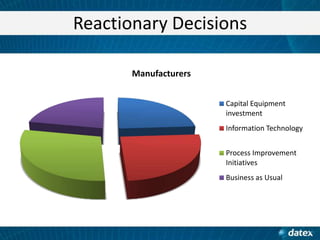

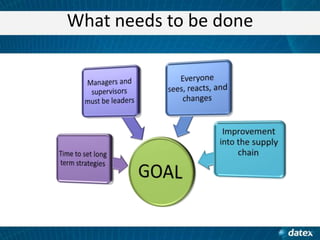

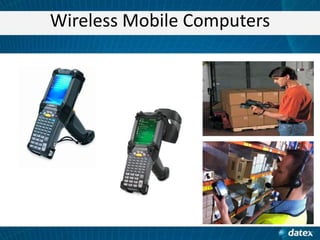

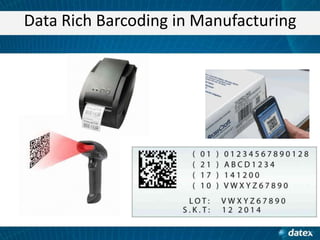

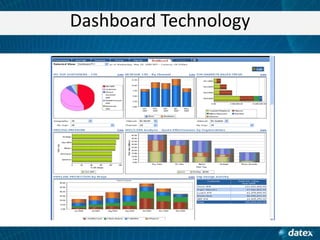

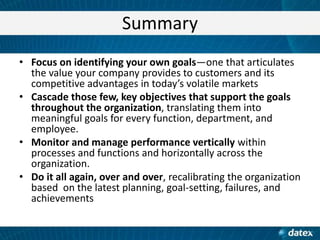

The document discusses approaches to implementing lean manufacturing through warehouse execution systems. It outlines some traditional approaches that fail, such as lack of management support and ineffective communication. Root causes of lean gaps are identified as reactionary decisions, uncertain workforces, shifting supply chains, and a lack of clear direction. The document recommends taking a lean approach through performance management to eliminate chaos and allow identification of problems and opportunities. Real-time information systems are also recommended to manage operations, customer demand, supply chains, workforces, and logistics. RFID, wireless mobile computers, barcoding, and dashboard technologies can help provide this real-time information. Overall, the key is to set goals and objectives and then continuously monitor and manage performance across the organization