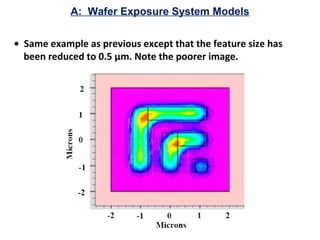

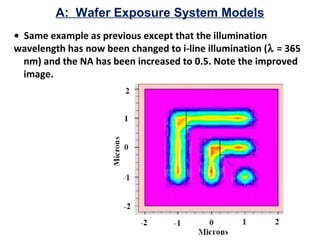

This document discusses various topics related to photolithography including:

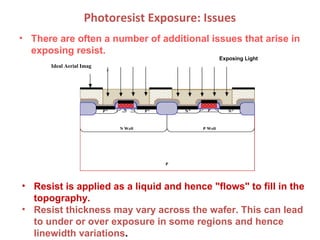

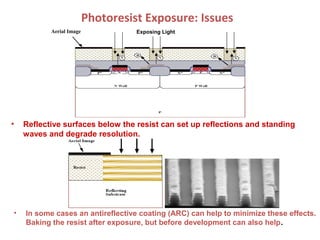

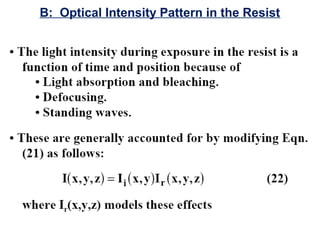

- Issues that can arise when exposing photoresist such as resist flowing, thickness variations, and reflections causing standing waves.

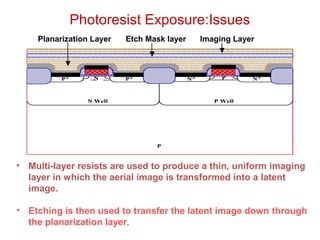

- The use of multi-layer resists and etching to produce a uniform imaging layer.

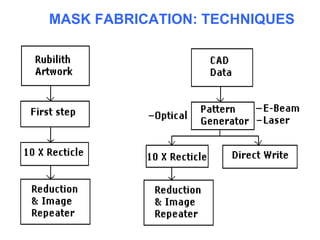

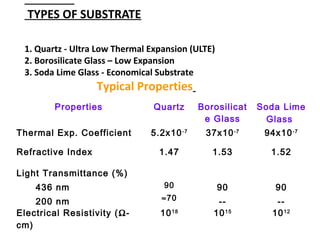

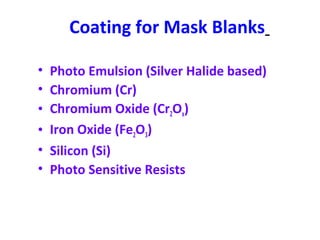

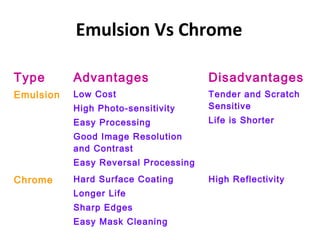

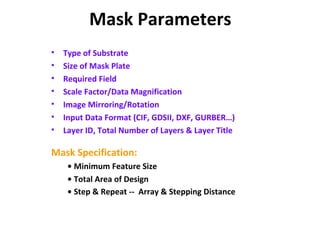

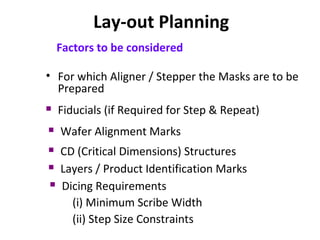

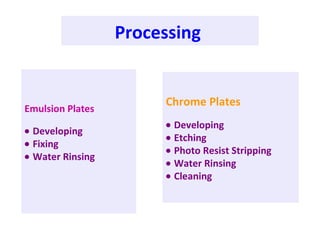

- Techniques for fabricating masks including the use of quartz, borosilicate glass, or soda lime glass substrates and coating materials like photoemulsion or chromium.

- Inspection and quality control of fabricated masks.

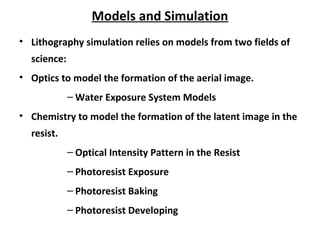

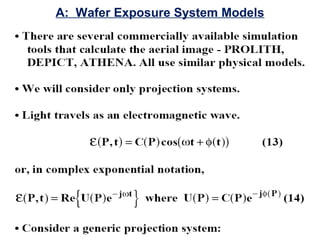

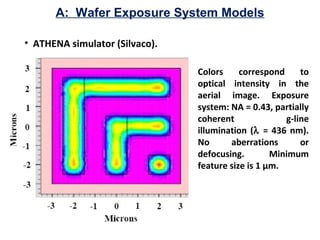

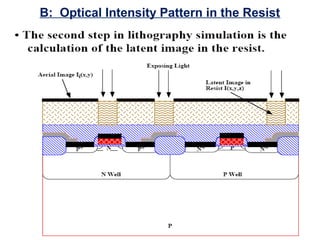

- Lithography simulation tools based on optical and resist chemistry models to simulate the aerial image and latent image formation.

![B: Optical Intensity Pattern in the Resist

• Example of calculation of light intensity distribution in a photoresist layer

during exposure using the ATHENA simulator. A simple structure is defined

with a photoresist layer covering a silicon substrate which has two flat regions

and a sloped sidewall.

The simulation shows the

[PAC] calculated

concentration after an

exposure of 200 mJ cm-2

.

Lower [PAC] values

correspond to more

exposure. The color

contours thus

correspond to the

integrated light intensity

from the exposure.](https://image.slidesharecdn.com/5-140603091155-phpapp02/85/5-2-lithography-3-4-5-final-2013-44-320.jpg)

![D: Photoresist Baking

• Same simulation example as last one except that a post exposure bake of 45

minutes at 115 °C has now been included. The color contours again

correspond to the [PAC] after exposure. Note that the standing wave effects

apparent earlier have been “smeared out” by this bake, producing a more

uniform [PAC] distribution.](https://image.slidesharecdn.com/5-140603091155-phpapp02/85/5-2-lithography-3-4-5-final-2013-50-320.jpg)