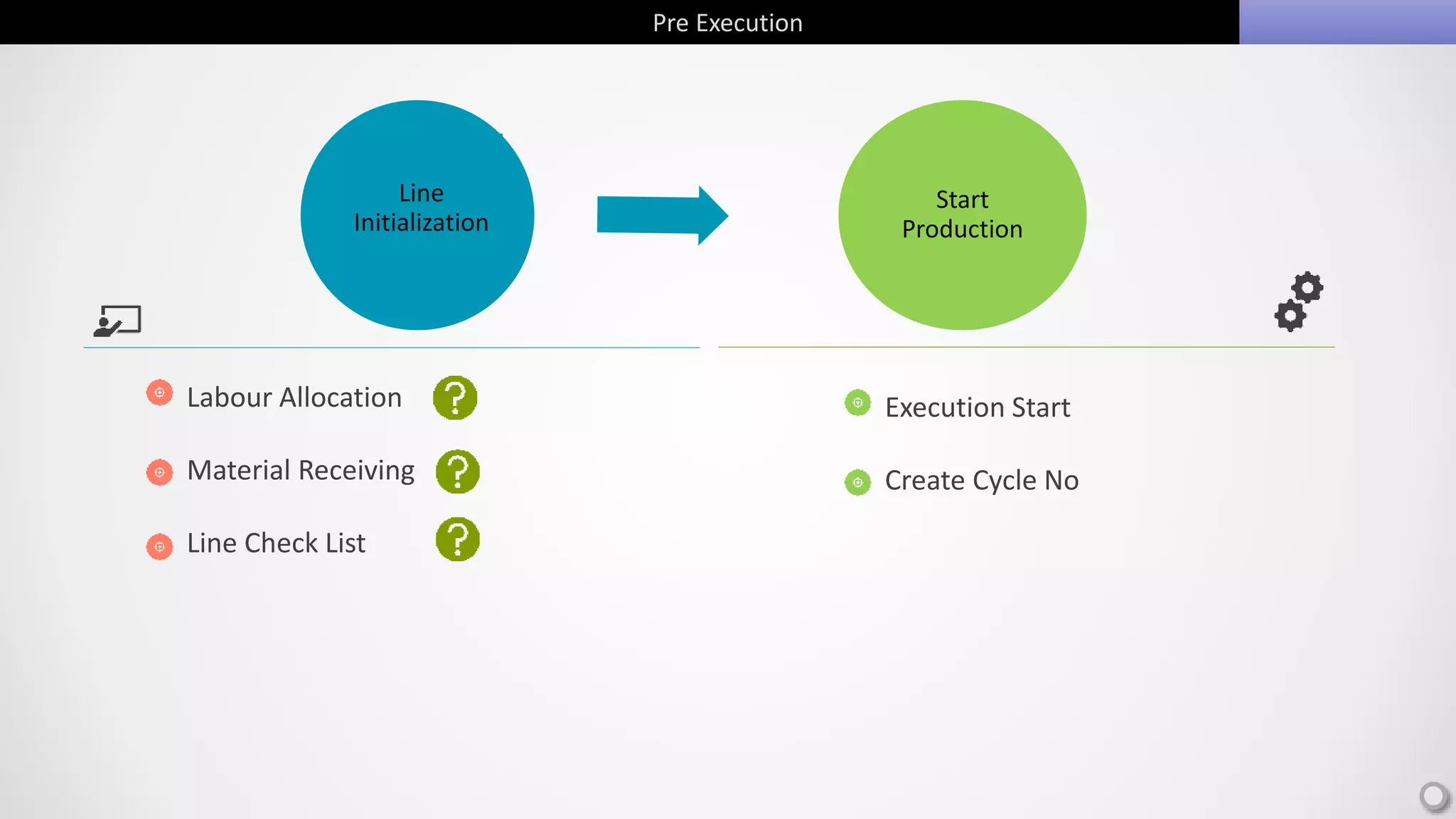

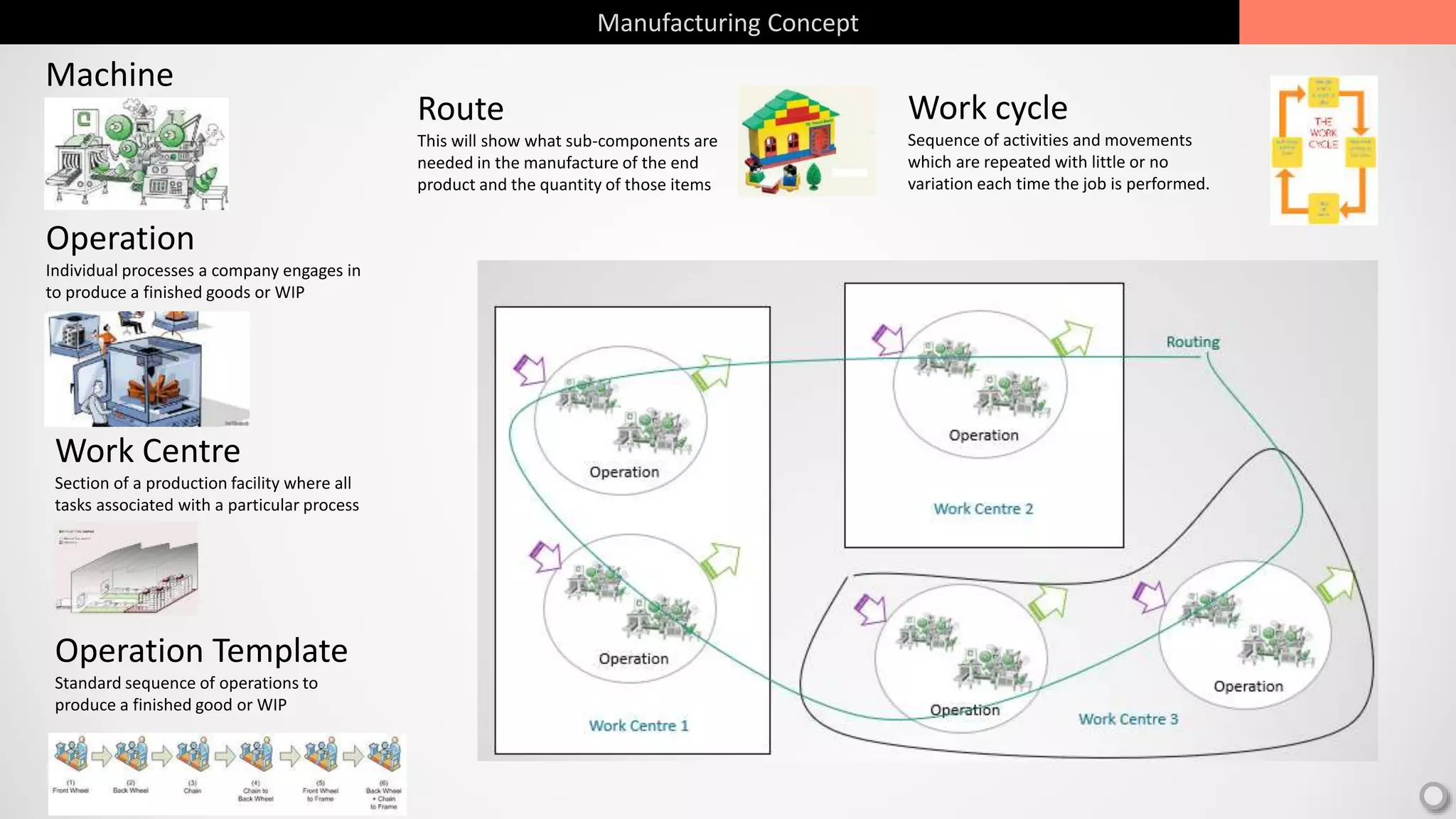

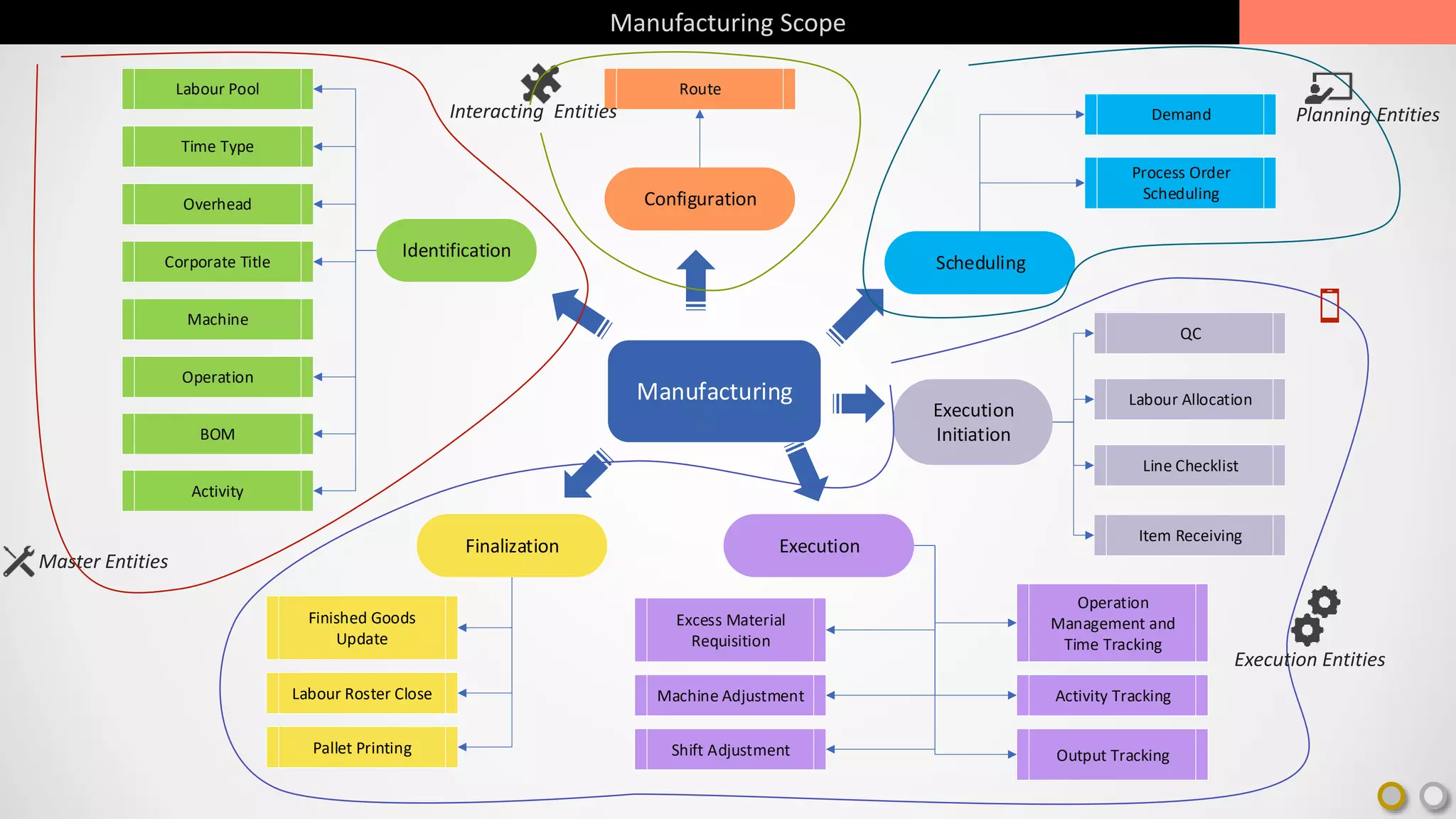

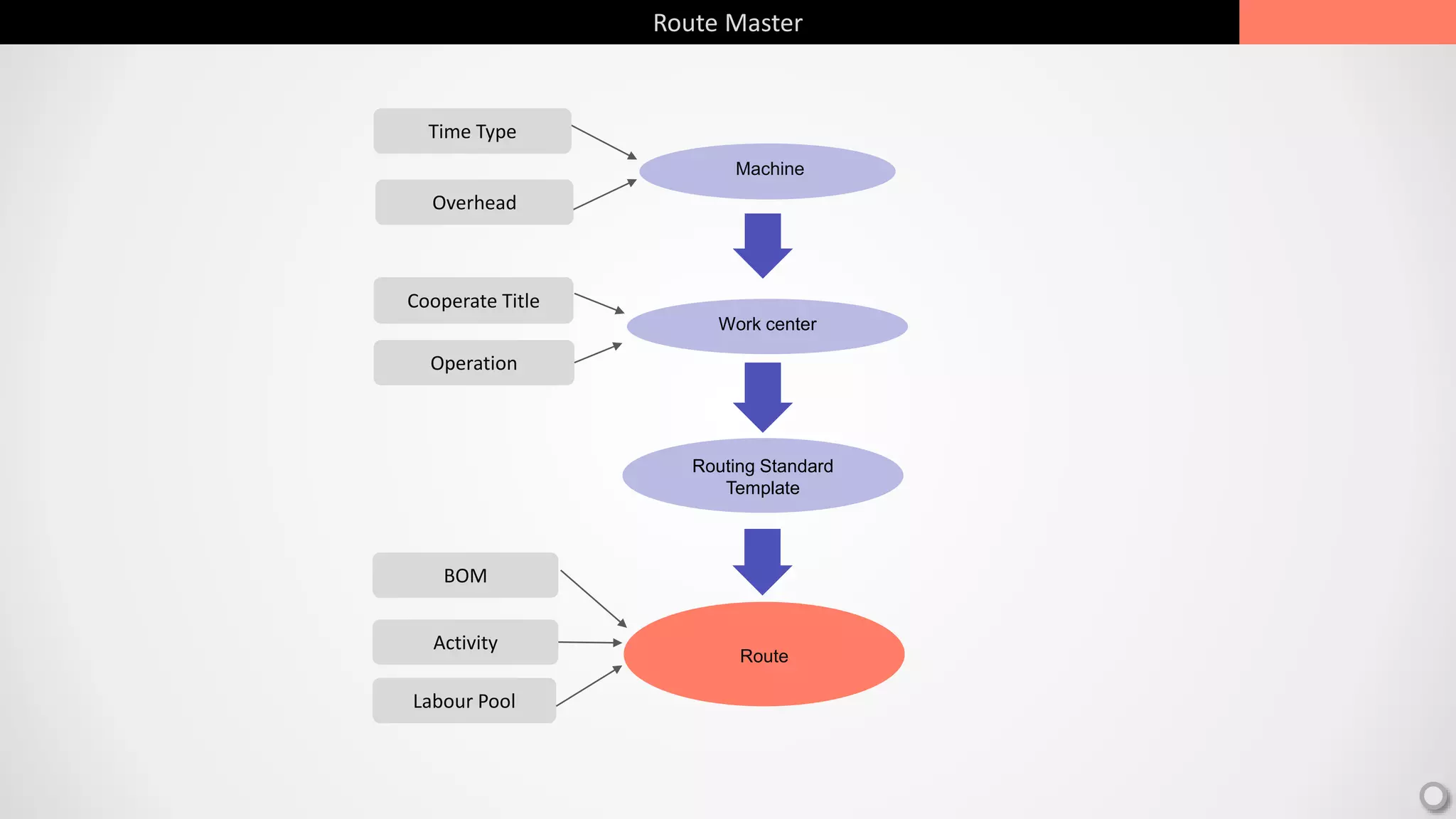

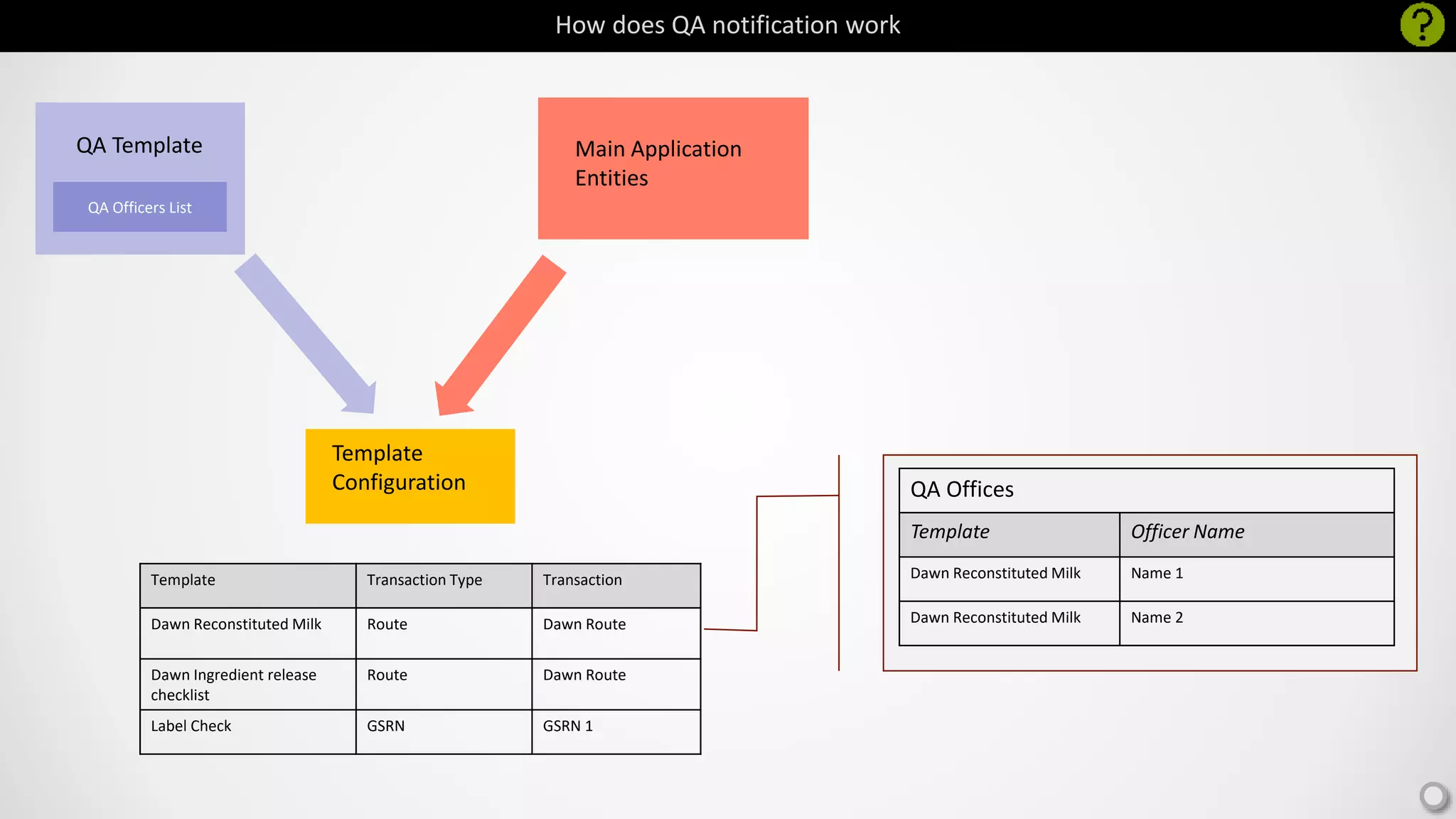

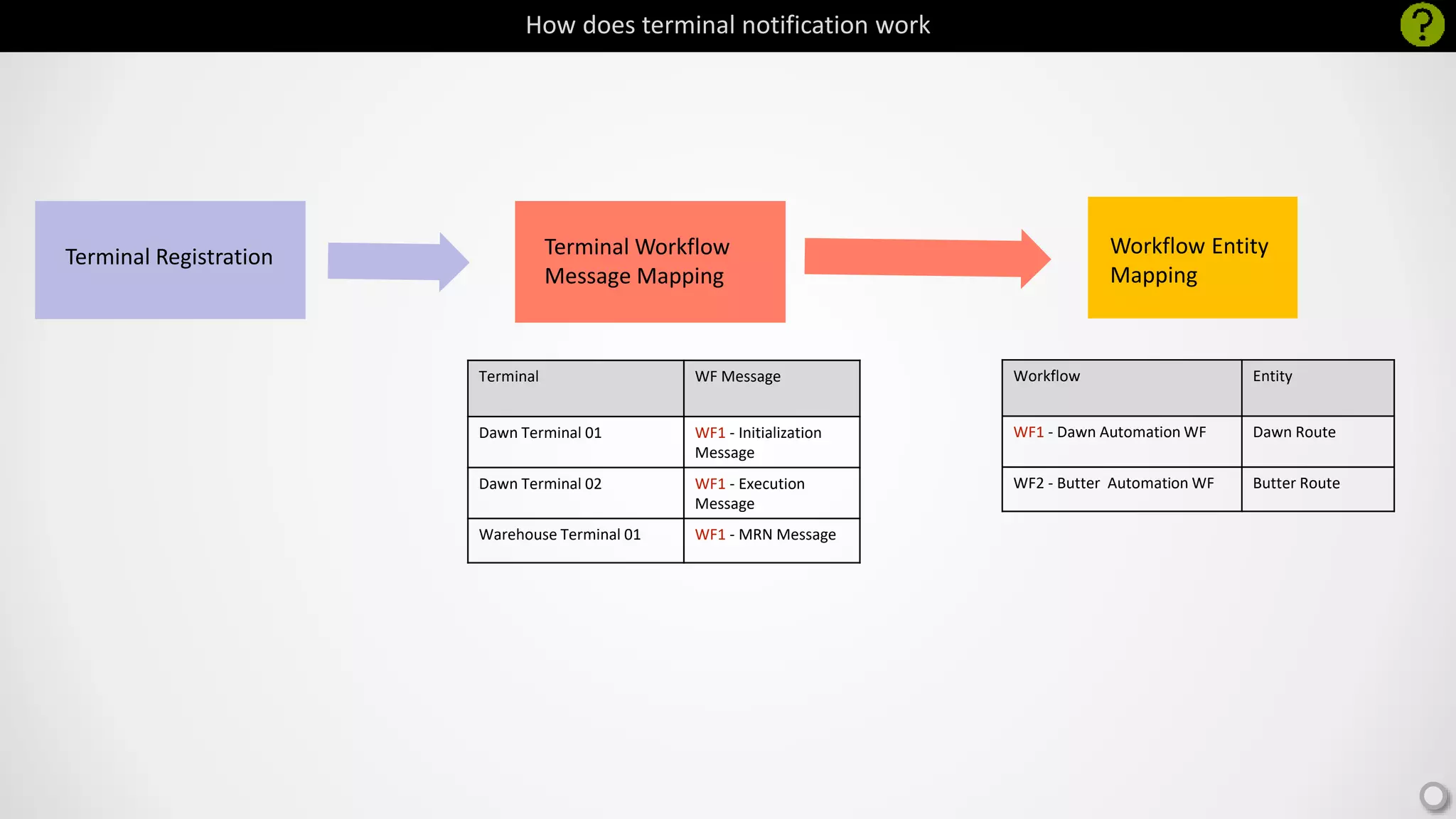

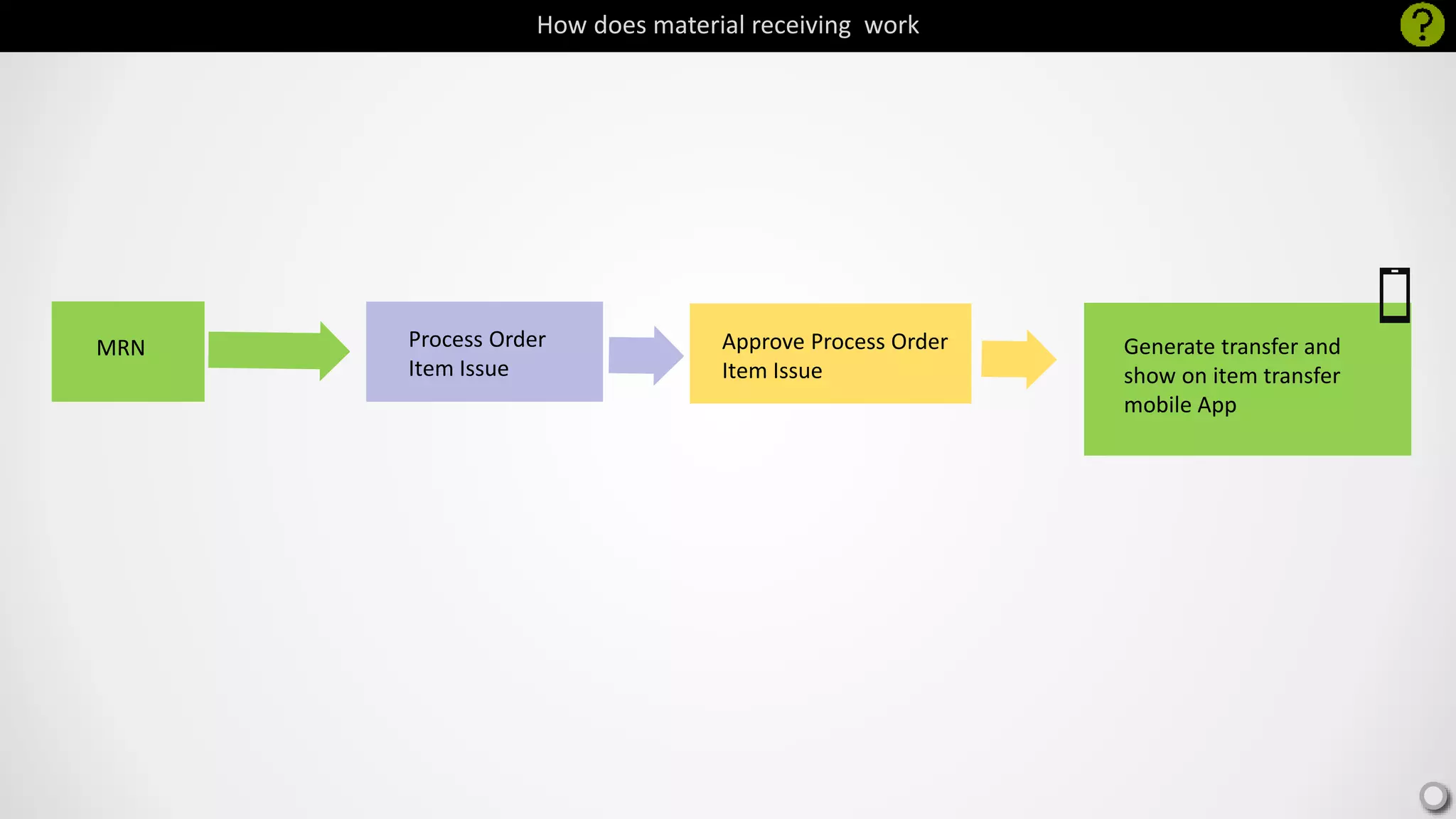

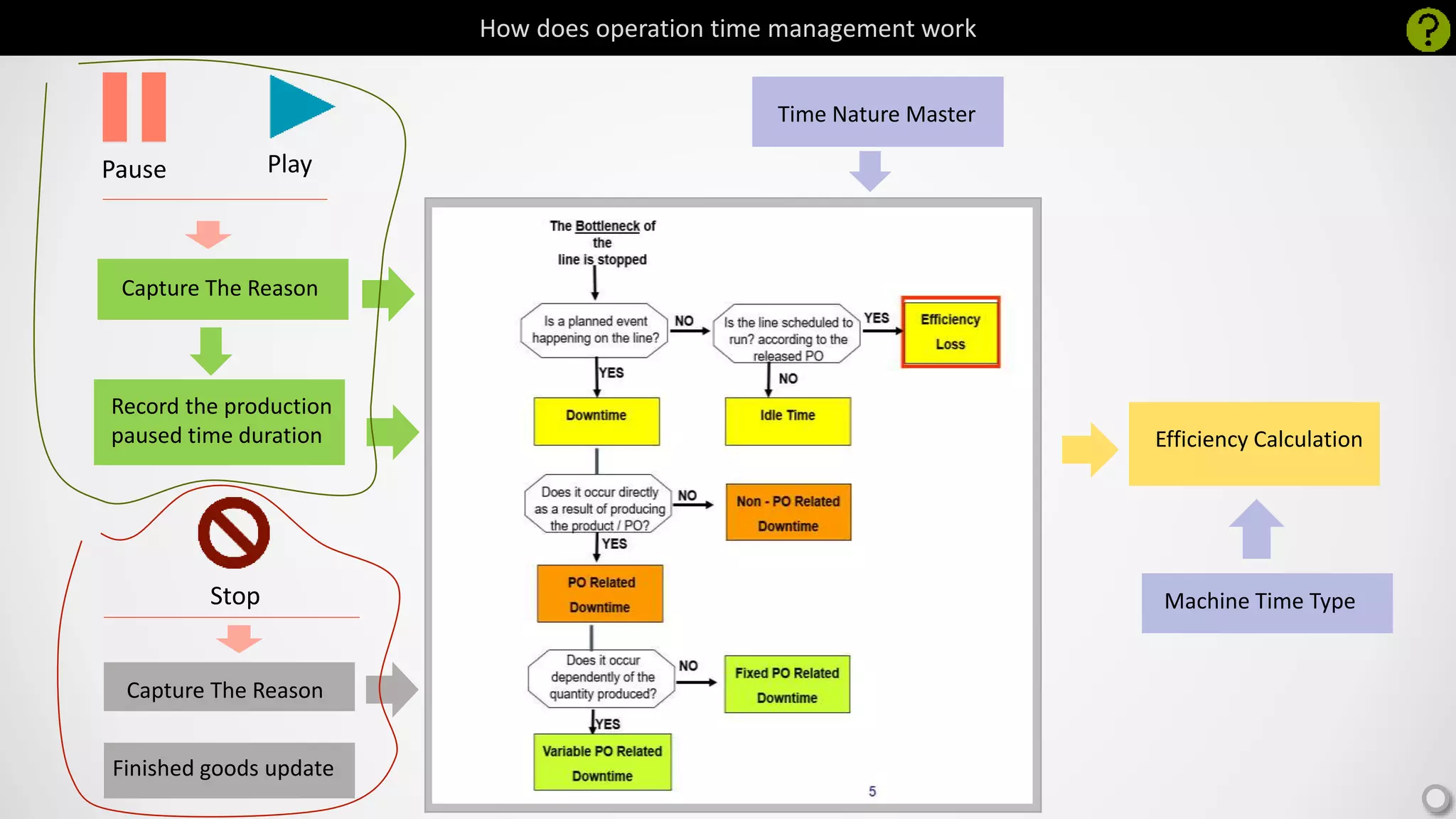

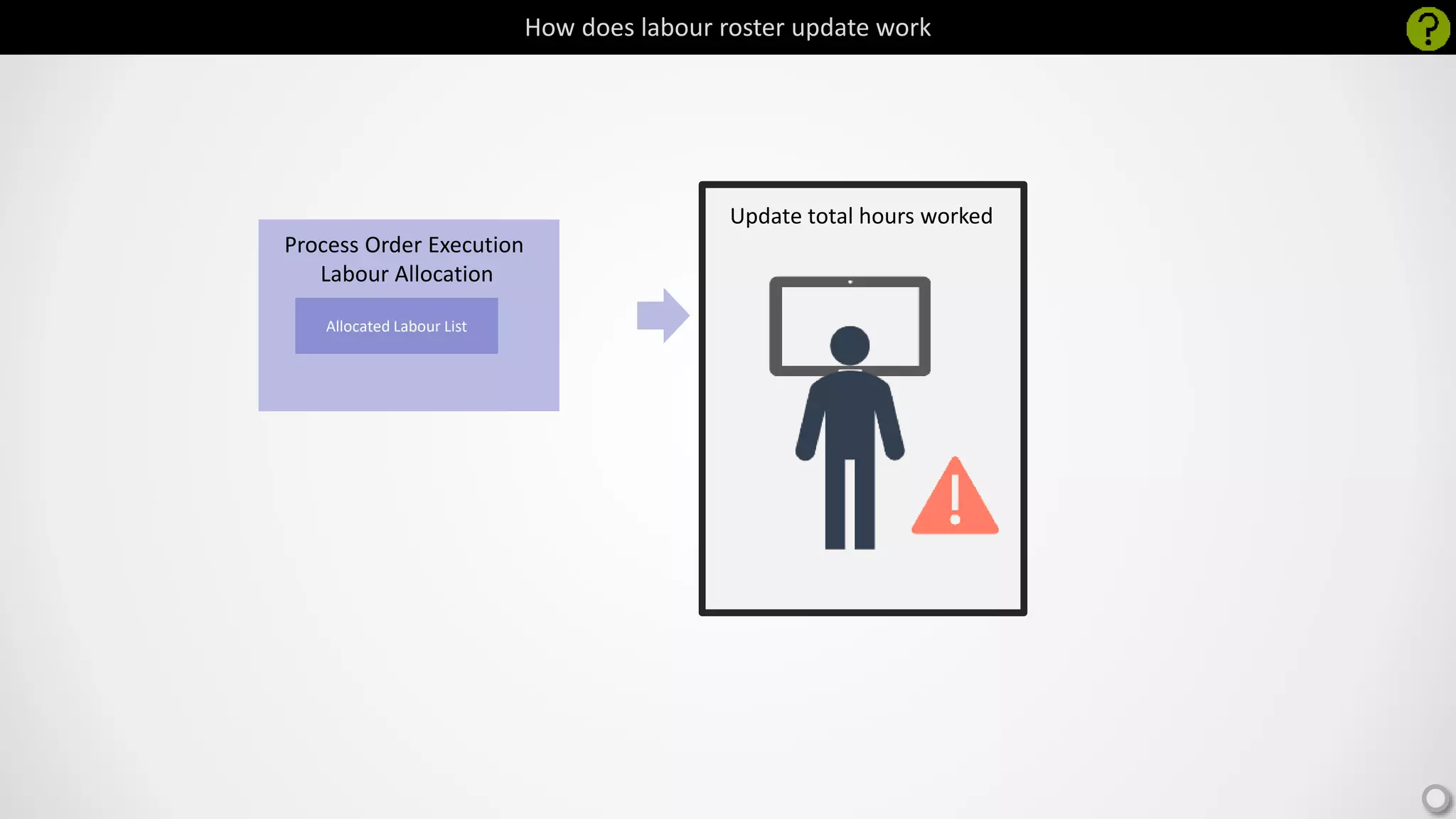

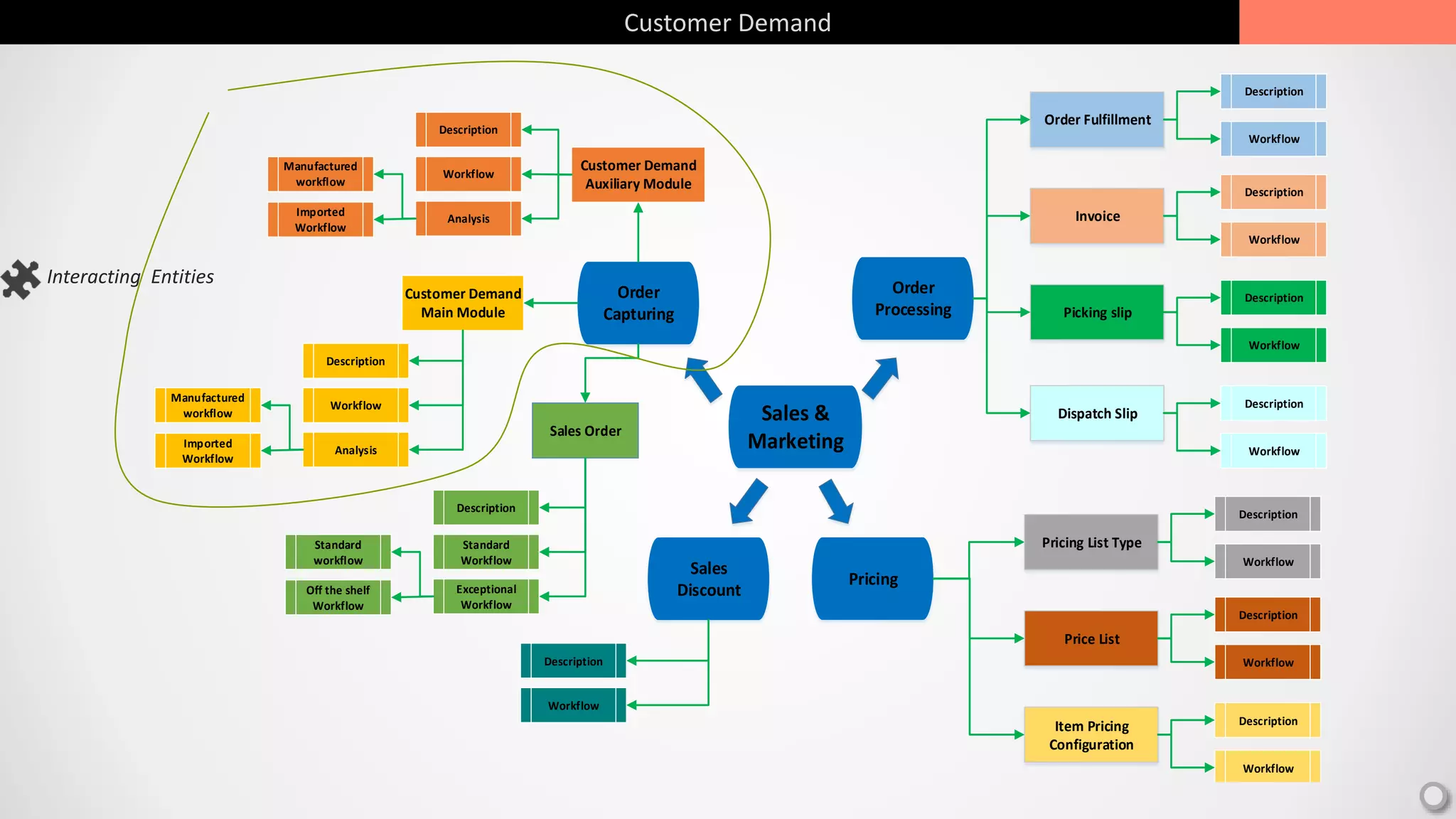

Bizzxe 2.0 is an ERP software that manages various functions like supply chain, sales and marketing, manufacturing, quality assurance, administration, and finance. It uses a main application and auxiliary applications to capture online and offline data and convert it into insights. It manages the entire manufacturing process from data setup to production planning, pre-execution, execution, and post-execution. Key functions include quality management, production planning, execution monitoring, quality control, item transfers, and updating production records.