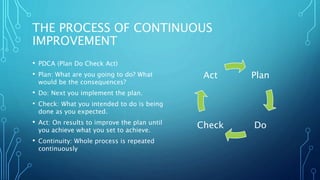

The document discusses the concept of the continuous improvement process, highlighting key areas of efficiency, such as waste reduction and process enhancement. It emphasizes the importance of observation, detailed recording, and analysis of actions to identify improvement opportunities. Additionally, it outlines various tools and methodologies like PDCA and Six Sigma to facilitate ongoing enhancement in organizational processes.