The document discusses process planning methods, including manual and computer-aided process planning. It covers the following key points:

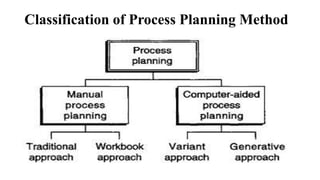

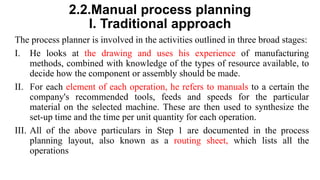

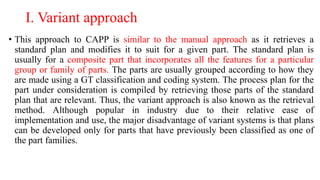

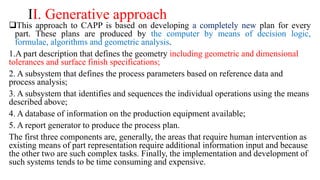

Manual process planning can involve traditional or workbook approaches. The traditional approach relies on a planner's experience to determine operations, while the workbook approach uses pre-determined sequences. Computer-aided process planning can be variant or generative. Variant CAPP retrieves standard plans, while generative CAPP develops new plans using decision logic.

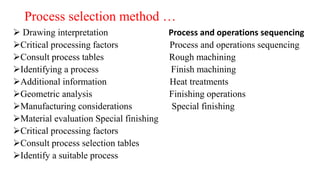

Factors like part dimensions, tolerances, and material selection influence the choice of manufacturing processes. Process selection considers part details from drawings and criteria like production quantities, costs, and quality needs. Both manual and computer-aided methods aim to efficiently sequence operations based