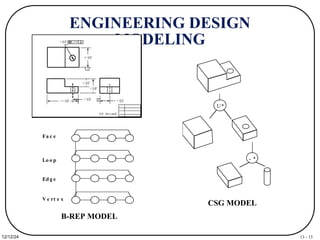

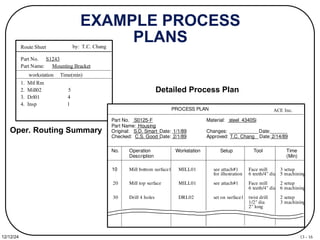

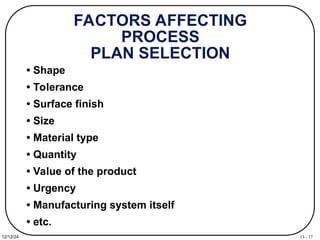

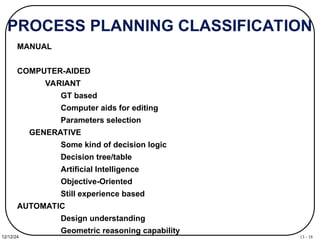

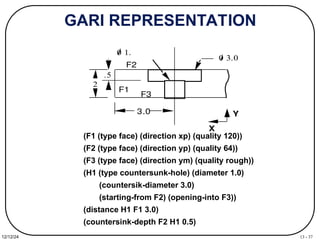

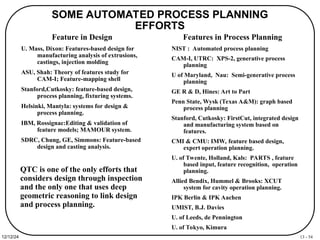

The document provides an overview of process engineering in manufacturing, focusing on process planning, operation programming, and the challenges faced by the industry, such as low utilization of programmable machine tools. It discusses different process planning approaches, including manual and computer-aided methods, and highlights advantages of automated process planning in reducing costs and time. Additionally, the document emphasizes the significance of manufacturing features in design and the need for effective feature recognition and representation in process planning.