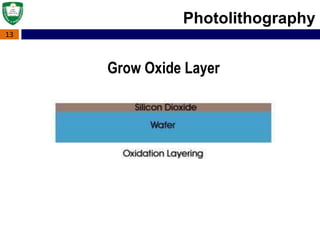

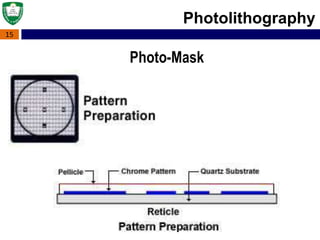

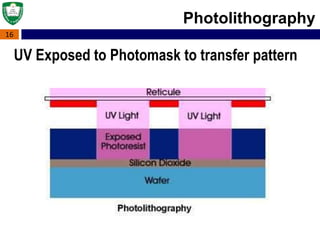

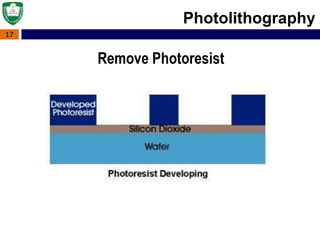

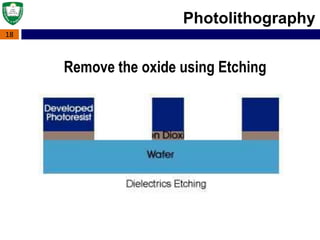

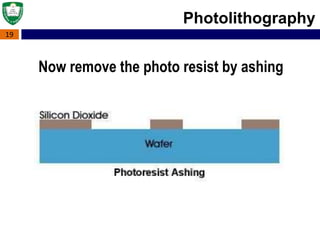

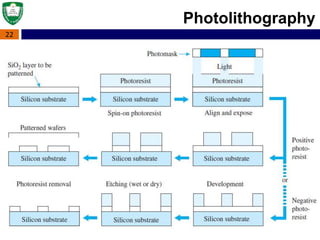

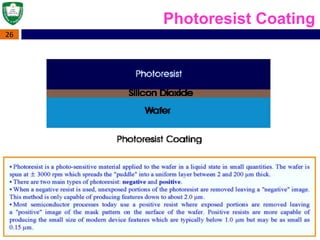

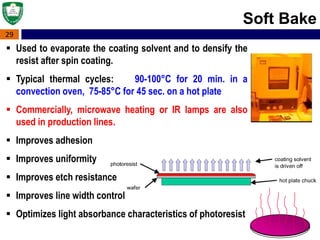

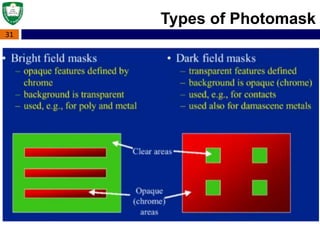

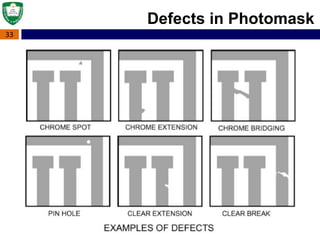

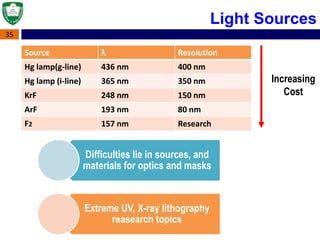

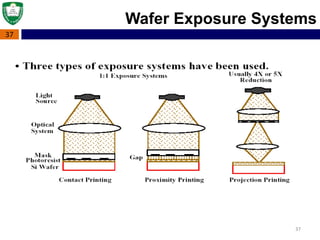

The document discusses various topics related to lithography. It begins by describing how a silicon wafer is prepared by polishing, sawing and doping to control its electrical properties. It then explains that photolithography involves coating a wafer with photoresist, exposing it to a photomask under UV light, and developing the resist to transfer the mask pattern. Several types of lithography are listed including photolithography, e-beam lithography and X-ray lithography. The document provides details on the photolithography process and discusses resolution limits of optical lithography.