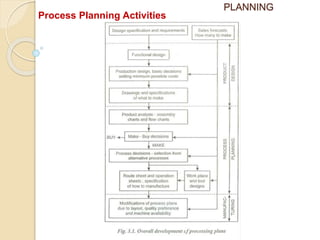

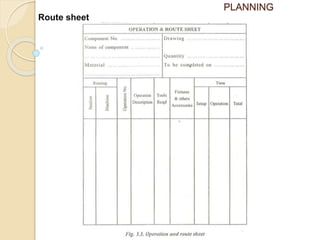

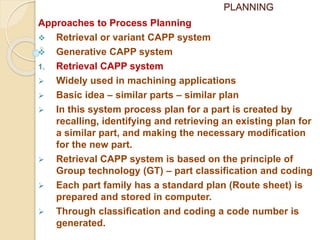

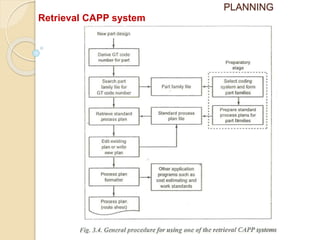

The document discusses process planning, which involves determining the manufacturing operations needed to transform raw materials into a finished product according to the product design and specifications. Process planning consists of selecting machining processes and equipment, determining the sequence of operations, and documenting the plan. It aims to manufacture the product completely and economically. The key aspects covered are the importance of process planning, requirements of a good plan, approaches to process planning including manual and computer-aided methods, and the typical activities involved like analyzing part requirements, selecting machines and processes, and calculating processing times.