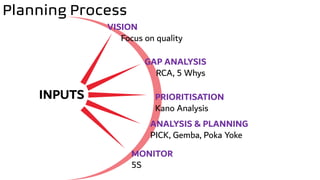

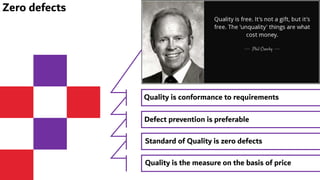

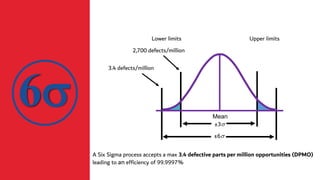

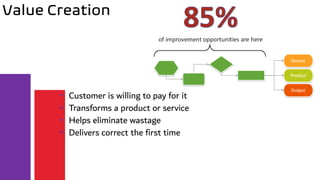

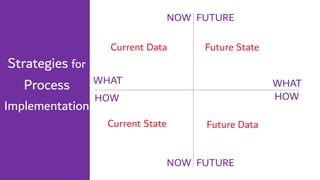

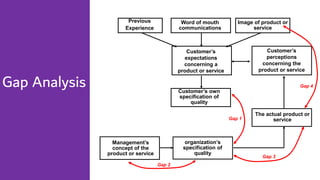

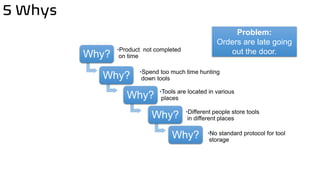

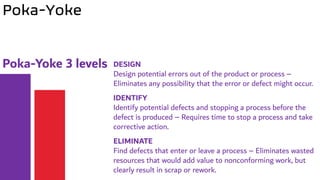

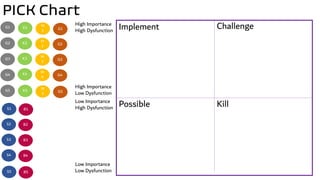

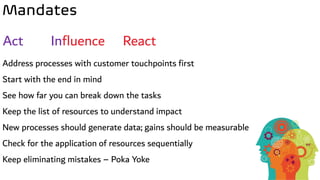

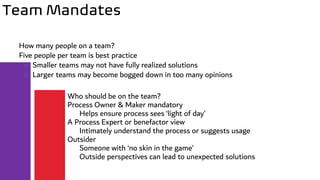

This document provides information on quality processes and process improvement strategies. It discusses concepts like the planning process with inputs like vision and gap analysis, prioritization using Kano analysis, and monitoring. Other sections cover quality definitions and strategies for competitive advantage like cost leadership, differentiation, and customer orientation. Process improvement frameworks like Lean, Six Sigma, TQM and BPR are mentioned. The document also includes information on benchmarking, value creation, implementation, and team mandates for process improvement projects.