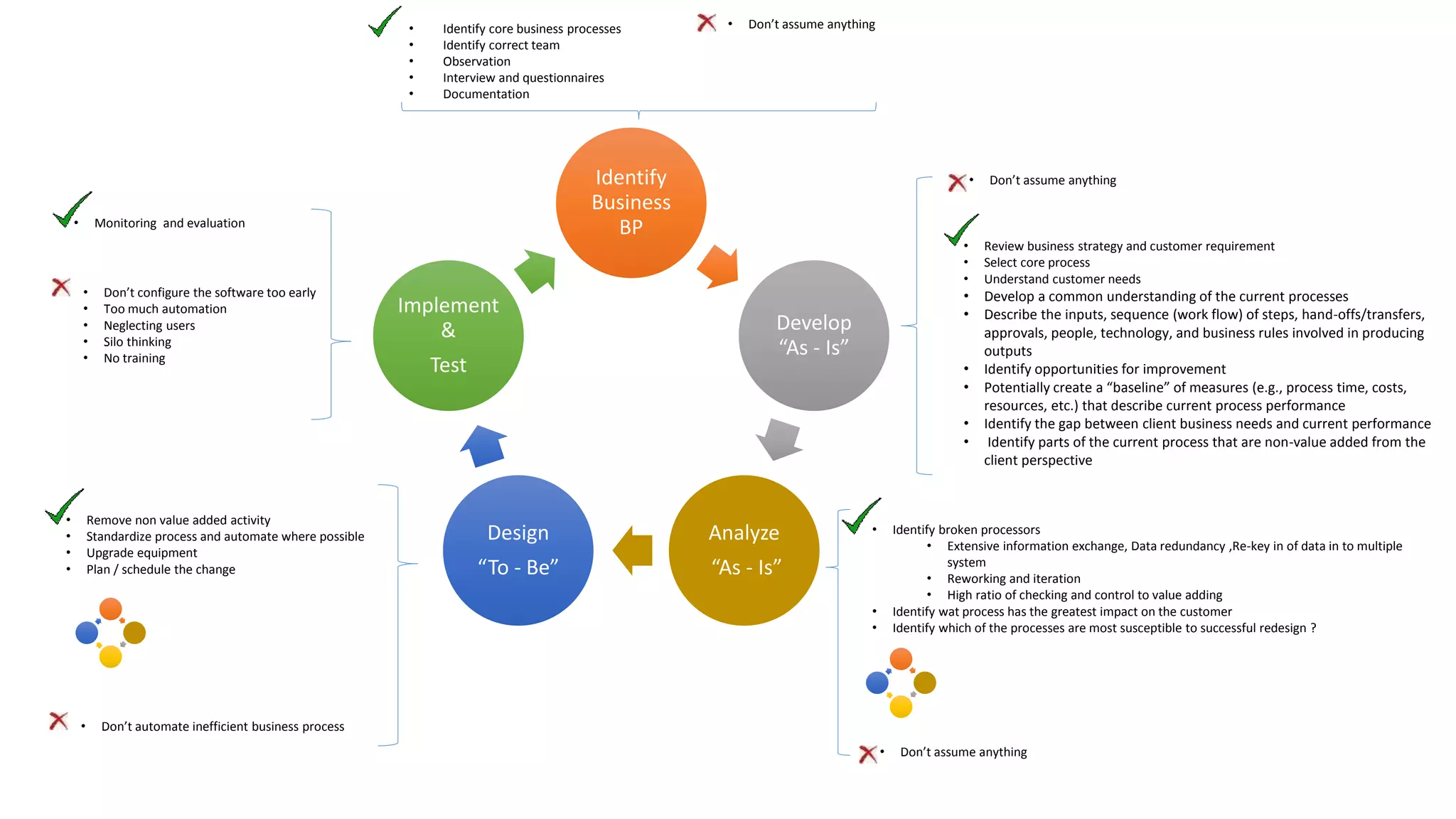

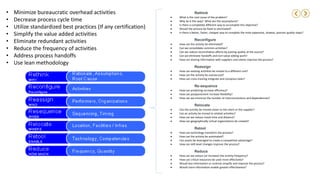

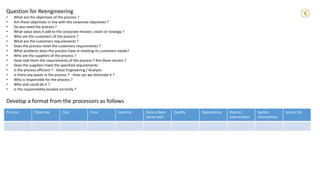

The document outlines the steps for business process reengineering which include identifying the as-is process, analyzing opportunities for improvement, designing an improved to-be process, implementing and testing the new design. Key activities involve understanding customer needs, mapping the current process, identifying non-value added activities, establishing performance metrics, addressing inefficiencies, and implementing and monitoring the new process. Questions to consider for reengineering include the objectives, customers, suppliers, efficiency, waste elimination, responsibilities, and whether the process is needed.