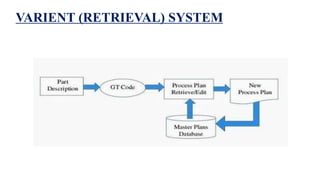

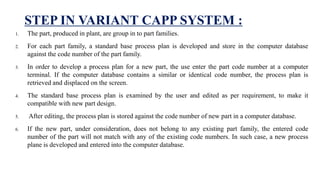

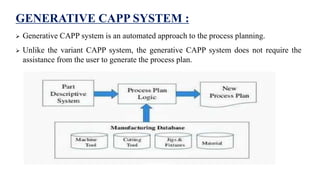

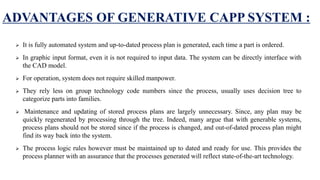

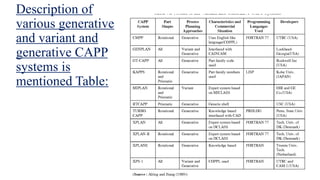

The document discusses Computer-Aided Process Planning (CAPP) as a system that selects and modifies process plans for manufacturing parts, focusing on three types: variant, generative, and hybrid systems. The variant CAPP system retrieves existing plans while the generative CAPP system automates the plan creation using algorithms, making it more efficient but requiring significant hardware investment. The hybrid CAPP system combines features of both approaches to enhance flexibility and efficiency in process planning.