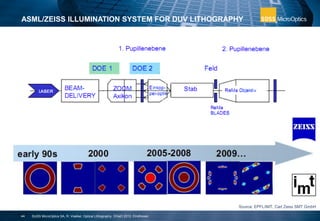

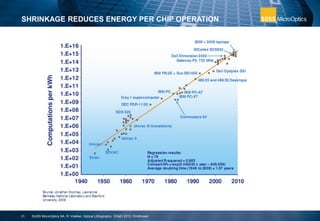

Dr. Reinhard Voelkel's presentation discusses the pivotal role of optical lithography as a foundational technology in modern electronics, especially in semiconductor manufacturing. He highlights historical advances and innovations, such as the development of integrated circuits and photoresists, which have propelled the industry forward. The talk also addresses the challenges faced by equipment suppliers in keeping pace with Moore's Law and the future prospects of lithography technology.

![HISTORIC LITHO TOOL PRICE [US$]

37

Mask Aligner

Front-End Litho Tool

EUVL

ASML 1950i

Every 4 years the price doubles

[1970 – 2010]

SUSS MicroOptics SA, R. Voelkel, Optical Lithography, DGaO 2012, Eindhoven](https://image.slidesharecdn.com/sussmicroopticsrvoelkellithographyatdgao2012eindhoven-130619043702-phpapp02/85/Optical-Lithography-Key-Enabling-Technology-for-our-Modern-World-35-320.jpg)