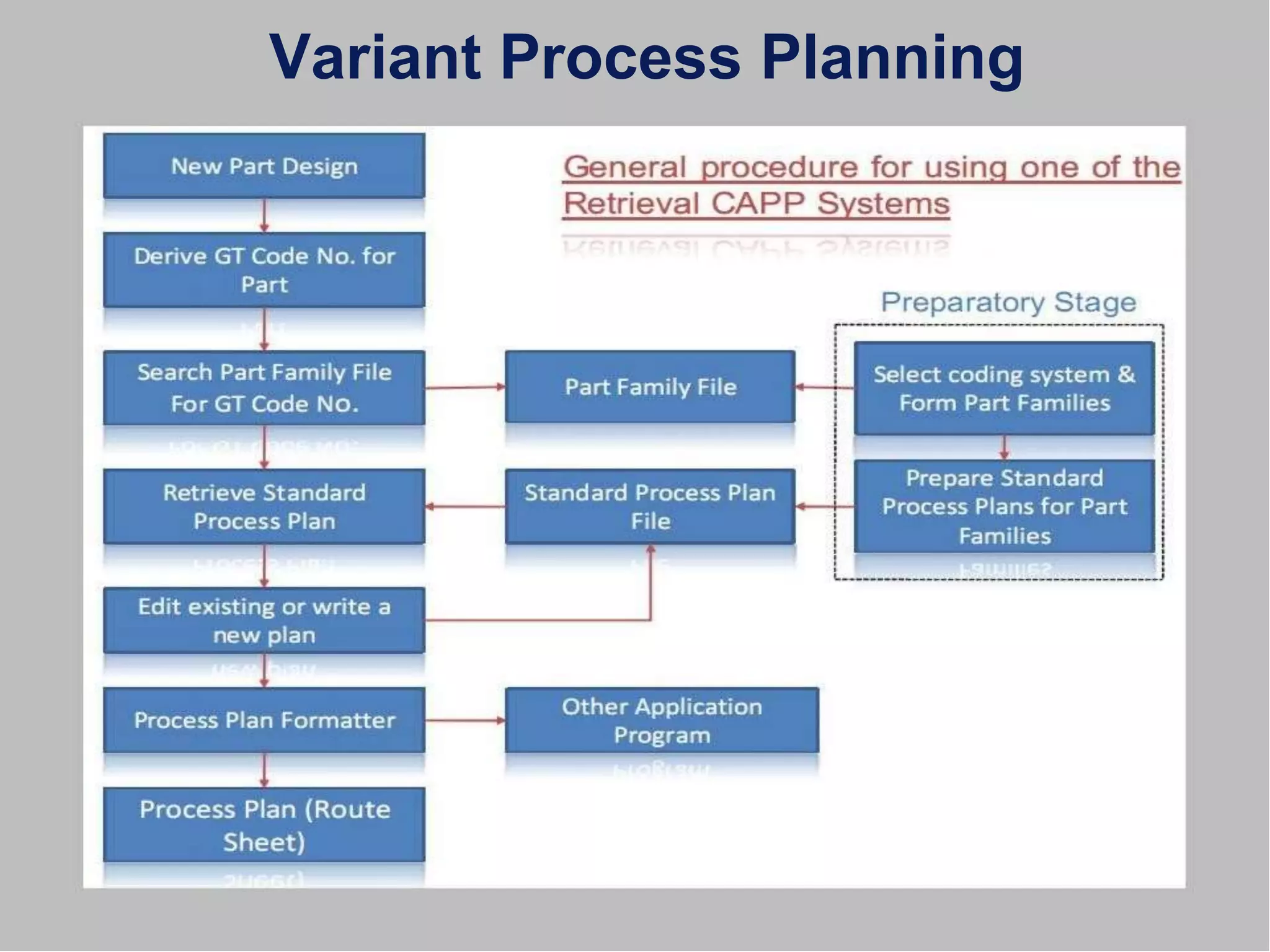

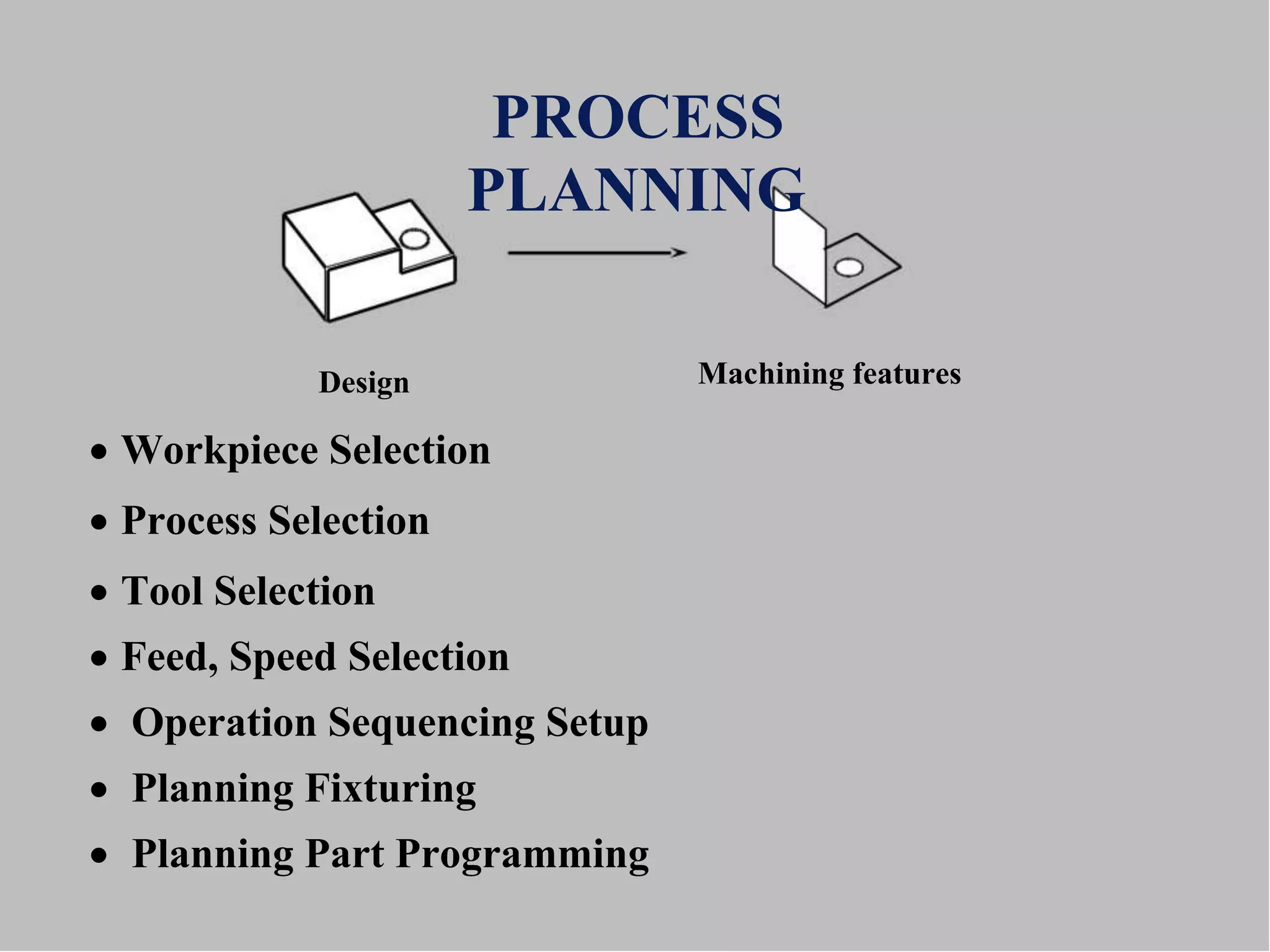

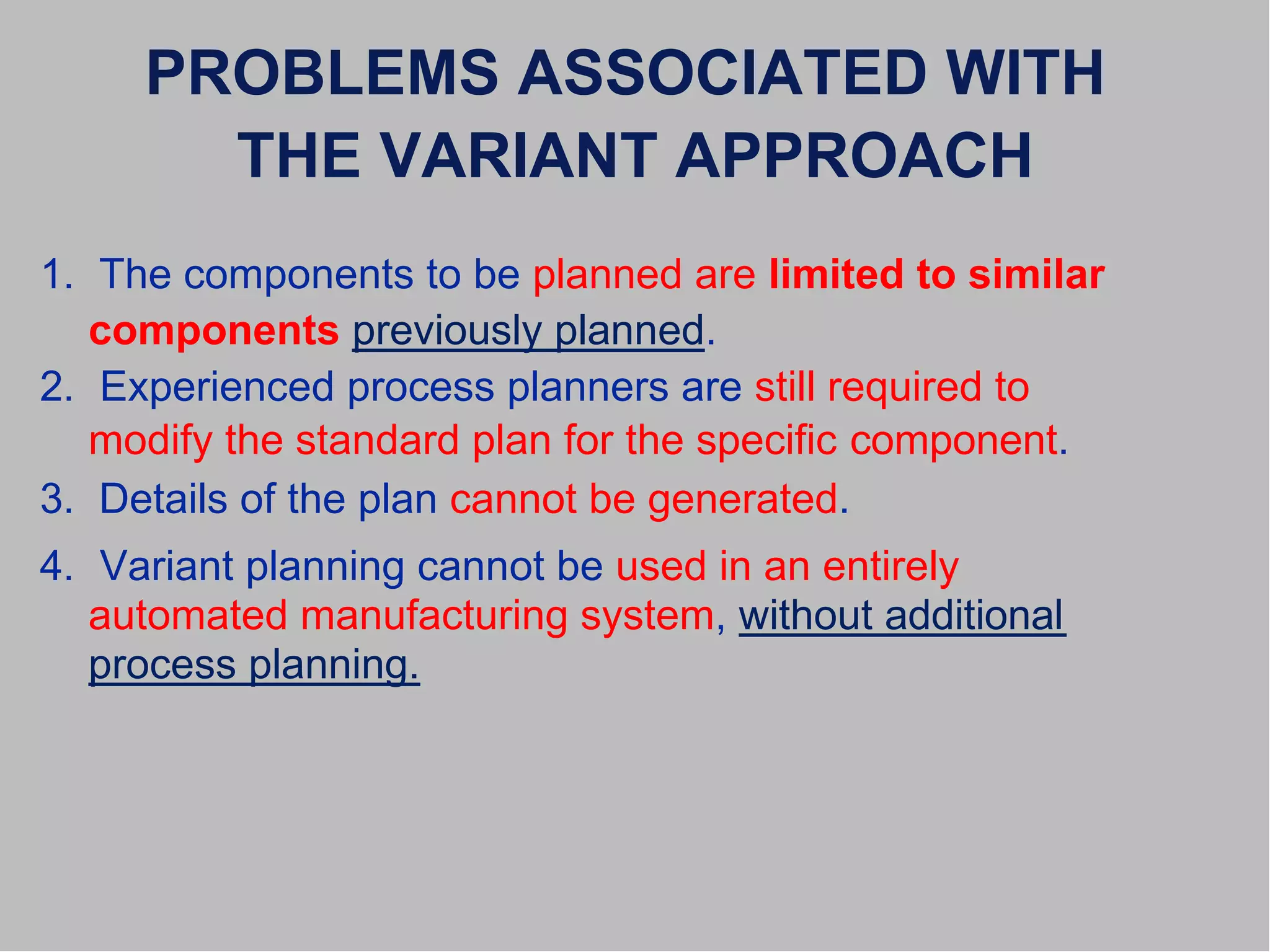

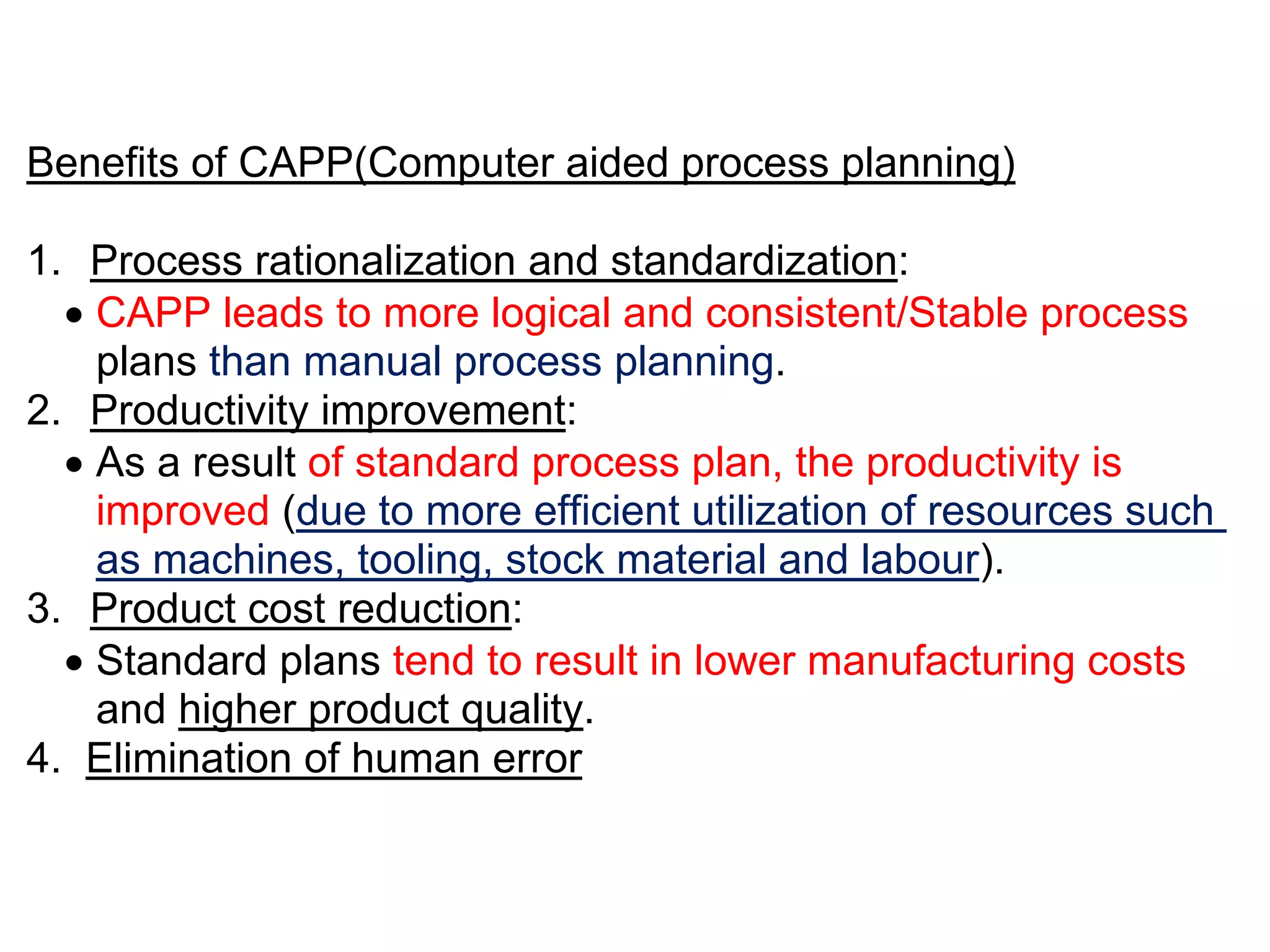

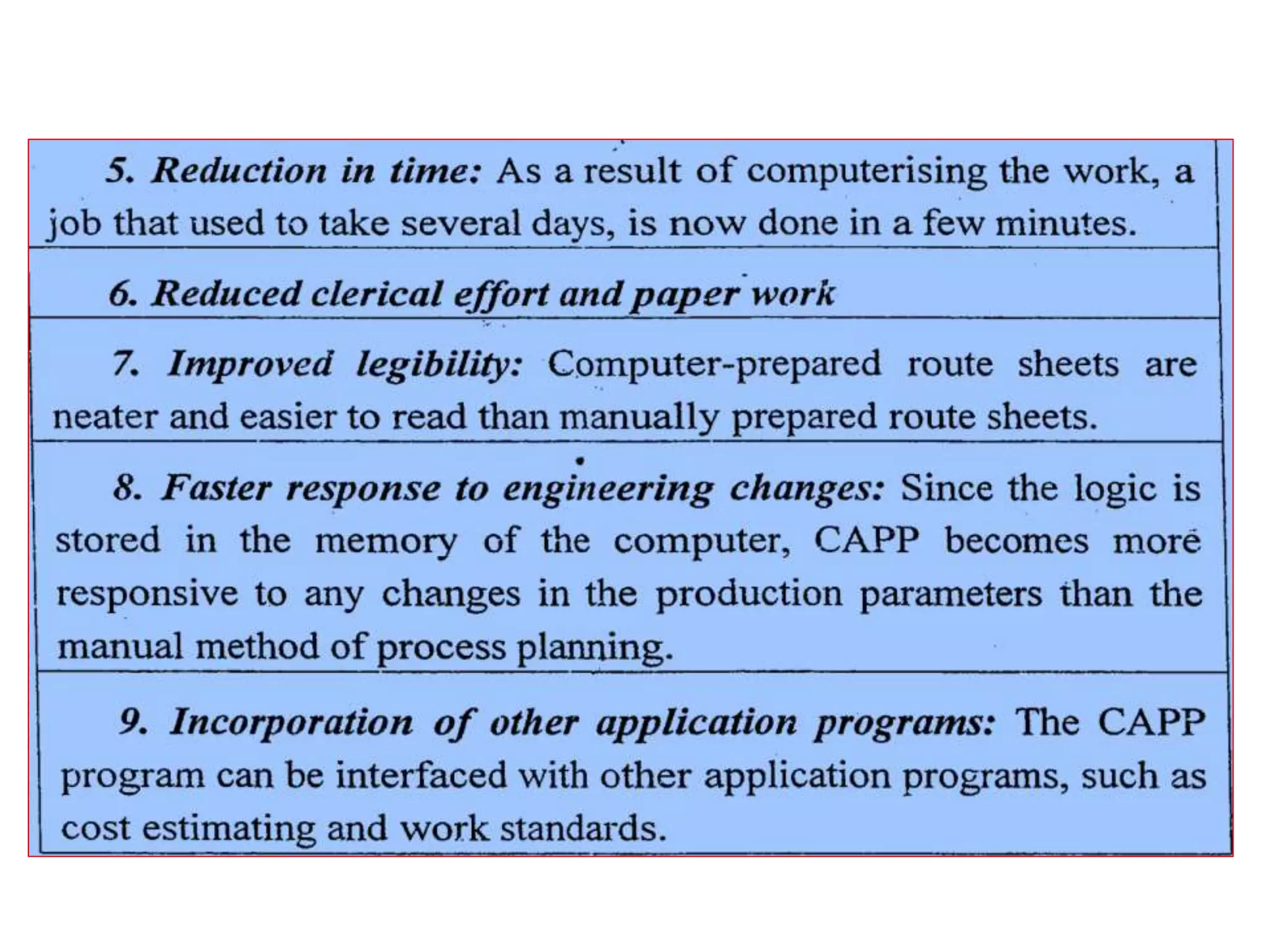

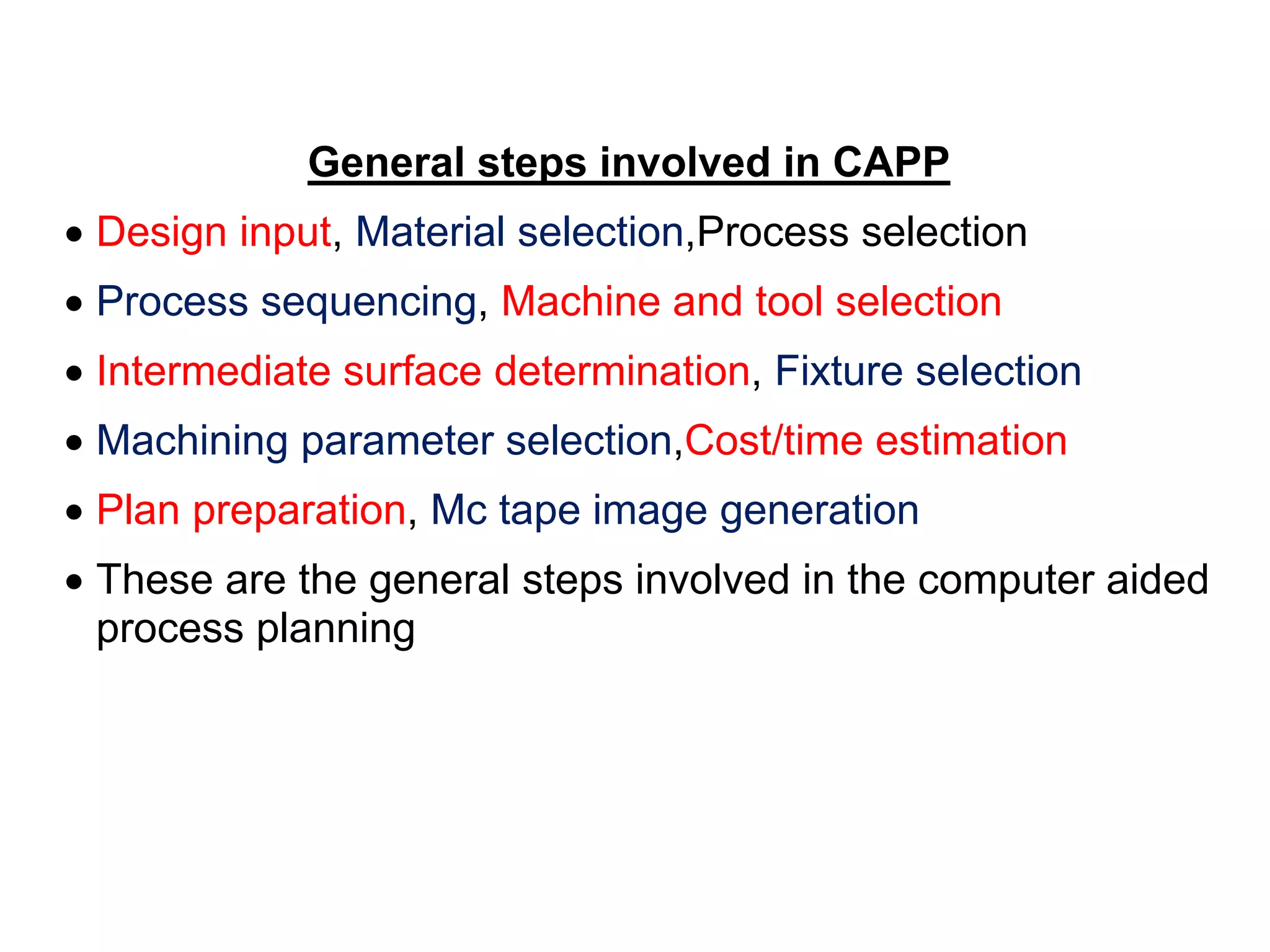

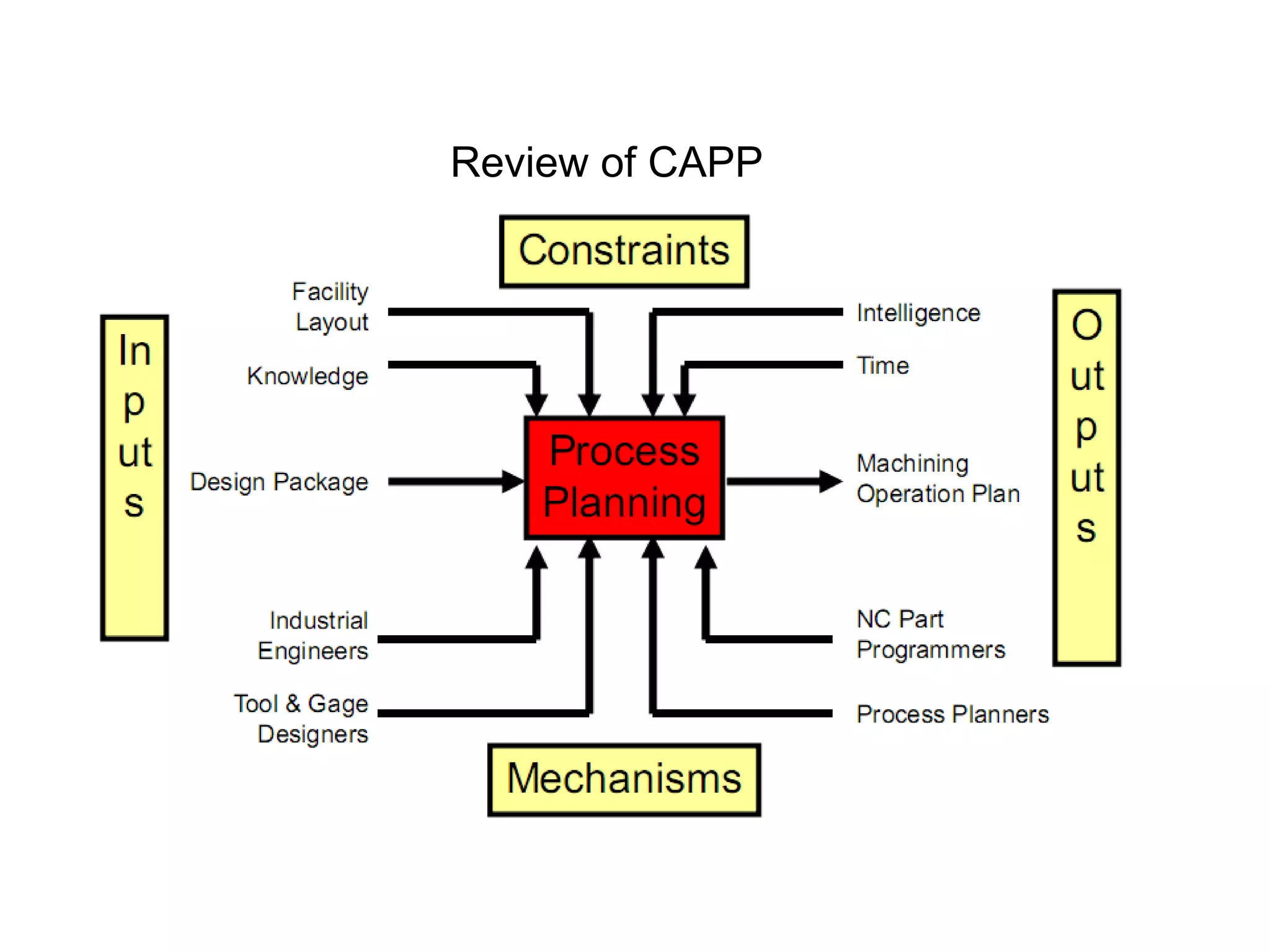

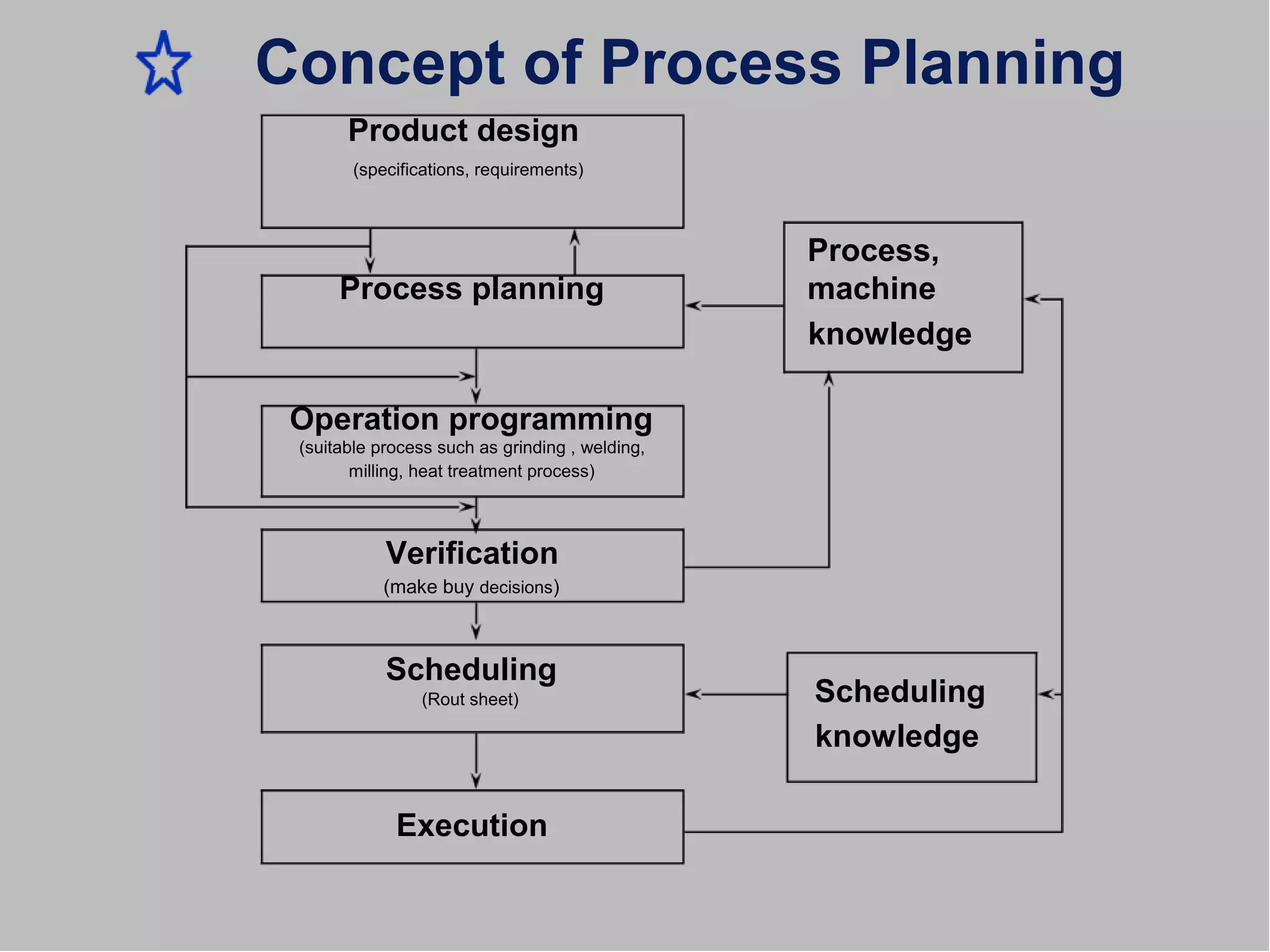

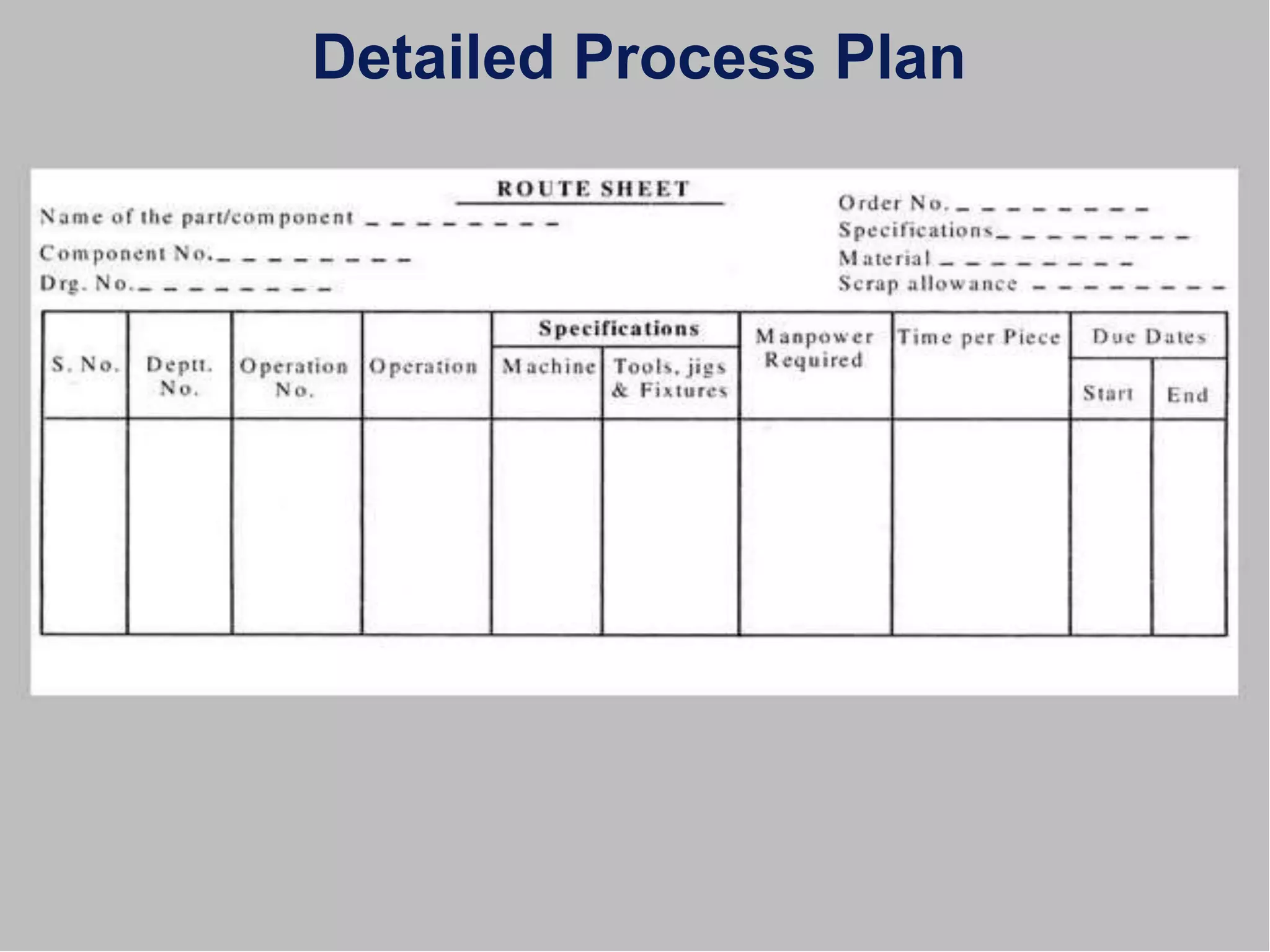

Process planning involves determining the optimal methods for manufacturing a product economically and competitively. It includes devising and selecting processes, machine tools, and specifying parameters to convert raw materials into finished goods. Process planning results in a process plan (or route sheet) that details the specific operations, machines, tools, fixtures, processing times, and sequence of operations required for production. Computer-aided process planning (CAPP) utilizes computer software and databases to automate the generation of process plans and has advantages over manual process planning such as increased productivity, reduced costs, and more consistent plans.

![Process Planning Activities

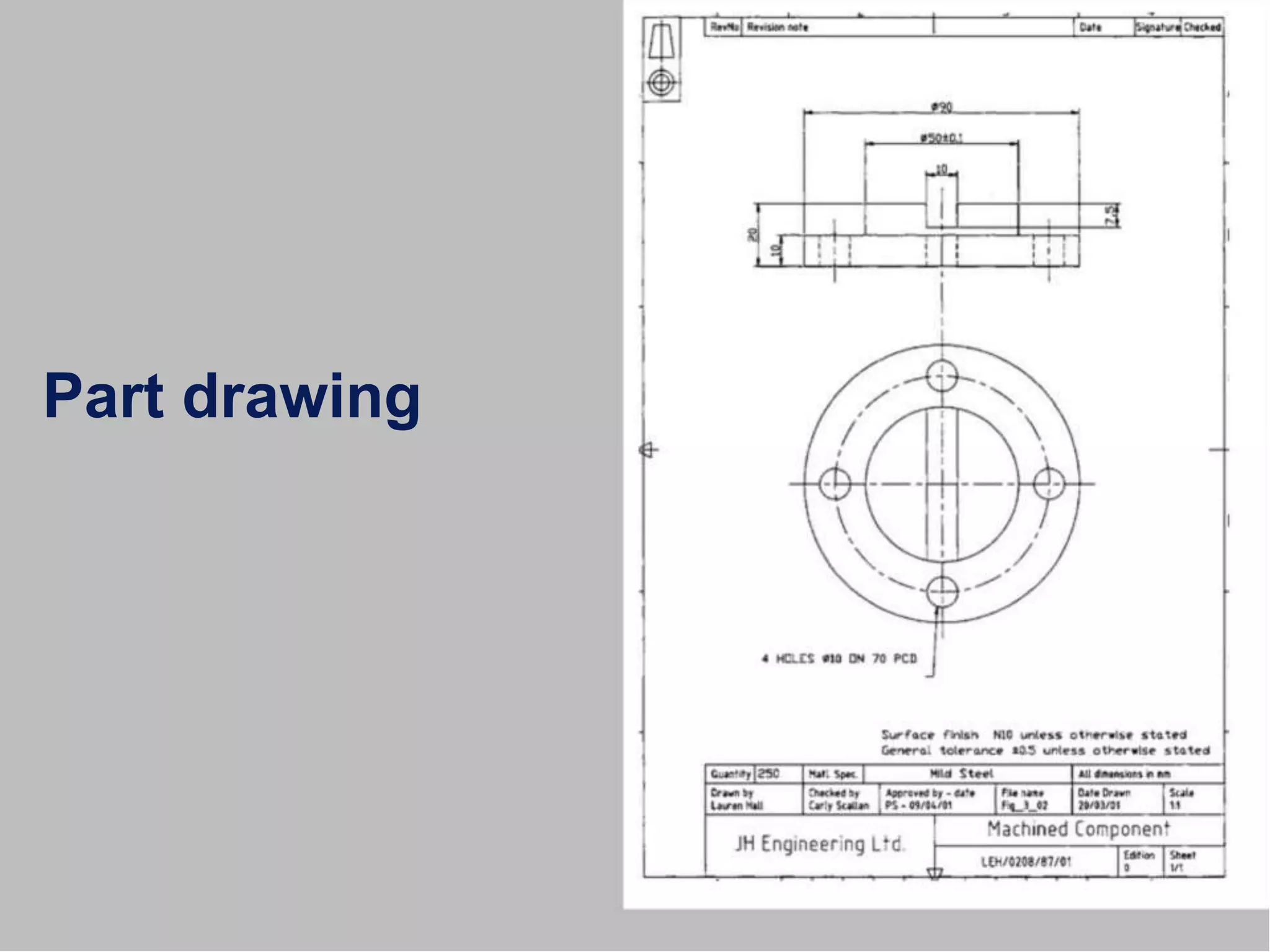

Analyse (Part ,dimension requirements) [DRAWING INTERPRETATION]

Determine (operation sequence) [MATERIAL EVALUATION AND PROCESS SELECTION]

Select (equipment ) [SELECTION OF MACHINES . TOOLING and WORK HOLDING DEVICE]

Calculate (processing times ) [SETTING PROCESS PARAMETERS]

Select (QA/Inspection methods) [SELECTING QUALITY ASSURANCE METHOD]

Estimate (manufacturing cost) [COST ESTIMATING]

Document (Process Plan ) [PREPARING PROCESS PLANNING DOCUMENTATION]

Communicate (manufacturing Engineer with shop floor)](https://image.slidesharecdn.com/1-unitintroductiontoprocessplanning-converted-230816093929-4cd4cb01/75/1-unit-Introduction-to-process-planning-converted-docx-6-2048.jpg)