Embed presentation

Downloaded 17 times

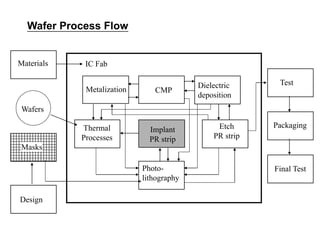

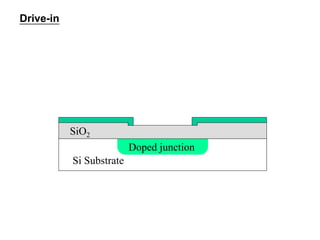

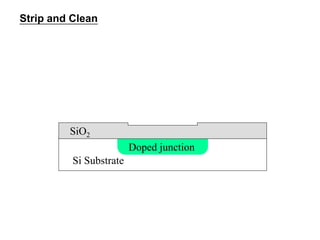

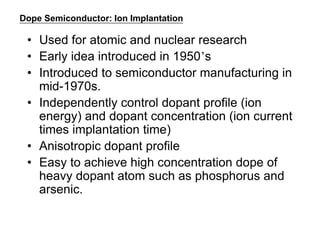

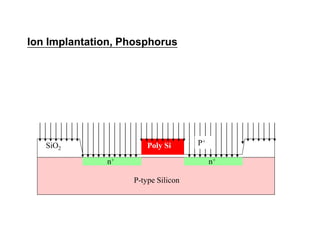

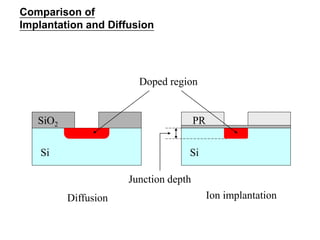

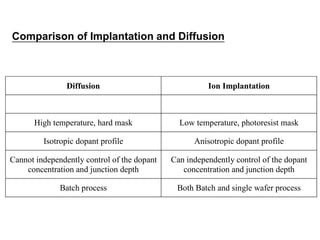

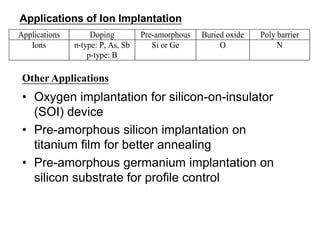

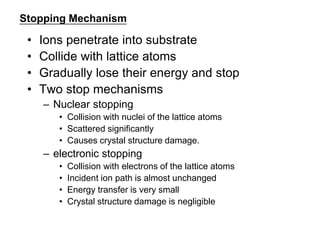

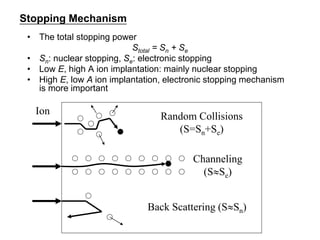

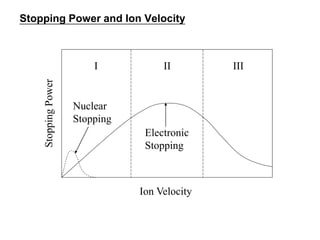

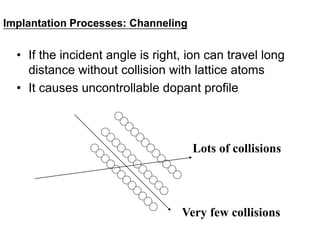

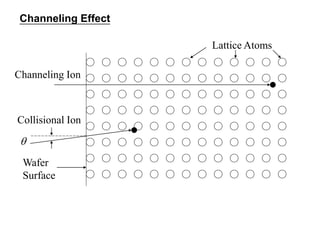

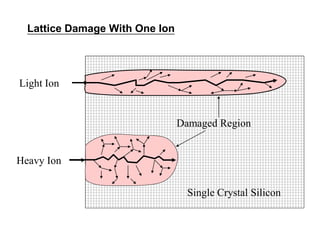

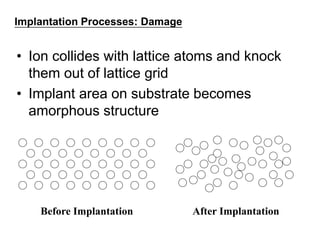

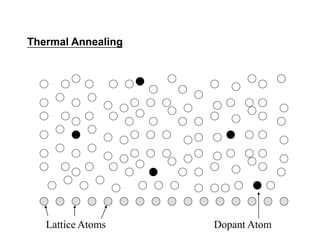

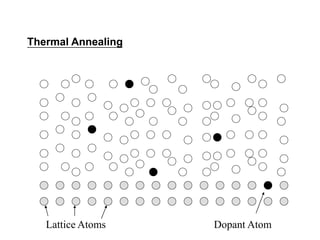

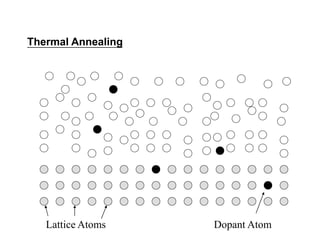

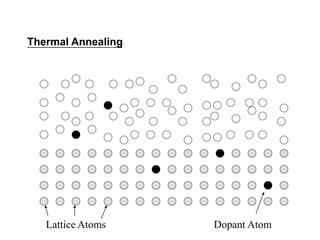

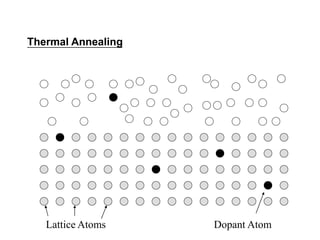

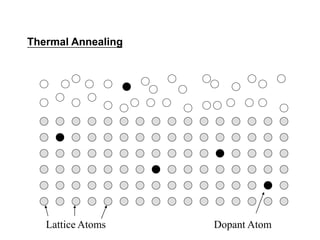

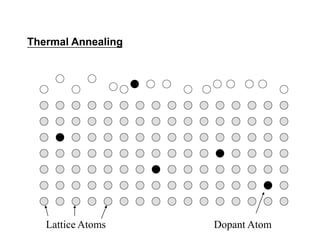

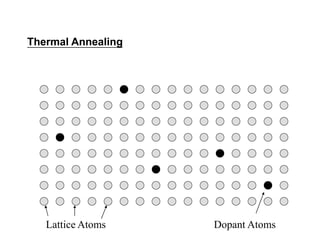

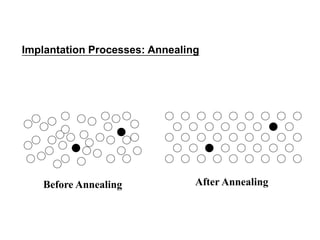

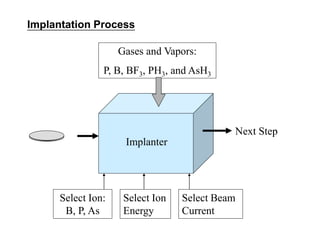

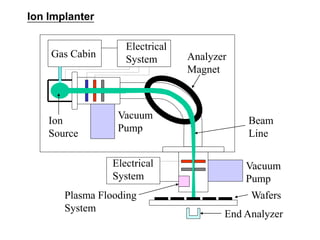

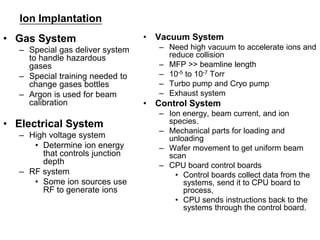

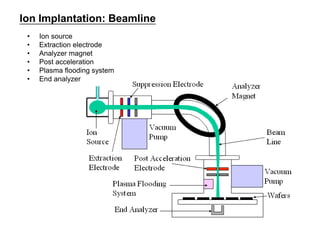

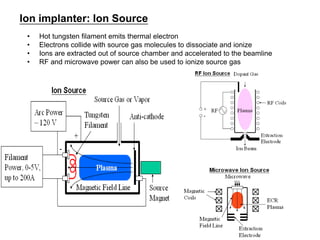

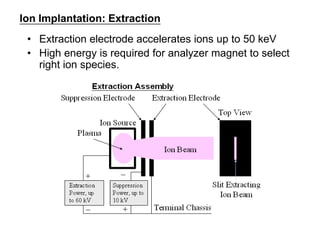

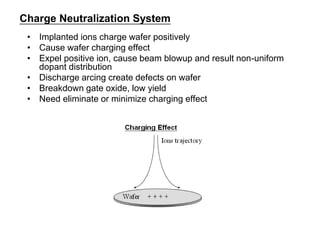

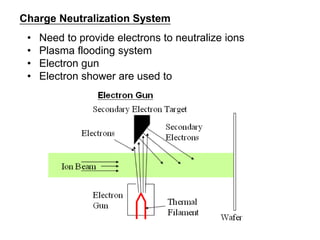

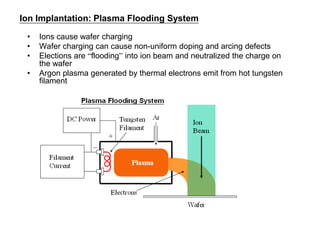

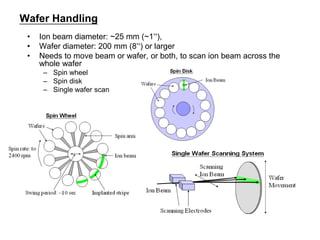

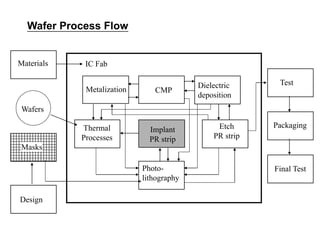

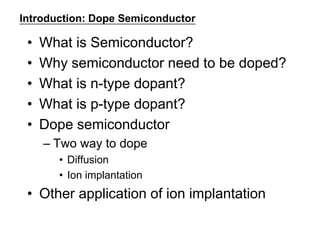

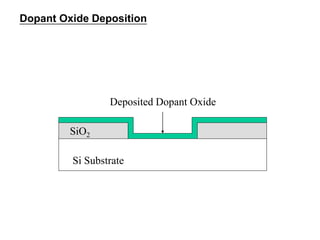

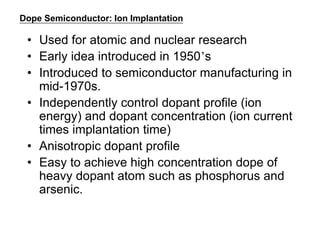

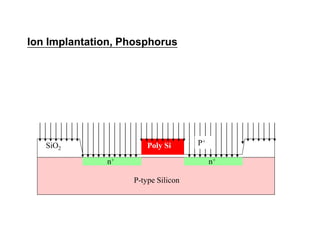

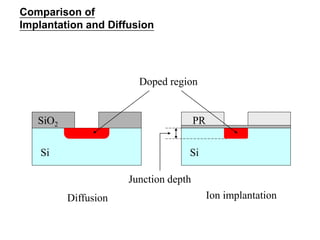

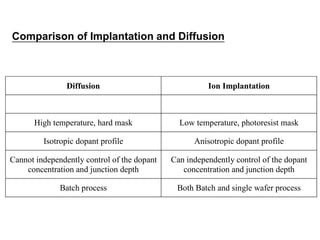

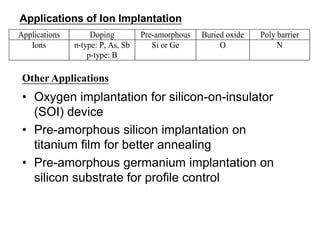

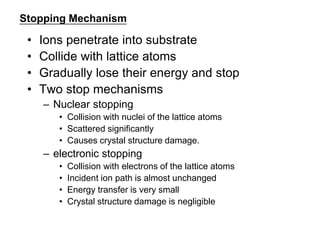

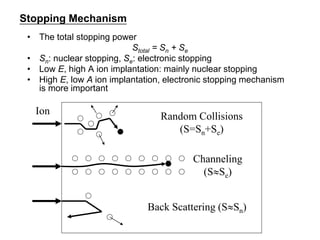

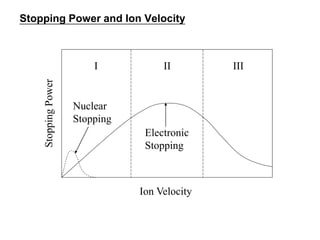

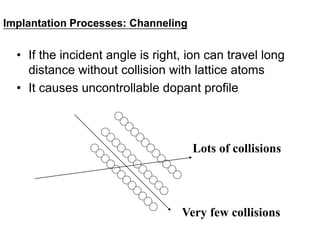

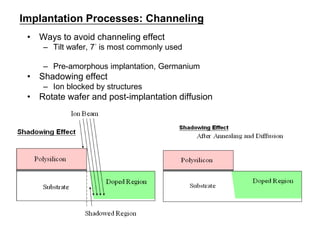

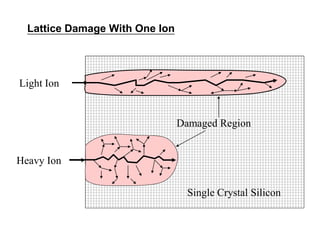

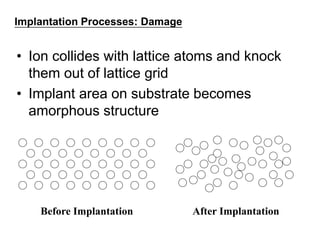

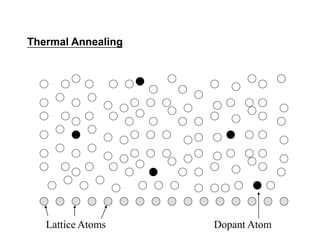

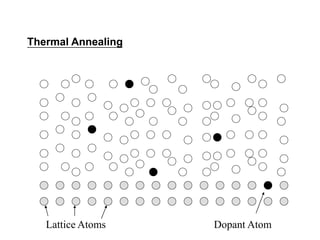

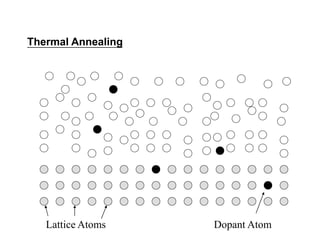

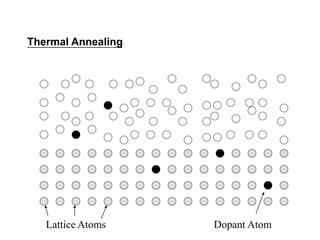

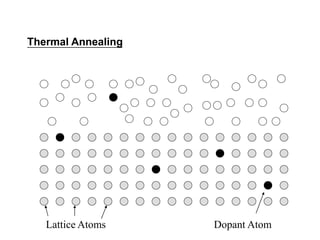

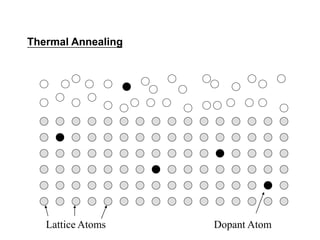

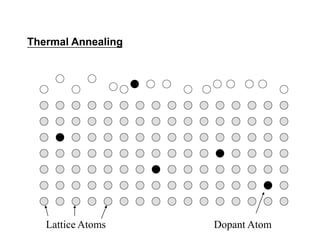

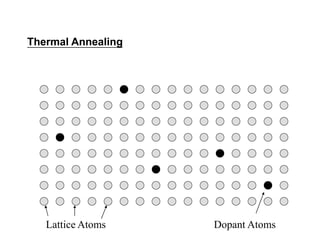

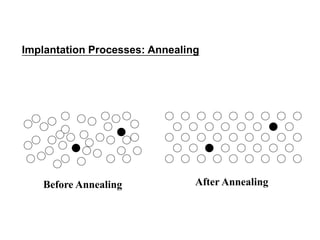

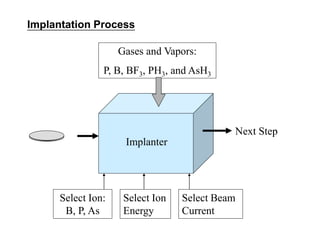

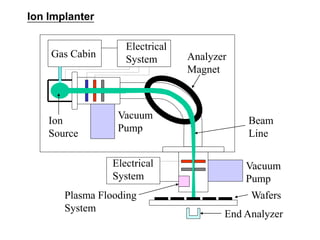

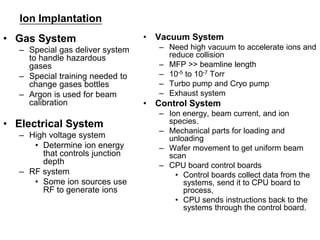

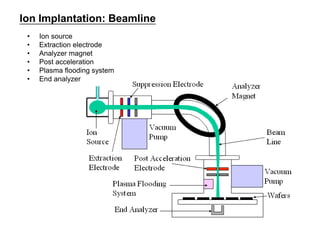

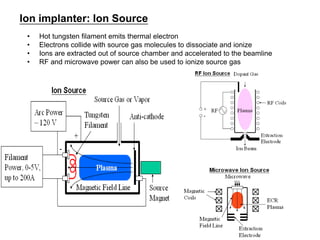

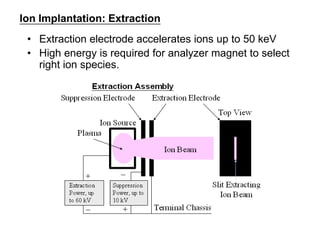

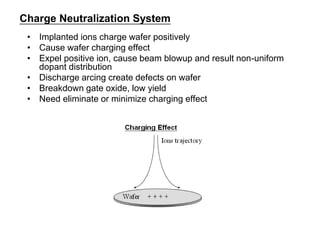

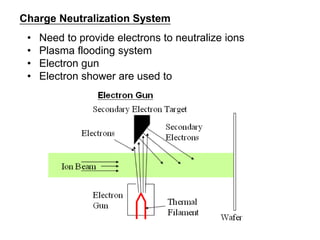

Ion implantation is a process used to dope semiconductors by bombarding them with ions. It allows independent control of dopant profile and concentration. Ions are ionized from source gases, accelerated, selected by mass, and implanted into wafers. Implanted ions damage the crystal structure which is repaired by annealing. Ion implantation offers anisotropic doping, low temperature processing, and precise doping levels compared to diffusion.