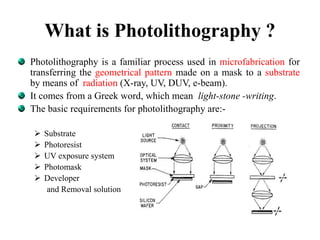

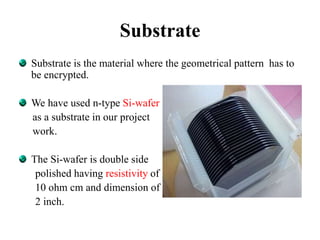

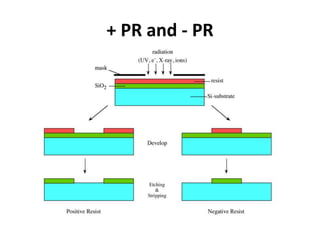

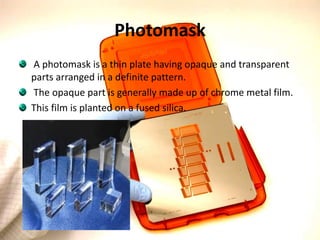

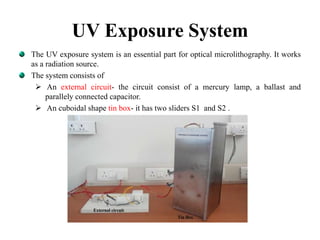

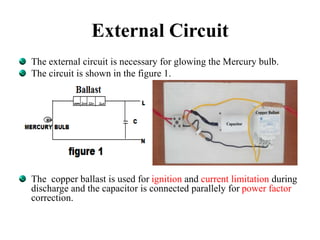

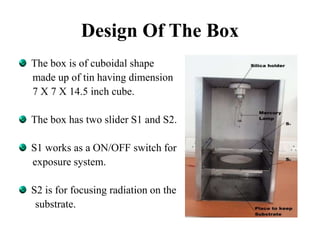

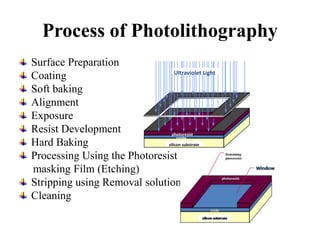

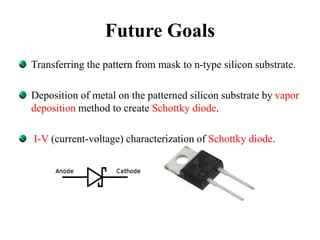

The document details the process and components of photolithography, including the definition, requirements such as substrate and photoresist, and the advantages of positive over negative photoresist. It describes the construction of a UV exposure system and the steps involved in photolithography, from surface preparation to pattern transfer and metal deposition. Future goals include creating a Schottky diode and conducting I-V characterization.