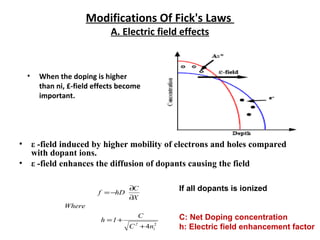

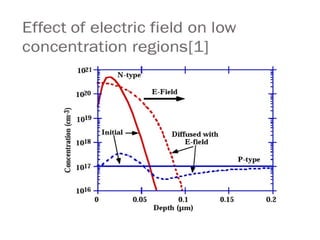

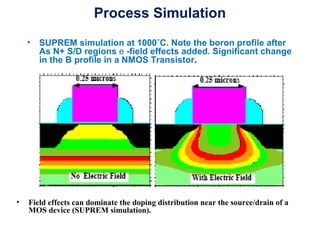

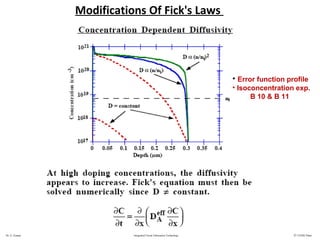

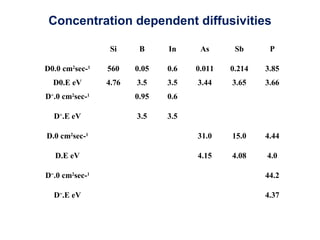

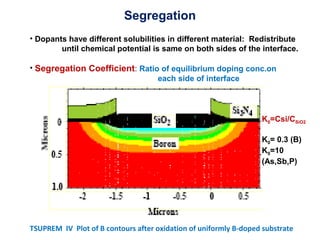

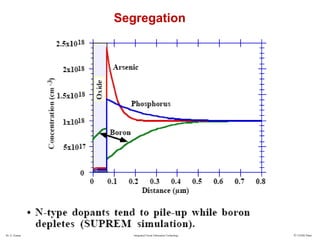

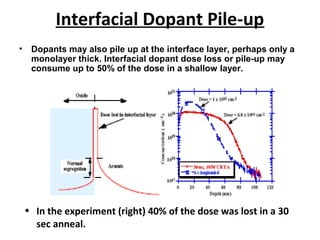

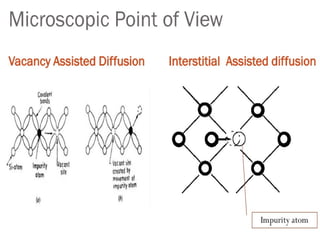

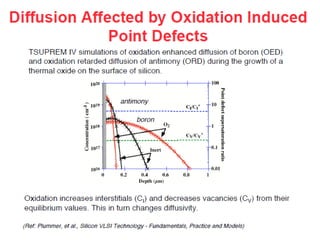

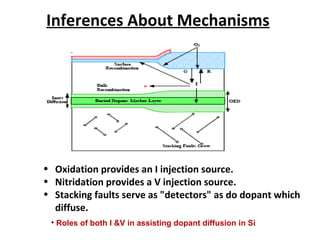

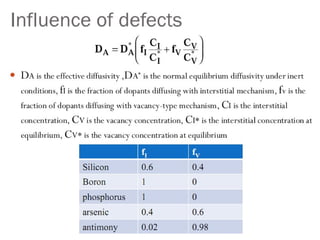

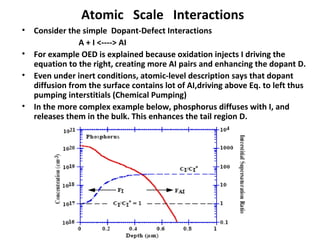

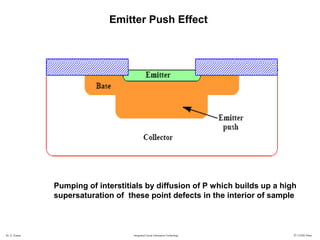

Microelectronics Technology discusses advanced models for dopant diffusion. Advanced models account for electric field effects, concentration-dependent diffusion, and dopant segregation. Some models are based on point defect driven diffusion at the atomic scale. Modifications to Fick's laws are also discussed, including electric field enhancement effects which become important at higher doping concentrations. Process simulations demonstrate how electric fields can dominate doping distribution near MOS device source/drain regions. Concentration dependent diffusivities and dopant segregation effects are also covered.