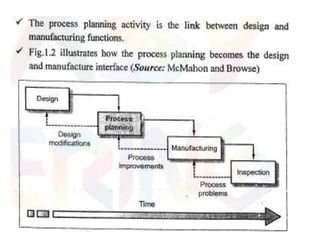

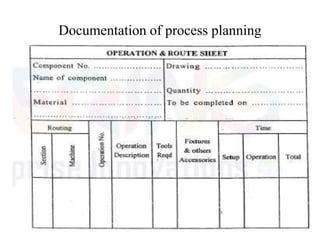

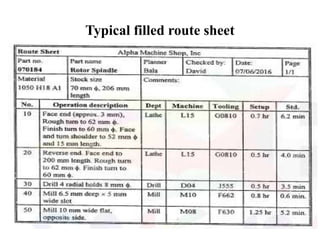

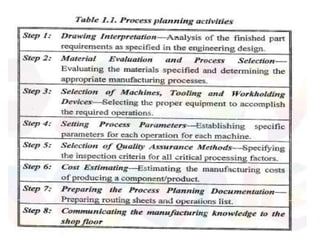

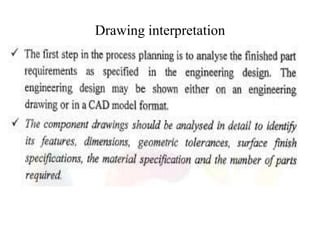

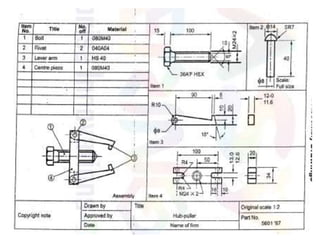

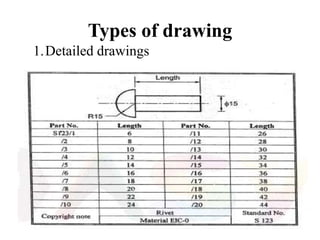

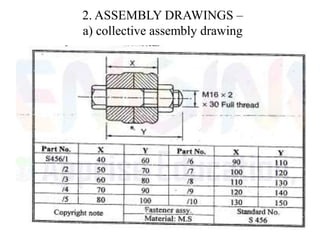

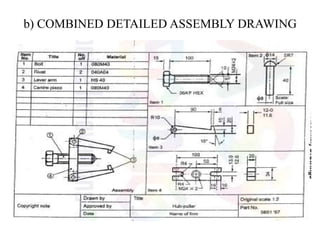

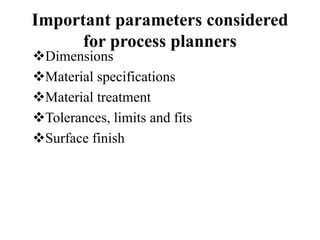

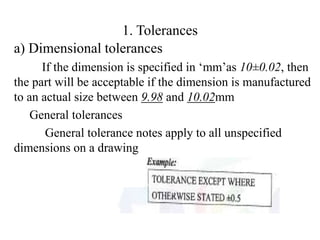

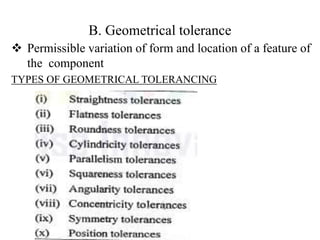

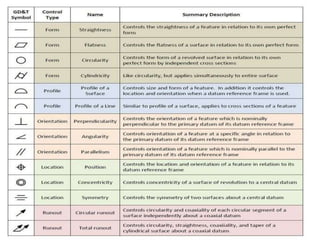

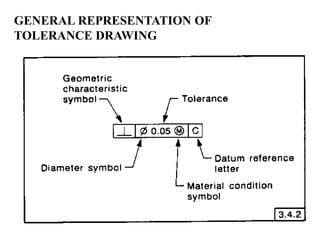

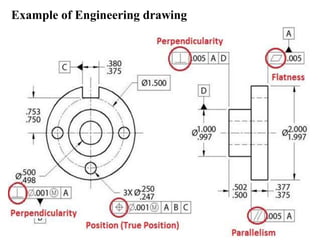

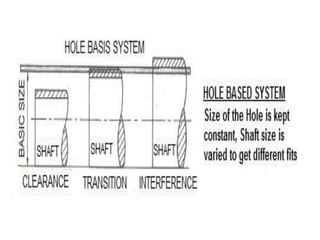

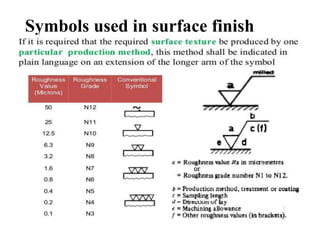

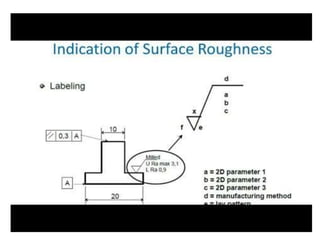

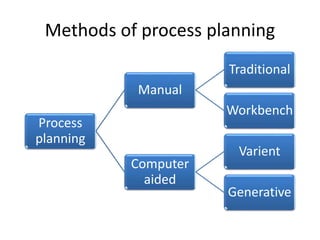

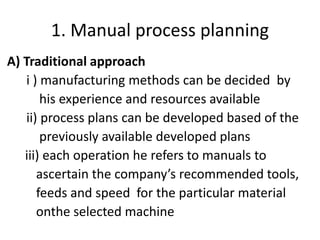

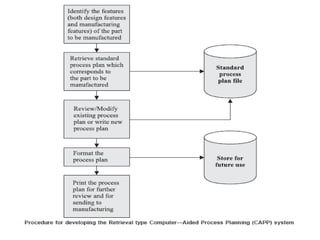

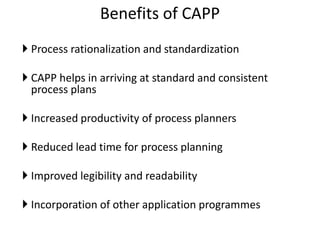

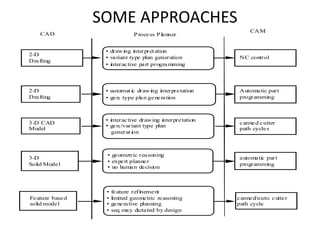

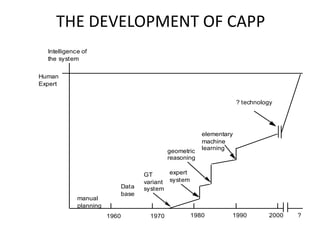

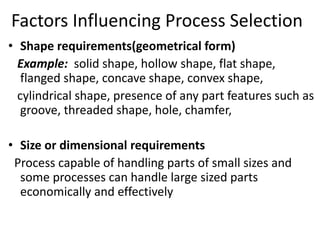

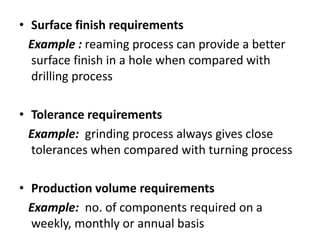

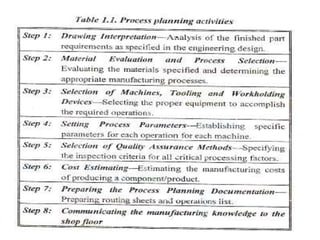

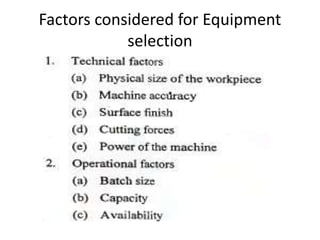

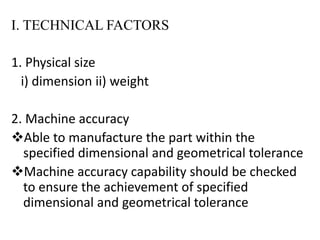

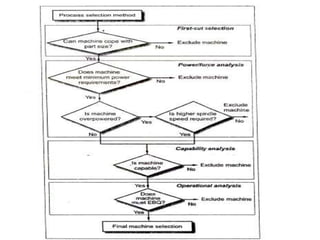

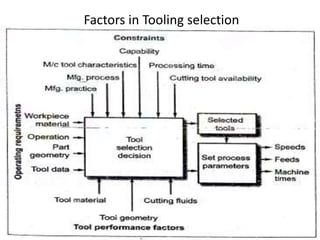

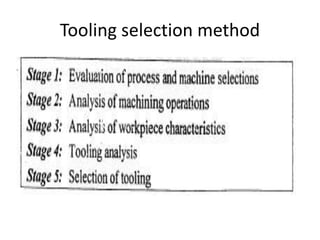

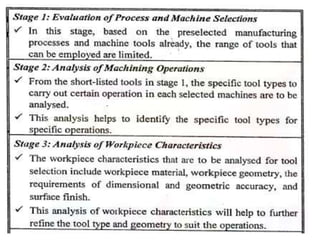

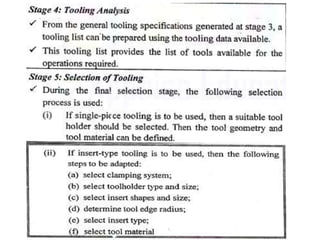

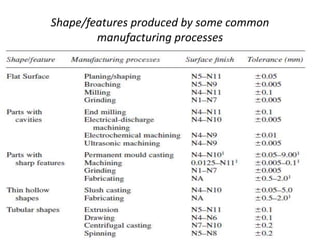

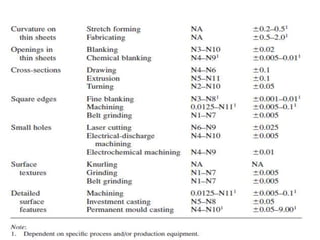

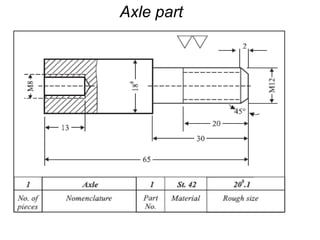

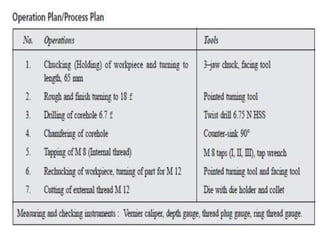

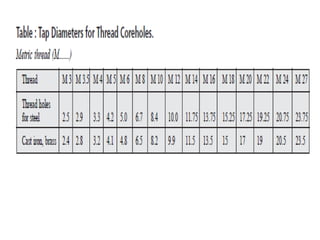

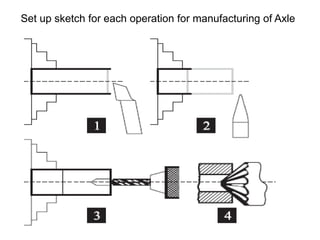

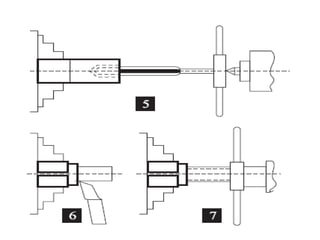

The document discusses process planning which involves preparing instructions for manufacturing a product. It establishes the link between design and manufacturing. Key steps in process planning include drawing interpretation, determining operations, tools, equipment and sequence. Factors considered are dimensions, tolerances, material, surface finish. Process planning is done manually using workbooks or through computer-aided process planning for consistency and reduced time. Process, material and equipment selection factors are also outlined.