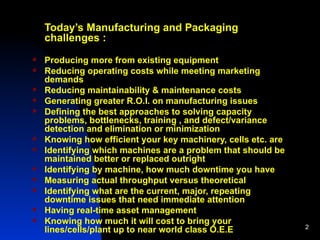

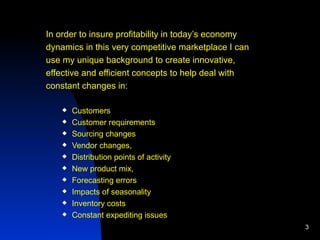

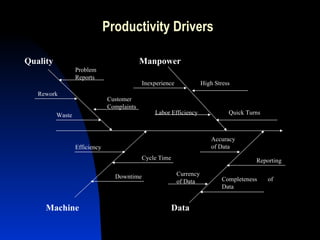

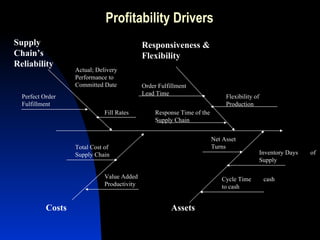

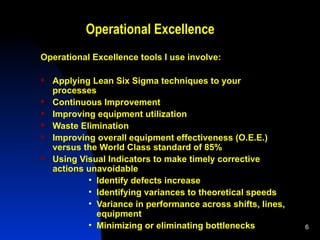

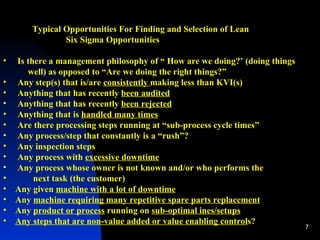

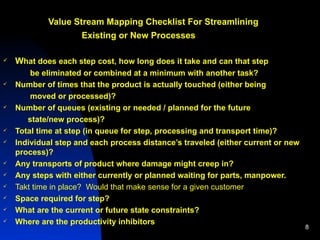

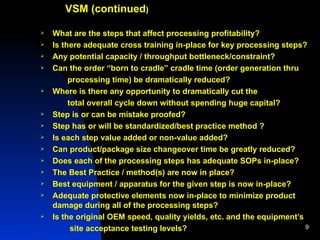

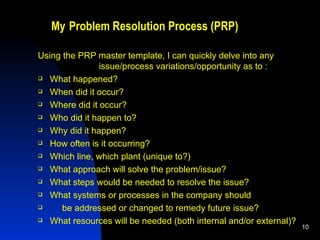

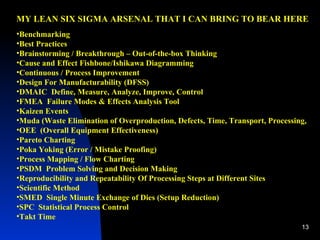

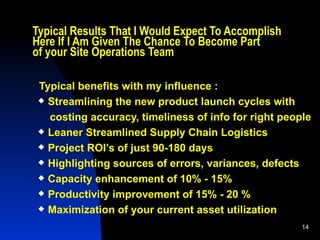

The document discusses opportunities for improving manufacturing and packaging operations through lean strategies like reducing waste, improving equipment effectiveness, and identifying sources of downtime. It outlines John Van Horn's approach and toolbox for conducting analyses to streamline processes, maximize throughput, ensure profitability, and achieve typical results such as enhanced capacity and productivity gains of 15-20%.