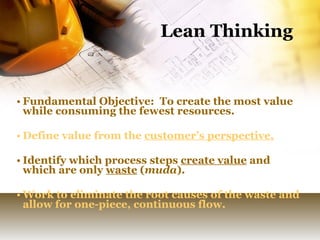

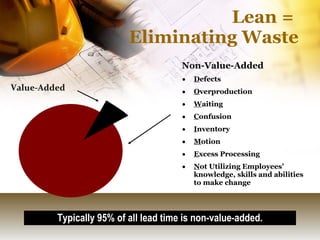

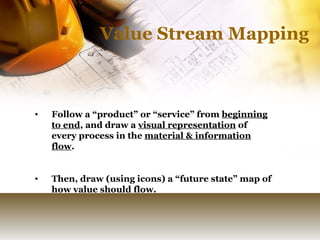

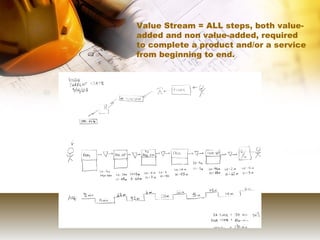

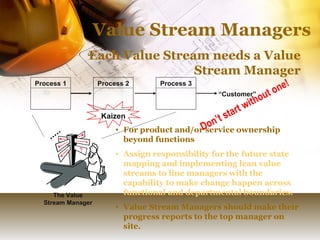

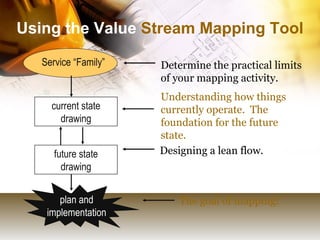

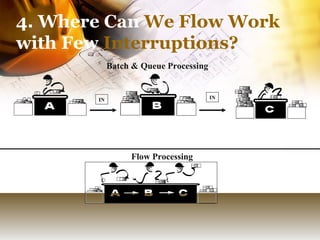

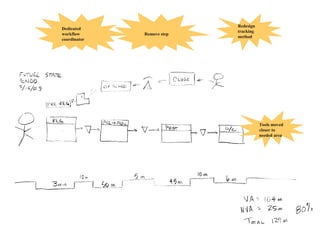

The document discusses lean thinking and value stream mapping. It defines lean thinking as focusing on eliminating waste to create the most value while using the fewest resources. Value stream mapping involves visually mapping the current and future states of a process from beginning to end. The future state aims to identify value-adding and non-value adding steps, eliminate waste, and allow for continuous flow. Key questions are asked to help design an improved future state, such as what the customer needs, how performance will be checked, and what process improvements are needed.

![Lean Thinking Travis Eck / Senior Business Process Analyst [email_address] 406-239-3773](https://image.slidesharecdn.com/leanthinking-100709094938-phpapp01/75/Lean-thinking-1-2048.jpg)