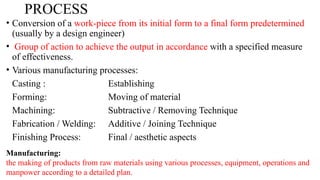

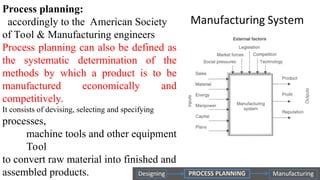

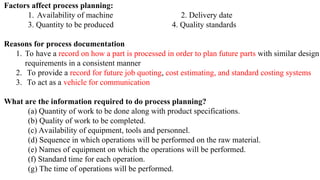

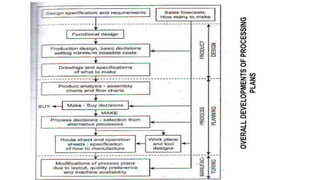

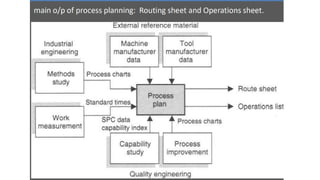

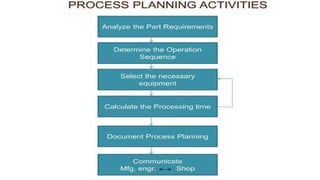

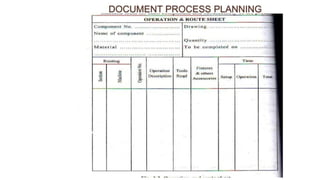

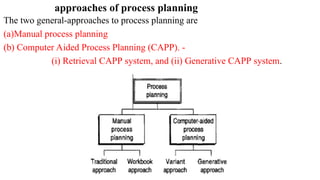

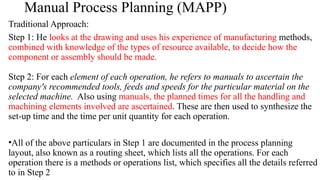

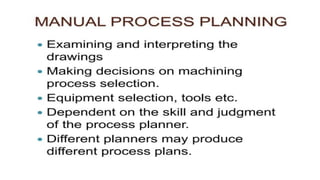

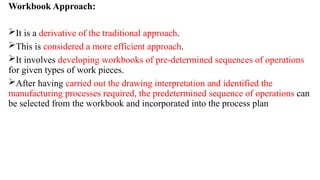

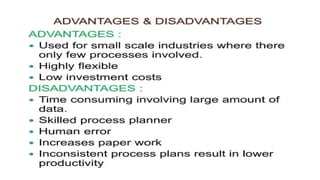

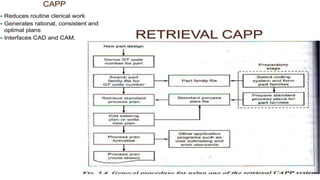

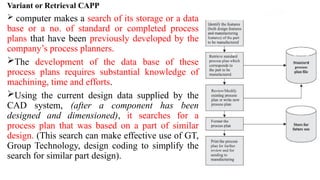

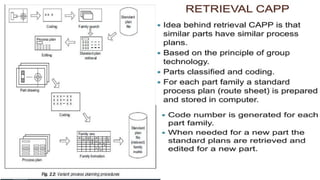

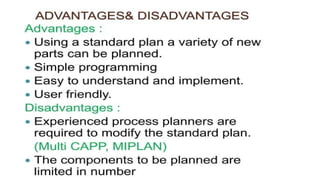

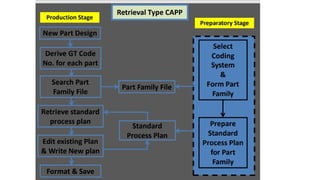

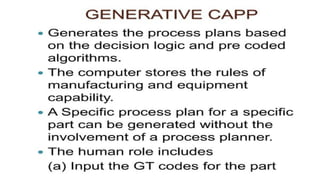

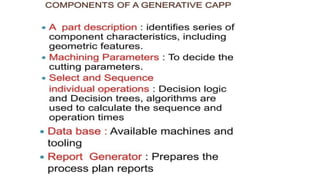

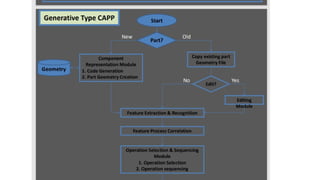

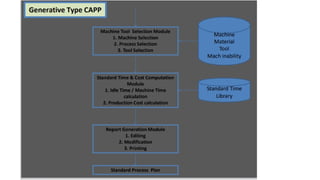

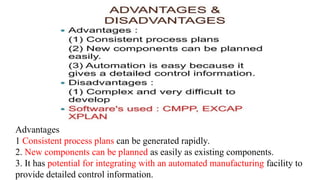

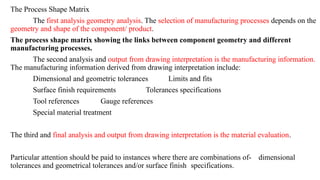

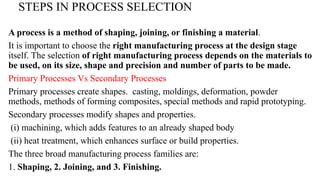

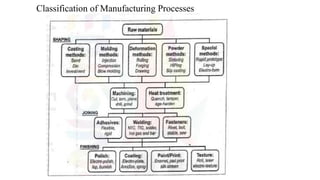

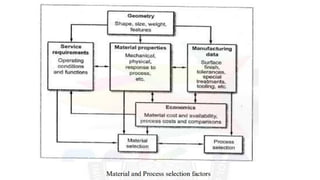

The document outlines the process planning methods in manufacturing, detailing drawing interpretation, material evaluation, and equipment selection. It describes manual and computer-aided process planning (CAPP) approaches, emphasizing the importance of selecting appropriate manufacturing processes based on various factors, including geometry, materials, and economic considerations. Additionally, it covers the significance of process documentation and the selection of jigs and fixtures to enhance efficiency and reduce costs in production.