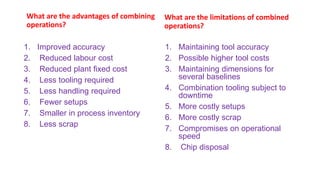

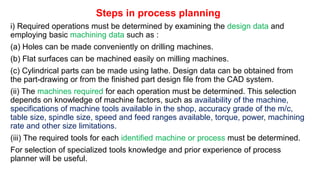

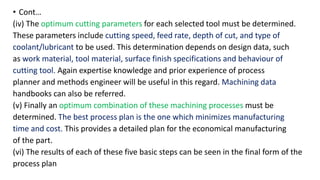

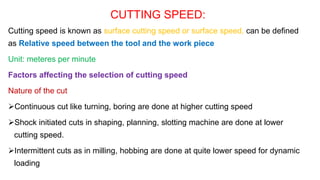

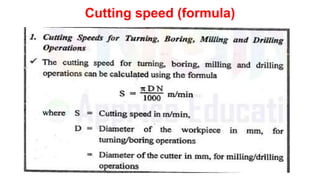

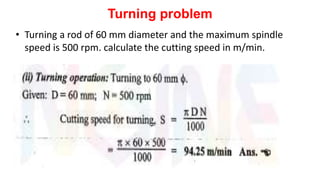

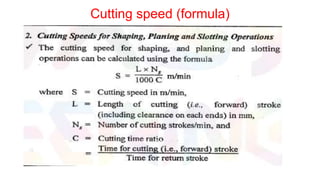

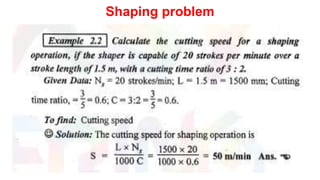

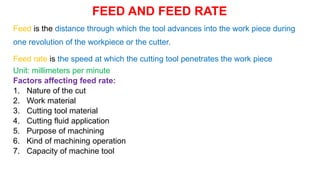

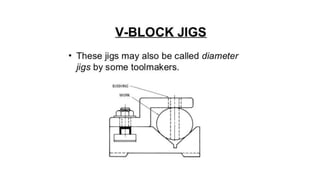

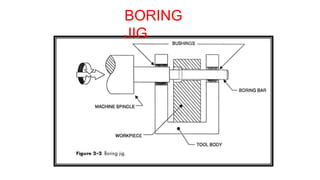

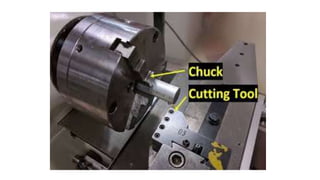

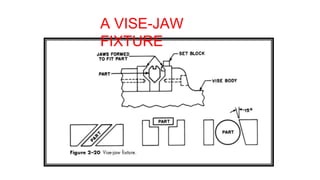

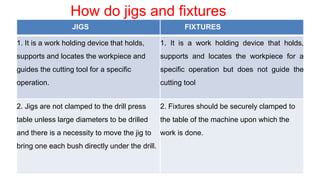

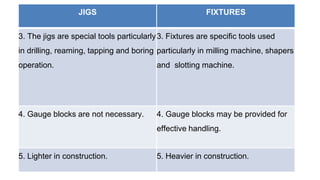

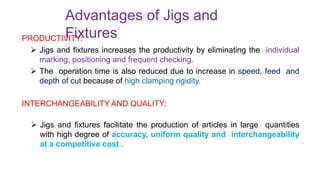

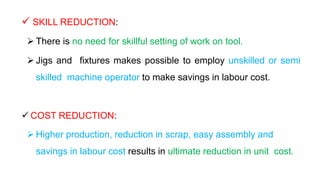

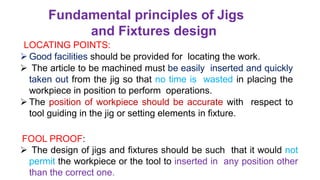

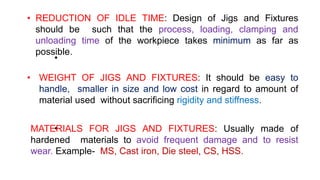

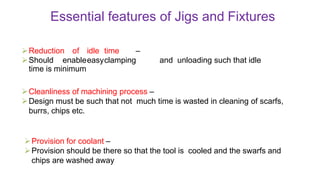

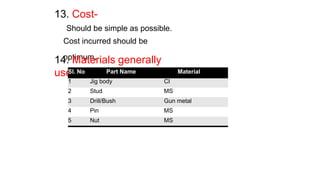

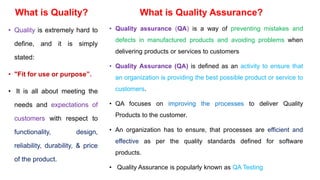

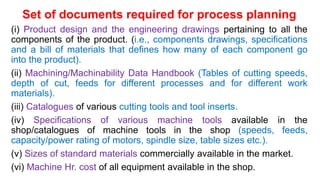

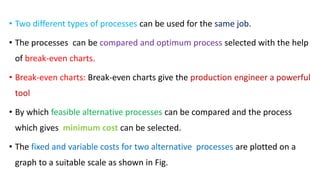

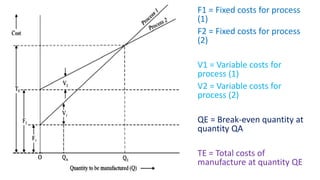

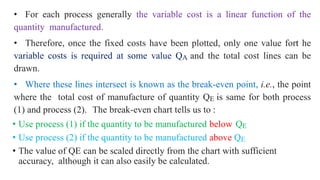

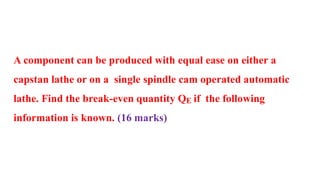

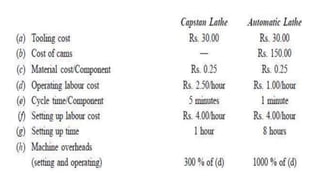

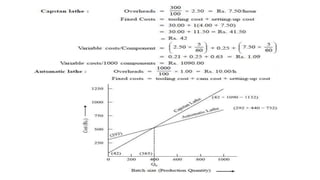

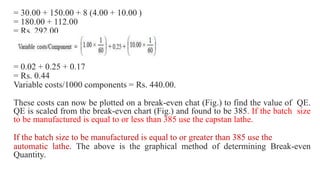

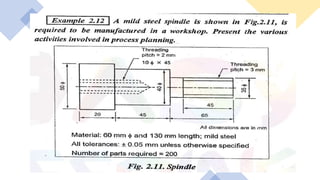

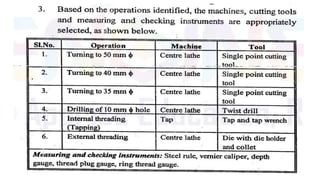

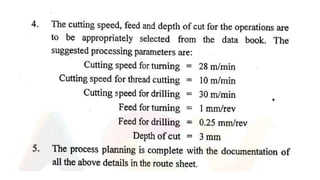

Unit 2 of the document focuses on process planning activities including process parameters calculation, selection of jigs and fixtures, and quality assurance methods. It discusses the importance of cutting speed, feed rate, and depth of cut in production processes, as well as the roles and differences between jigs and fixtures in enhancing production efficiency and quality. Key factors for effective process planning are outlined, emphasizing the need for economic considerations, tool performance, and operational accuracy.