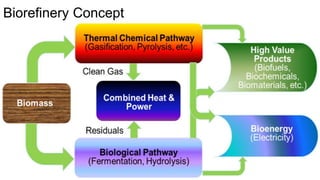

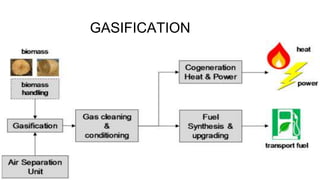

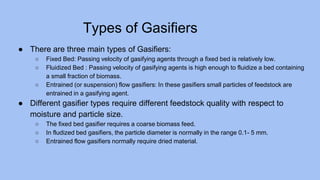

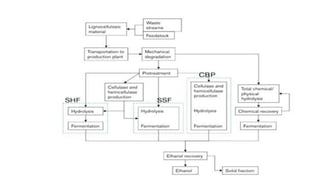

This document provides an overview of biorefineries. It defines a biorefinery as a refinery that converts biomass into energy and other beneficial byproducts. The document then discusses the uses of biorefineries, how they function, and the types of biorefineries including classification based on platforms, products, feedstocks, and processes used. It also describes the major biorefinery platforms of thermochemical/syngas and biochemical/sugar, and important feedstocks like sugar, starch, and lignocellulosic materials. Gasification and types of gasifiers and fermentation of lignocellulosic feedstock are also summarized.