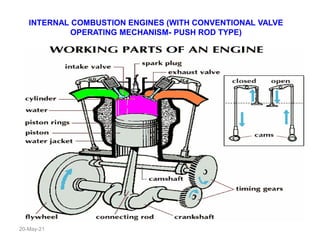

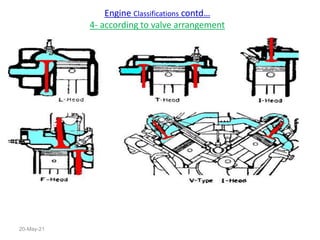

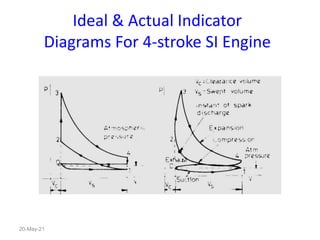

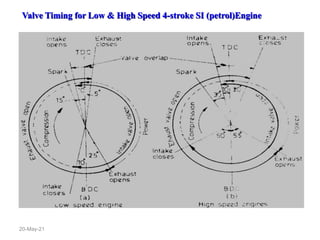

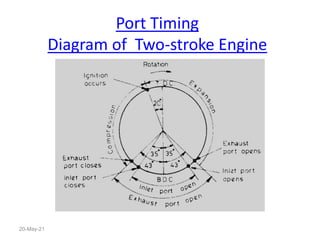

This document provides an introduction to internal combustion engines. It discusses engine classifications based on cycle of operation, combustion cycle, arrangement of cylinders, valve arrangement, fuel used, mixture preparation method, ignition method, combustion chamber design, and method of load and cooling control. It also describes the components, nomenclature, ideal and actual indicator diagrams, valve timing diagrams, port timing diagrams, and comparisons of two-stroke SI and CI engines. Advantages and applications of SI and CI engines are outlined.