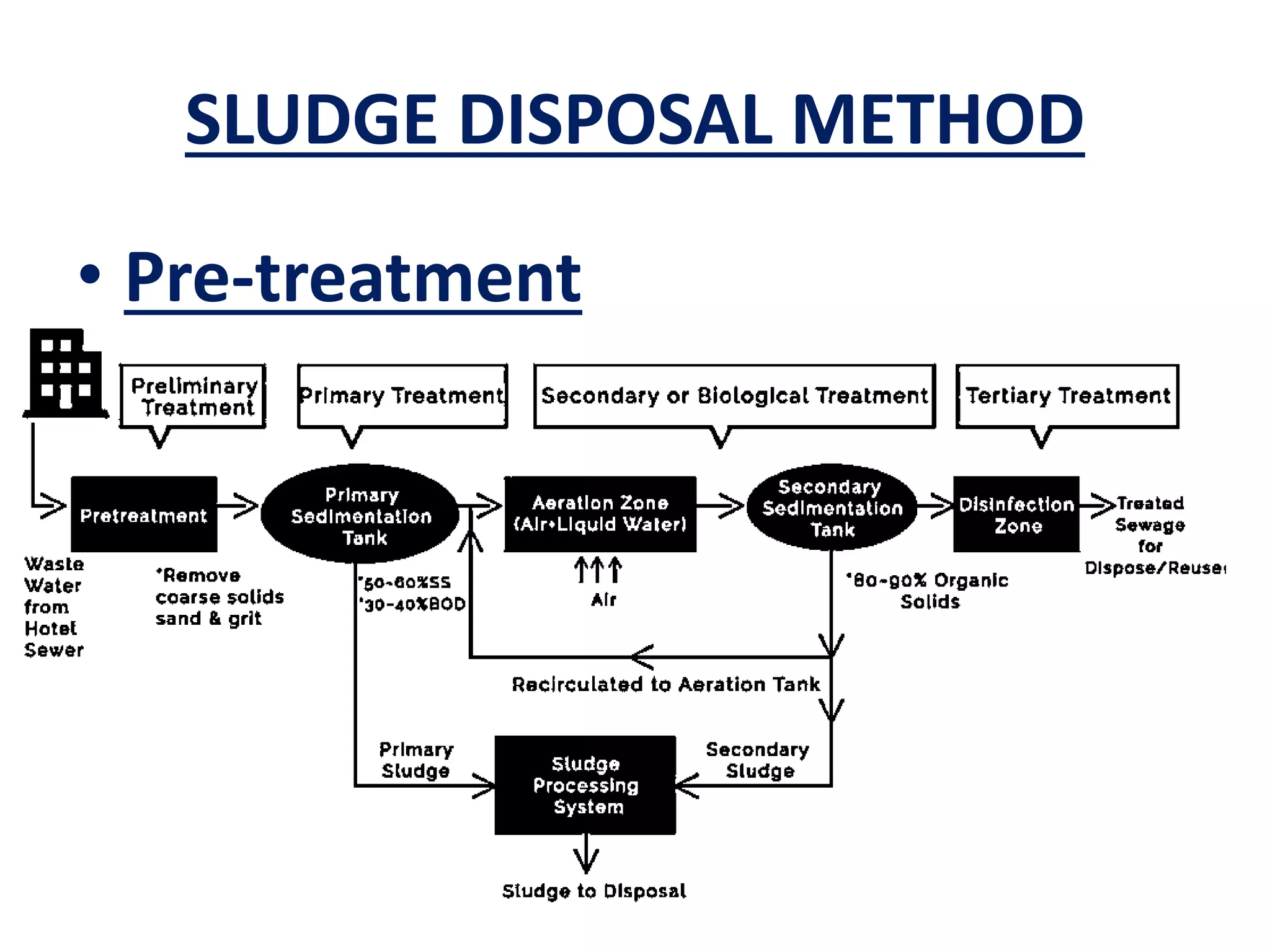

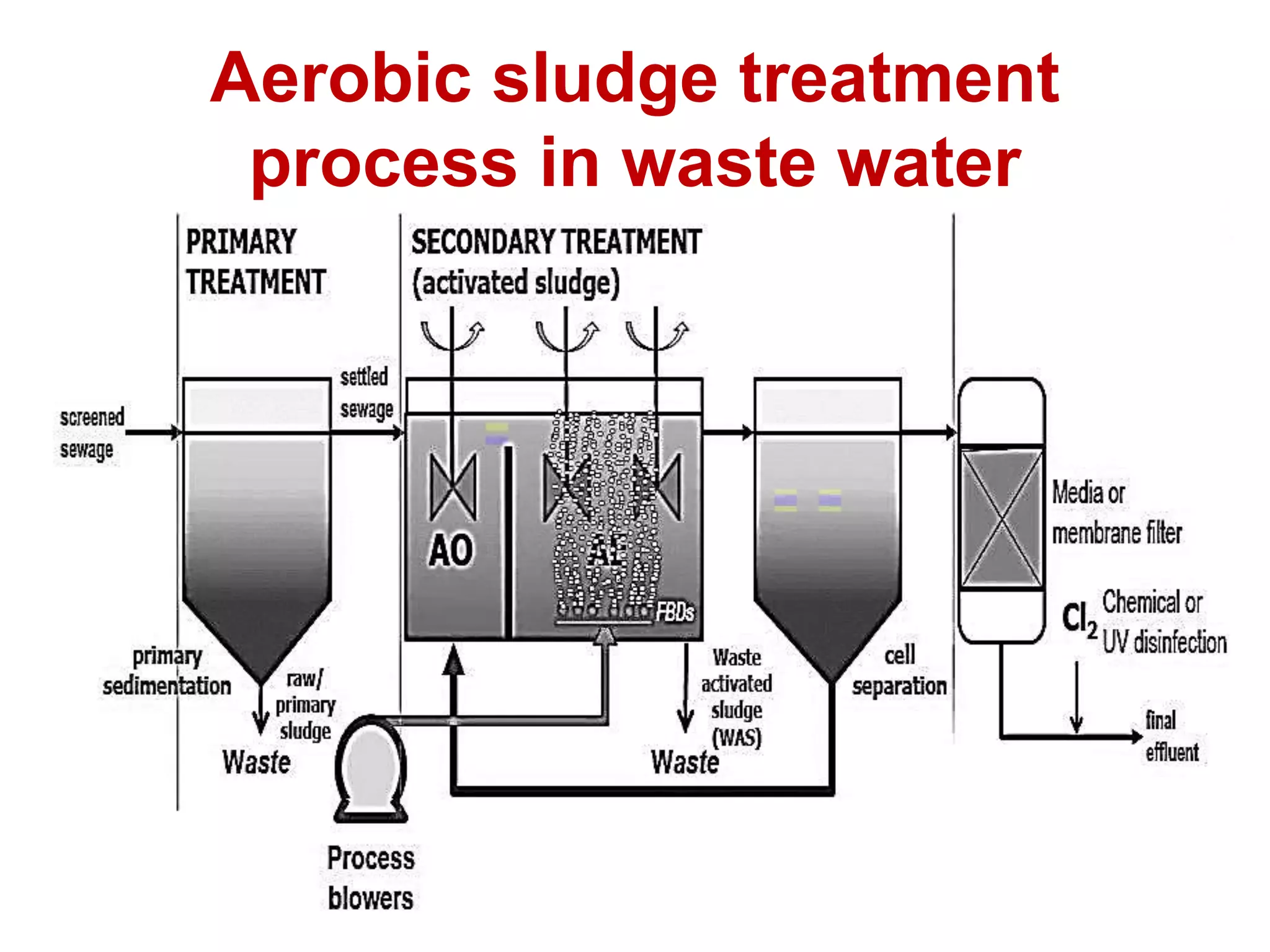

The document discusses various aspects of sludge treatment and disposal from wastewater treatment processes, categorizing sludge into primary, secondary, and tertiary types based on their production methods. It outlines treatment objectives to reduce moisture, remove organics, destroy microorganisms, and eliminate toxins, along with various methods such as anaerobic and aerobic digestion, gravity thickening, and belt filtering for dewatering. Additionally, it examines disposal methods including burial, use as fertilizer, and utilization in landfills, emphasizing the importance of effective sludge management to mitigate odor and environmental impacts.