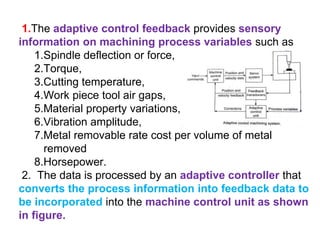

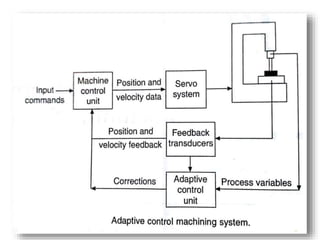

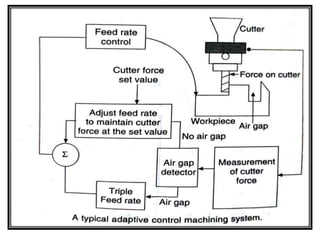

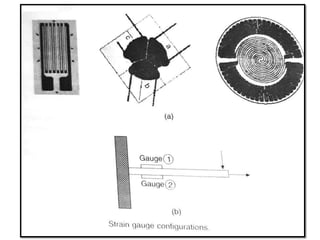

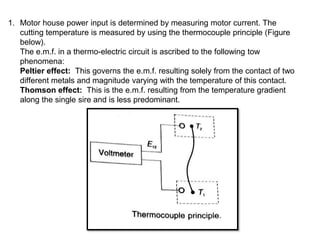

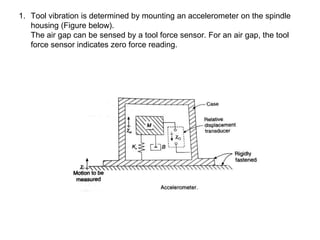

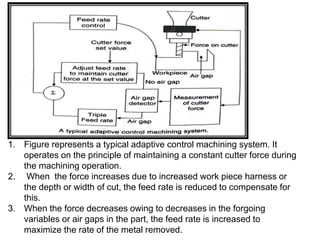

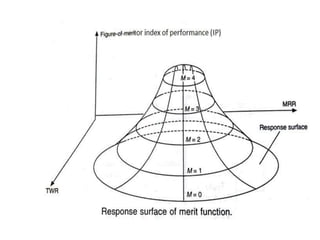

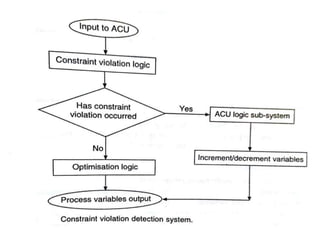

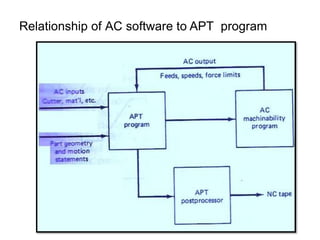

Adaptive control machining systems enhance machining efficiency by measuring various process variables such as spindle deflection, torque, and cutting temperature to optimize speed and feed. These systems significantly reduce non-productive time during machining operations, leading to increased metal removal rates and decreased costs. Adaptive control can be classified into optimization and constraint types, aimed at improving production rates while preventing process variable violations.