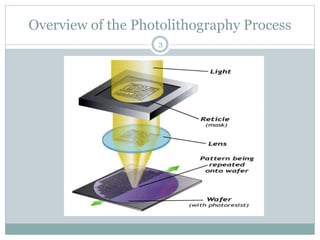

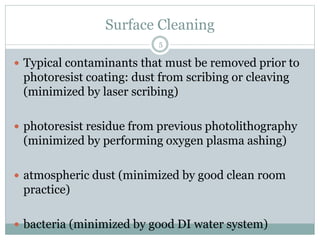

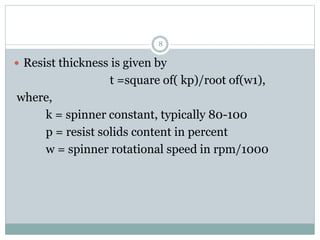

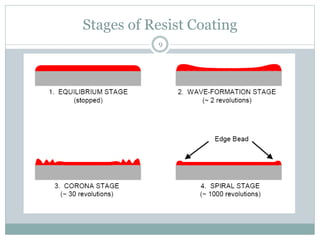

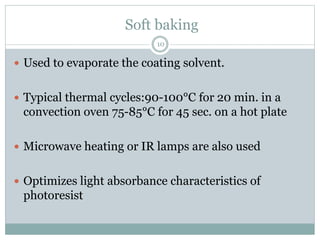

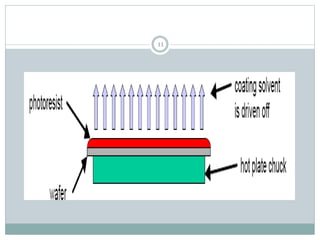

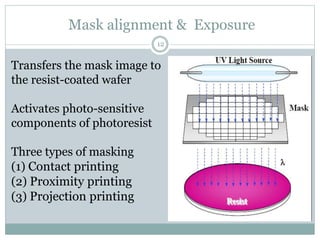

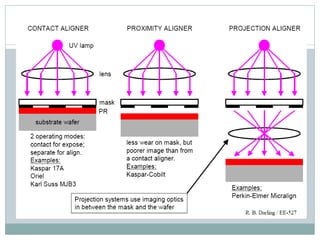

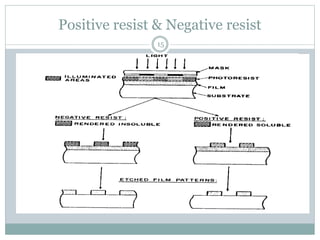

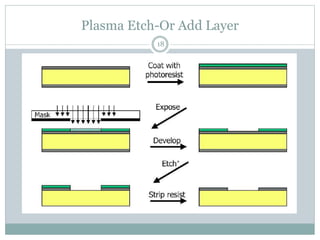

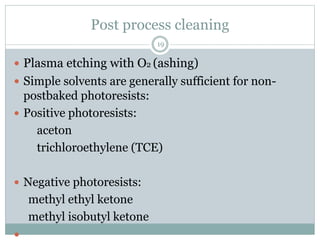

Lithography is a process used in semiconductor fabrication that involves transferring a geometric pattern from a photomask to a silicon wafer. It uses photo-sensitive chemicals and materials, along with UV light, to etch away parts of the wafer or add layers to it. The key steps in the lithography process are surface cleaning, spin coating photoresist, soft baking, mask alignment and exposure, development, hard baking, plasma etching or adding layers, post-process cleaning, and final inspection. Lithography allows for the precise patterning of integrated circuits on wafers.