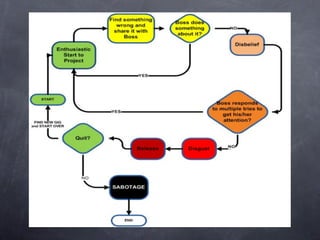

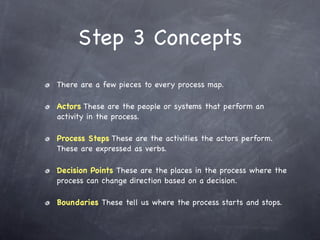

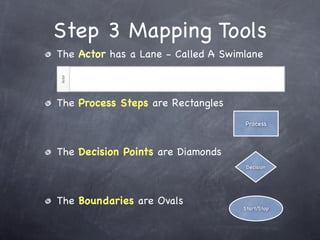

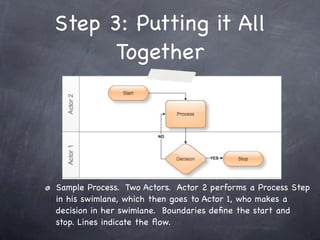

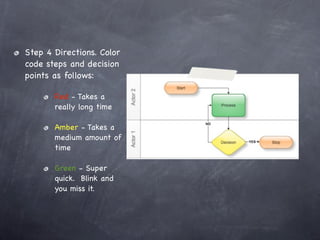

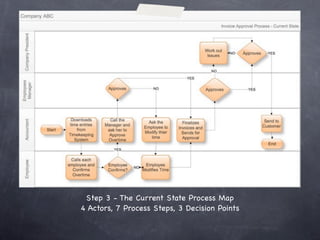

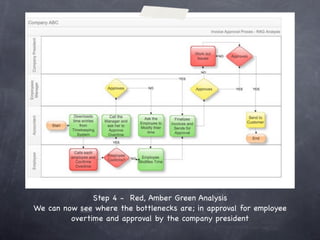

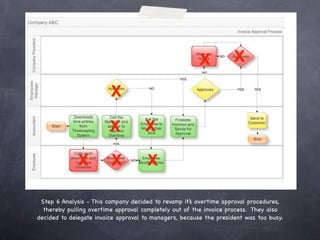

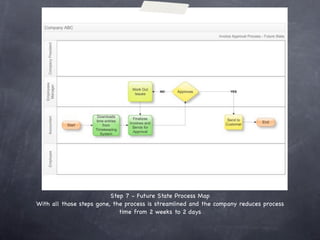

The document provides a concise guide for small business owners on how to implement process mapping for improving business efficiency. It outlines seven basic steps, from identifying current problems to visualizing goals and redesigning processes, all aimed at enhancing productivity and employee satisfaction. Key reasons for process improvement include reducing bottlenecks, fostering innovation, and improving customer satisfaction.