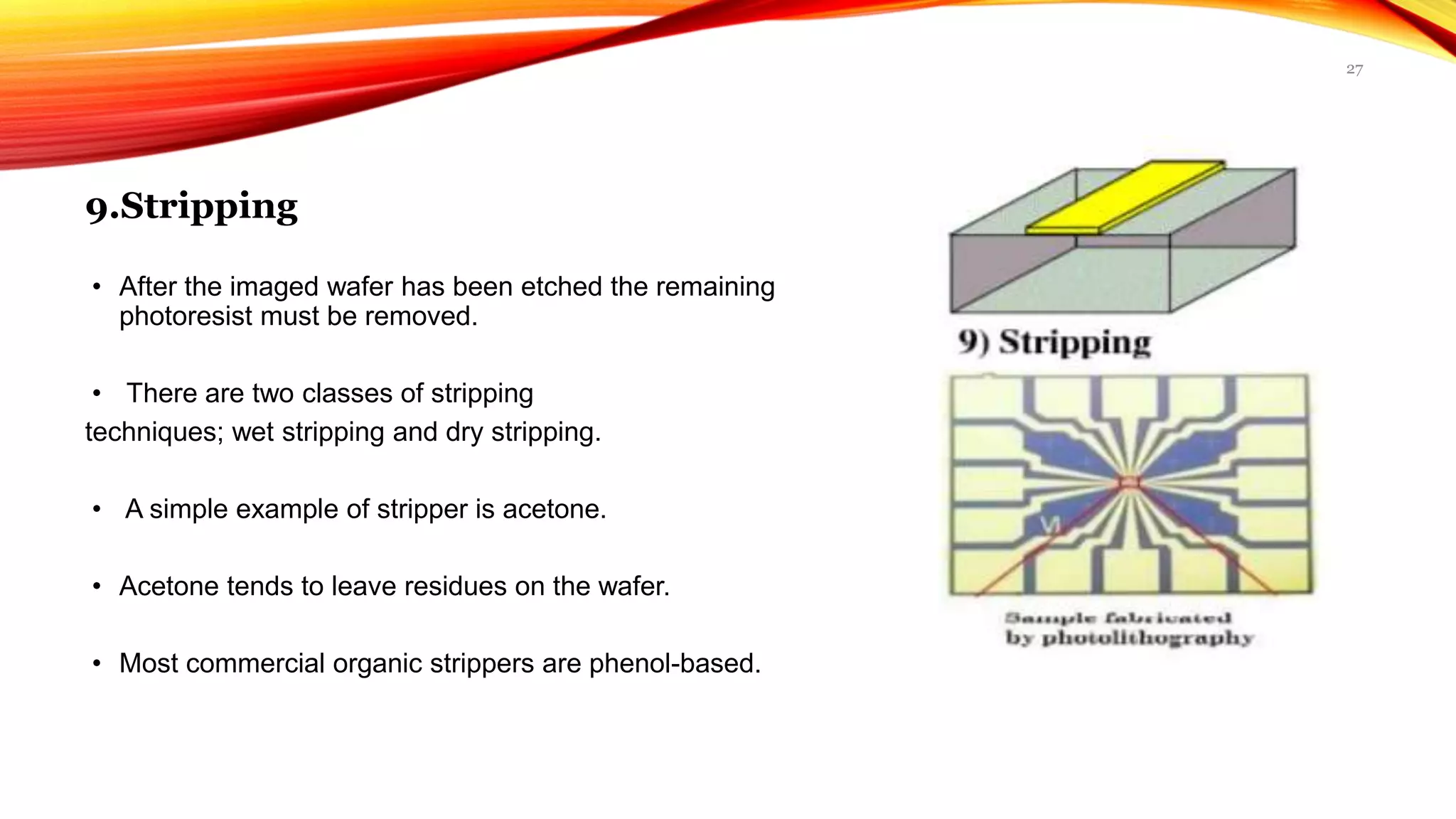

This document discusses lithography, a printing method that uses a smooth stone surface for creating artwork, and its applications in integrated circuit (IC) fabrication. It details the photolithography process, which involves transferring geometric patterns onto silicon wafers using light-sensitive polymers and various techniques to align and expose masks. The document also outlines the development, etching, and stripping processes involved in lithography, along with its advantages, disadvantages, and applications in the semiconductor industry.