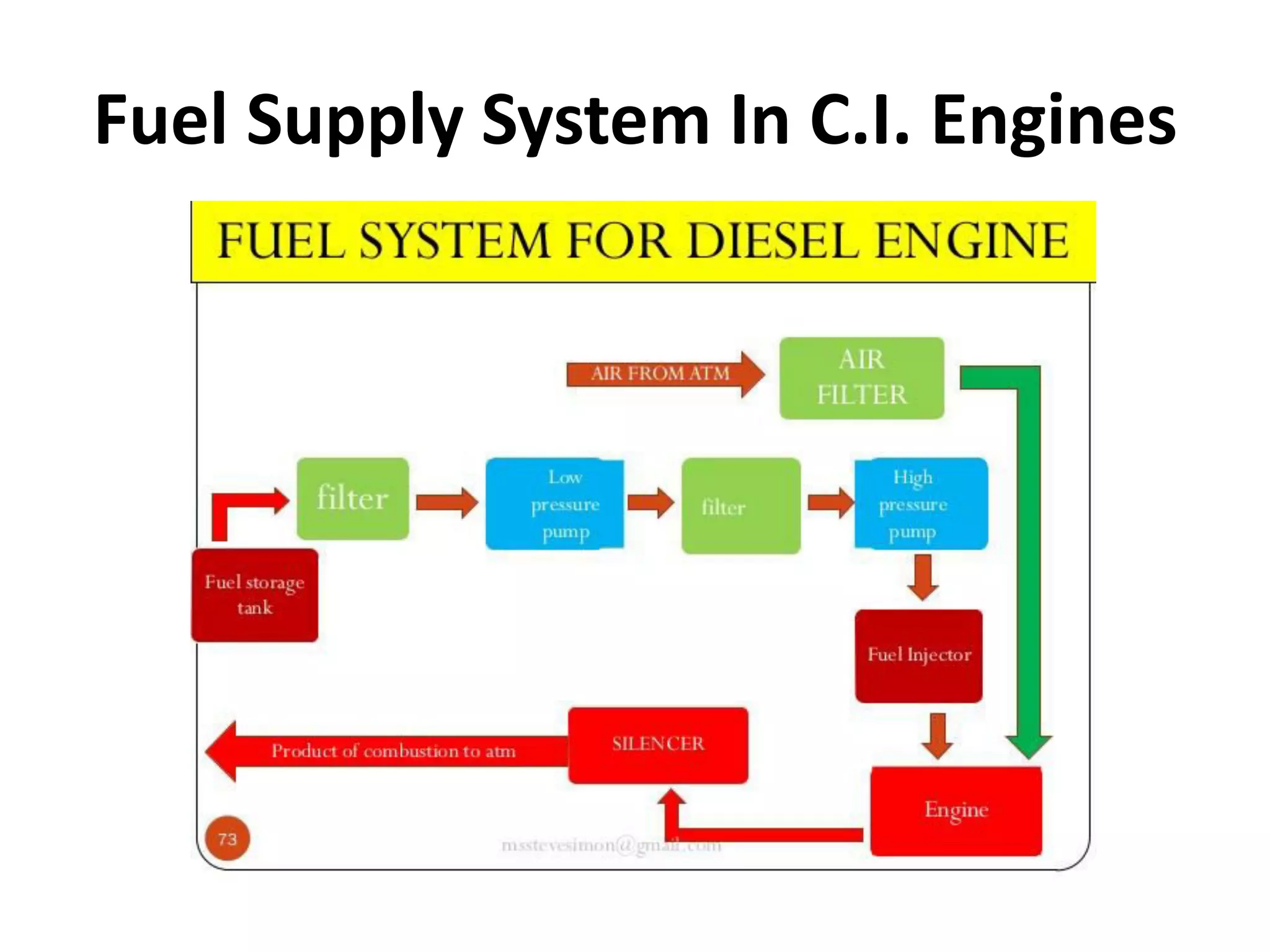

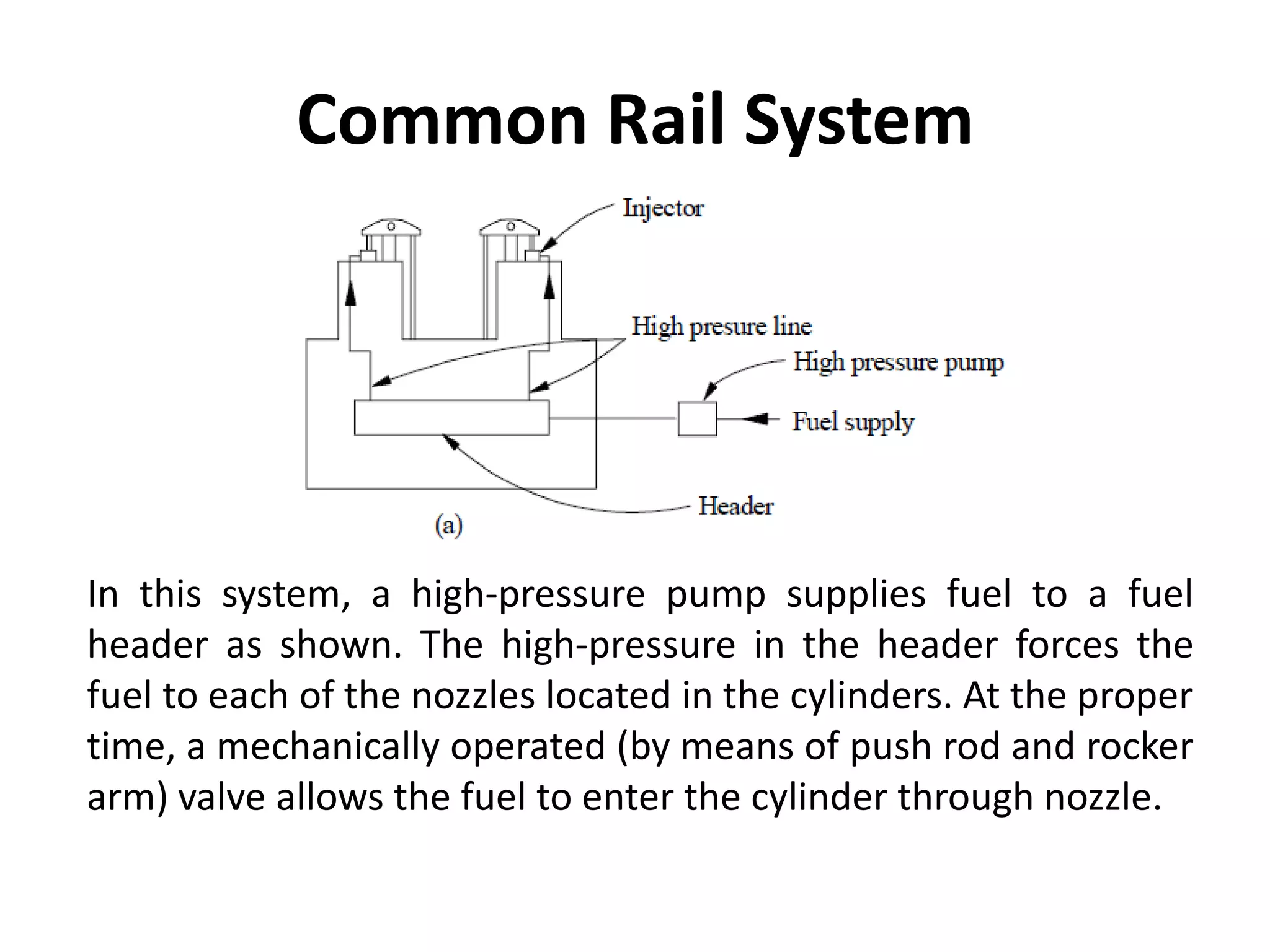

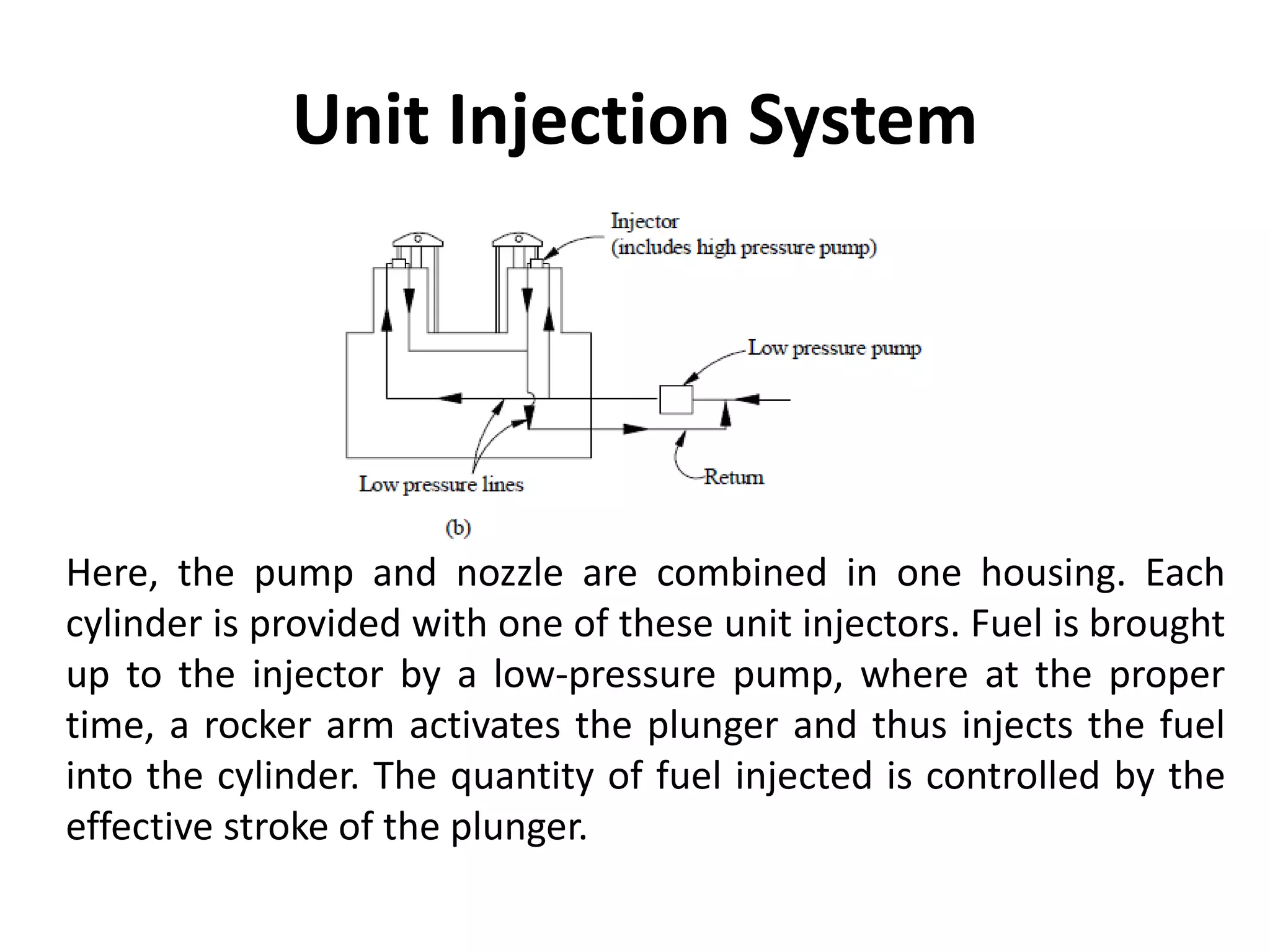

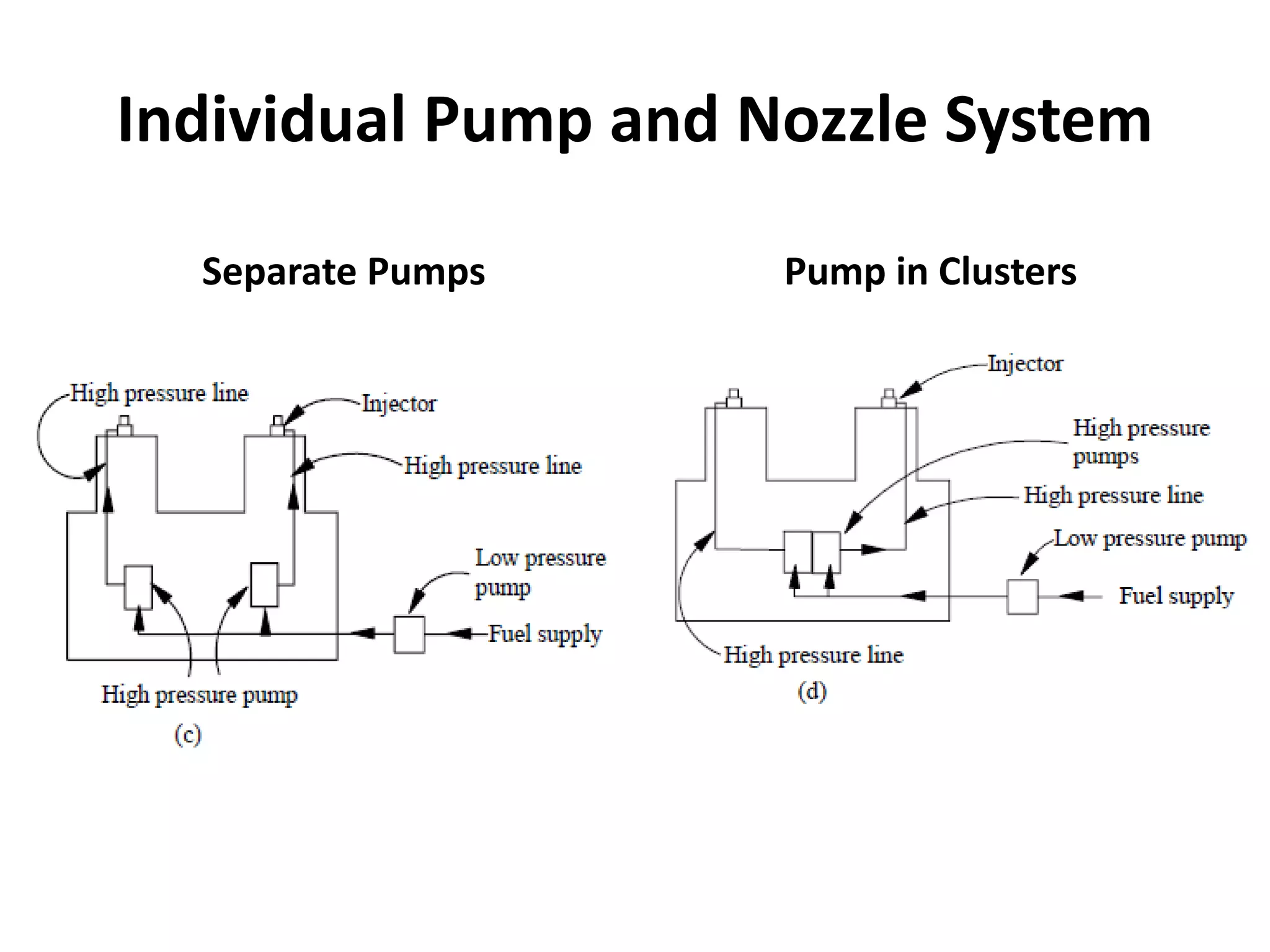

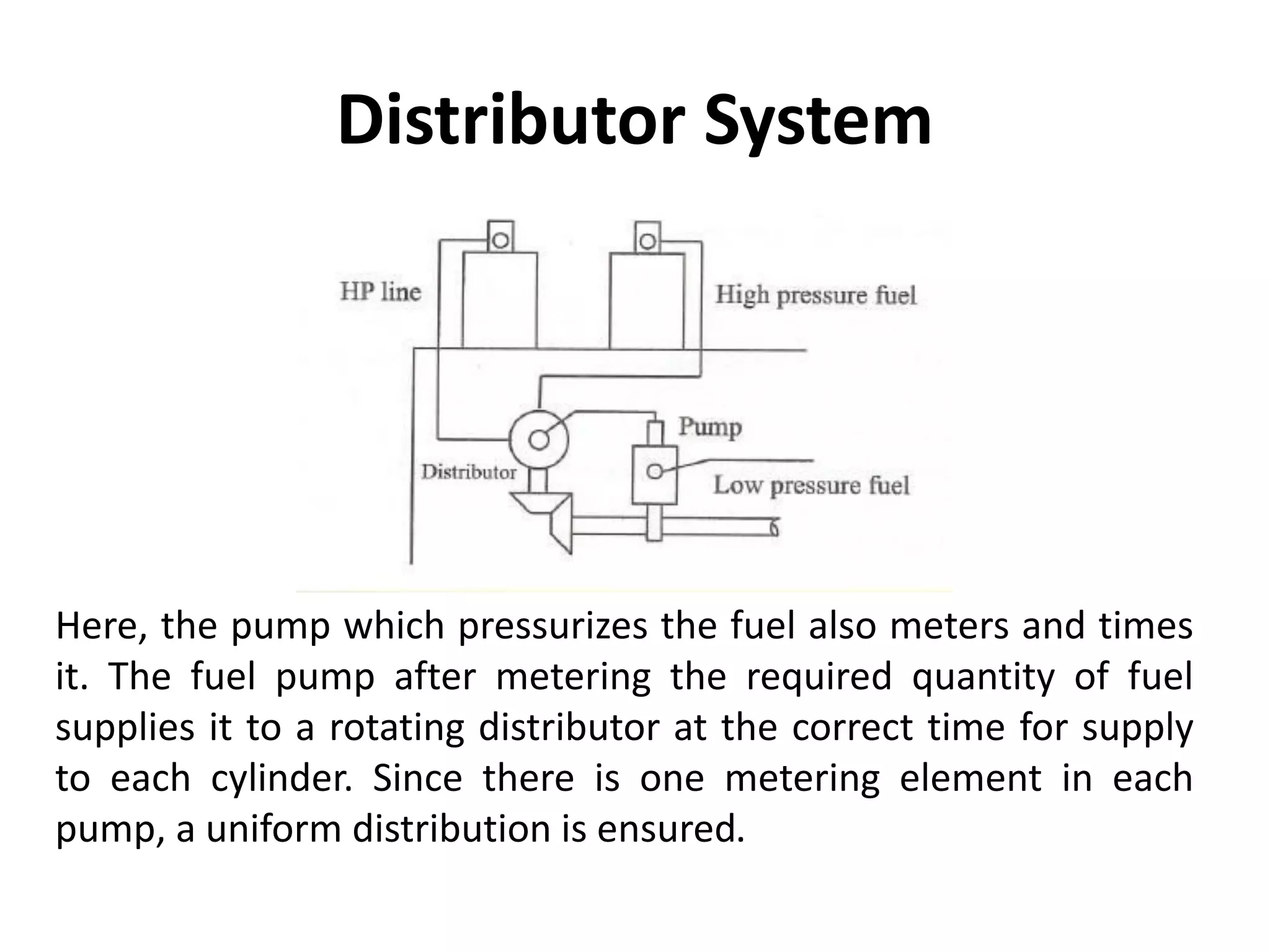

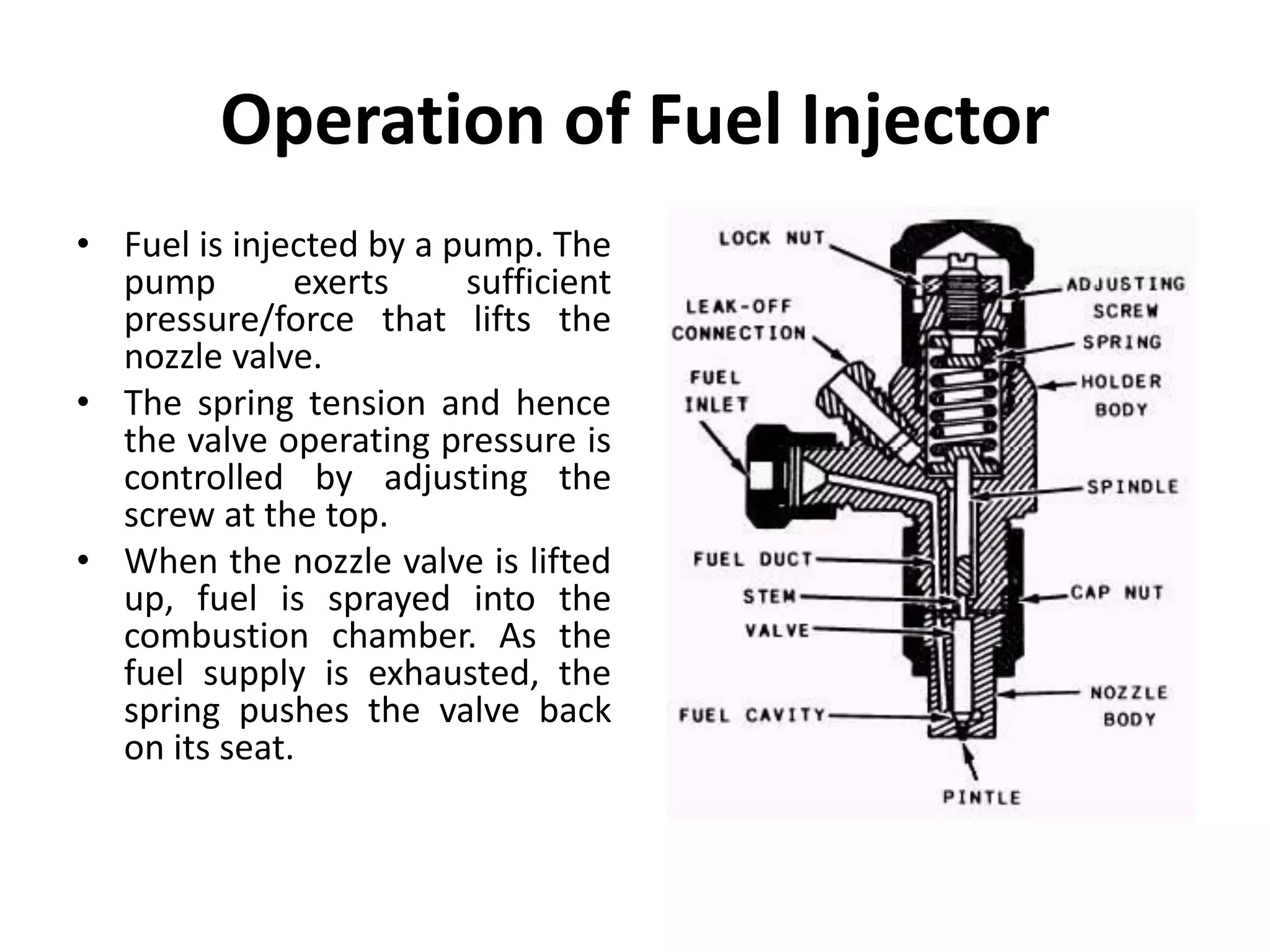

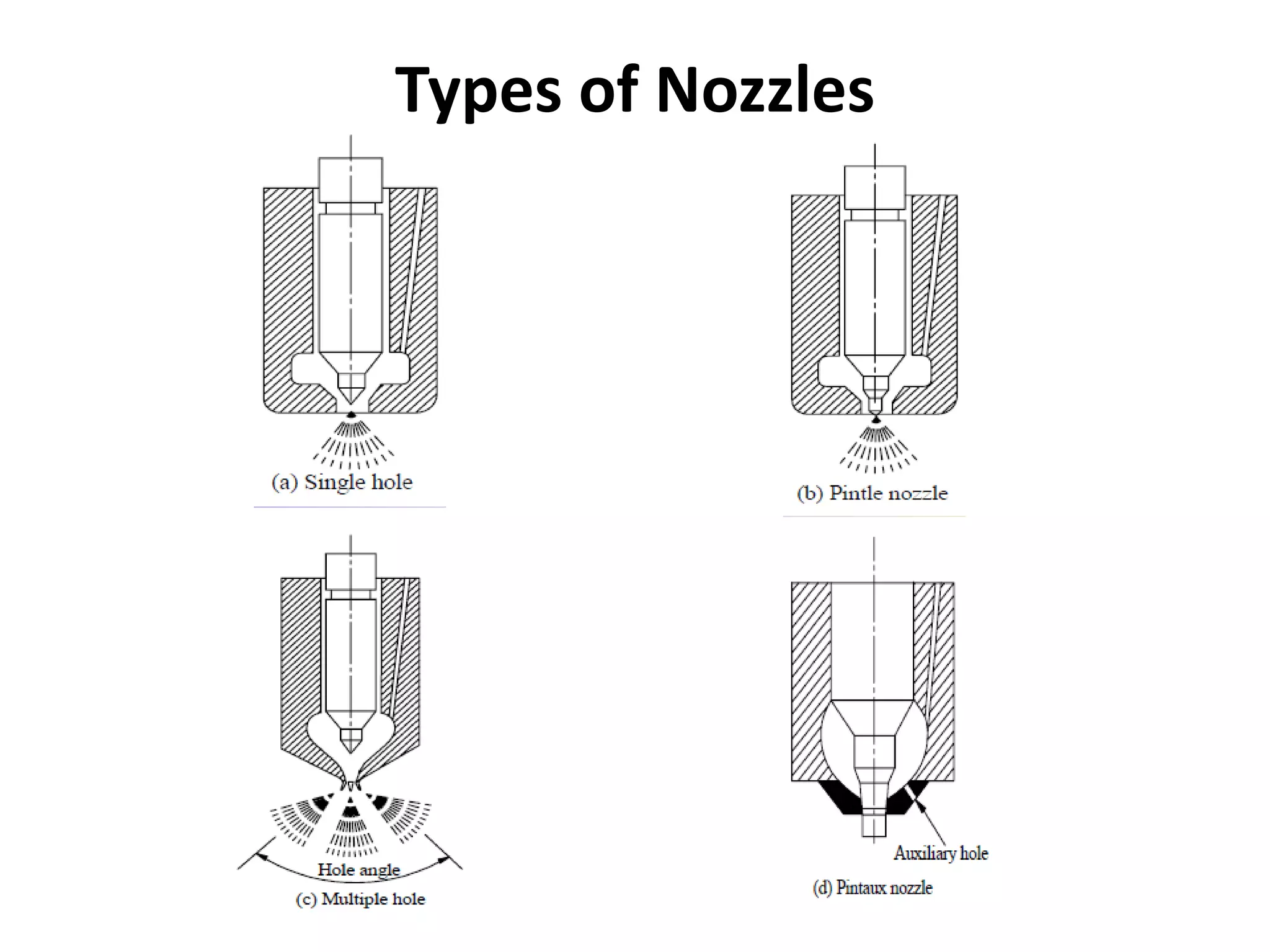

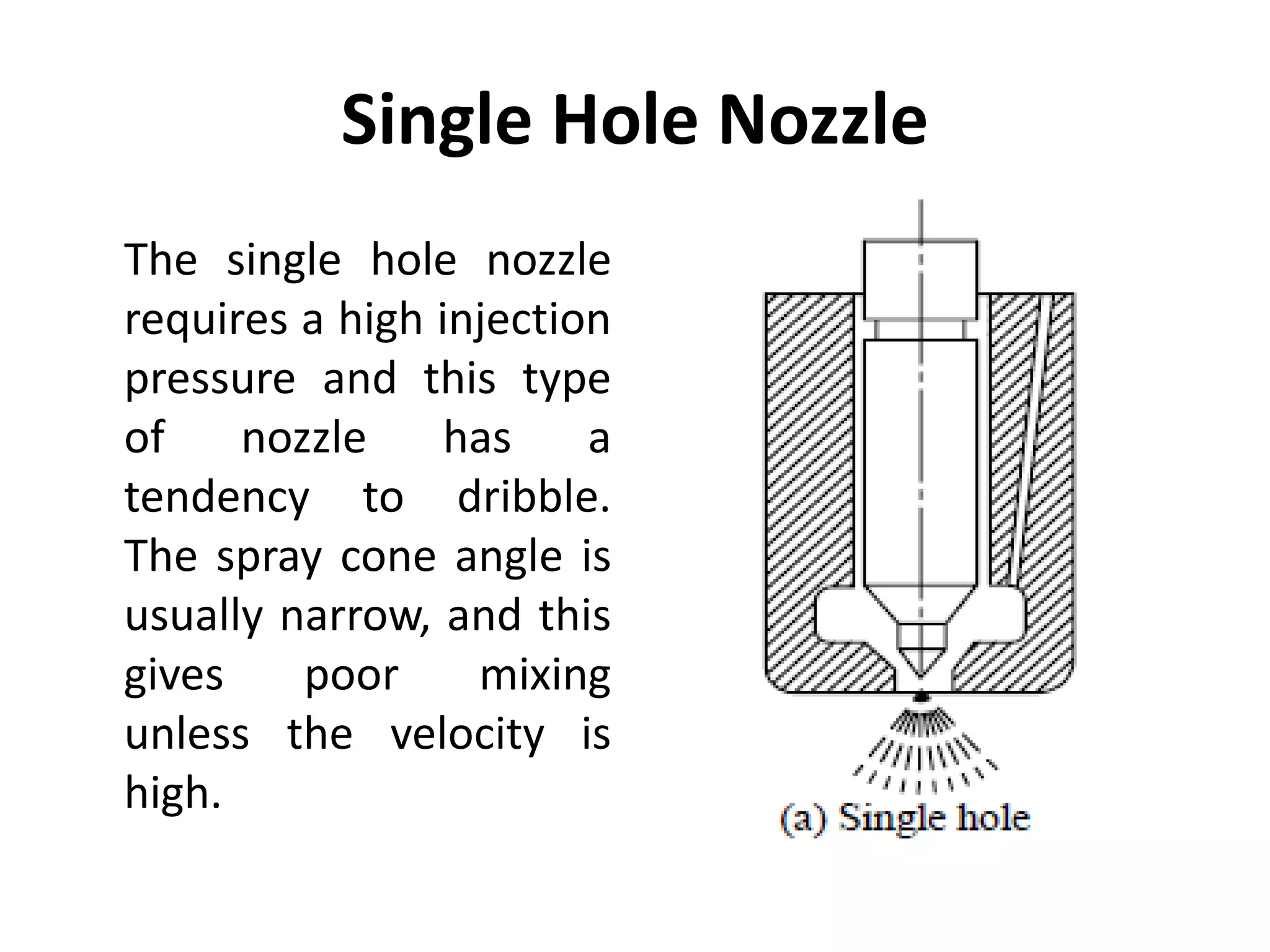

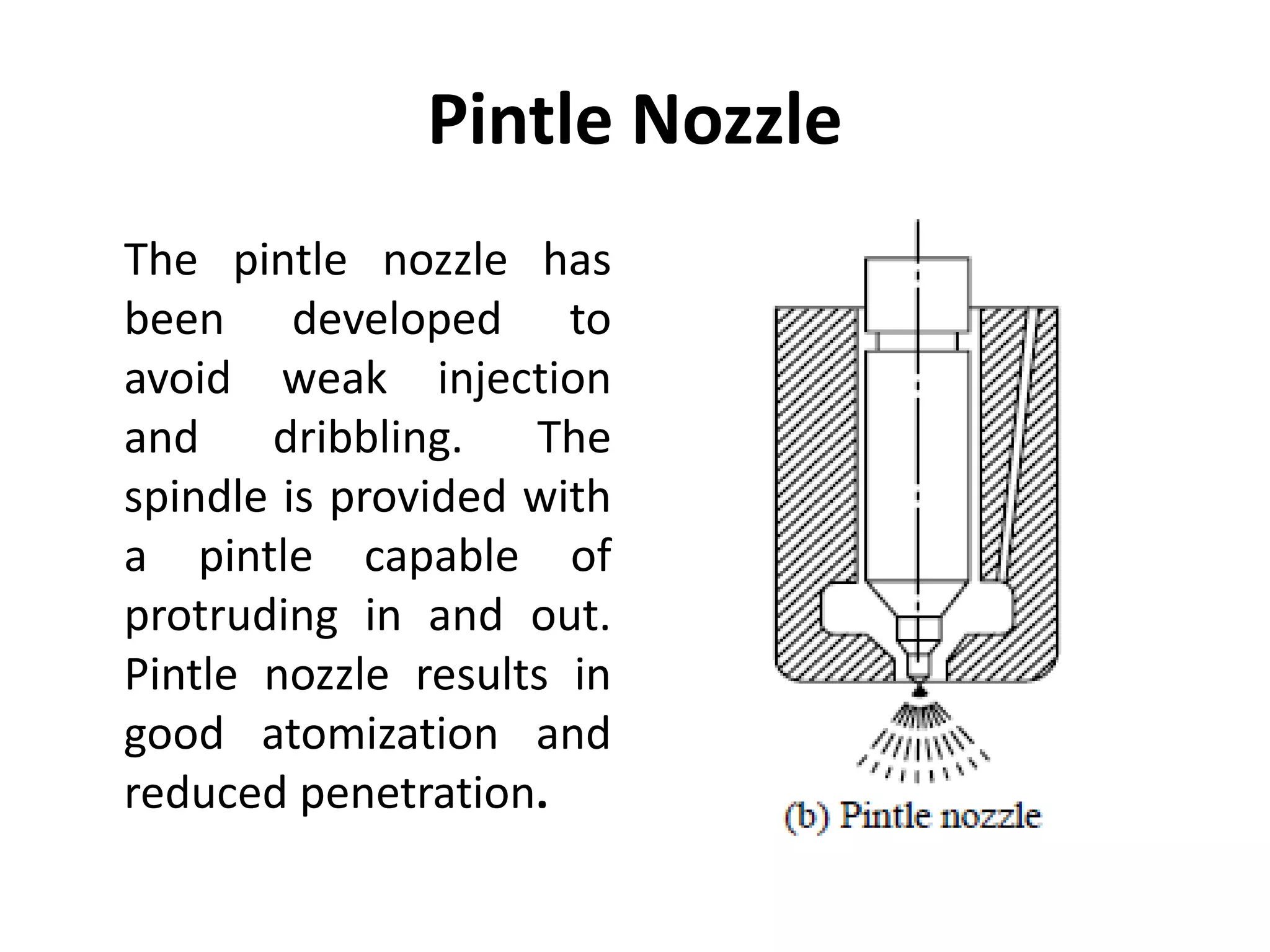

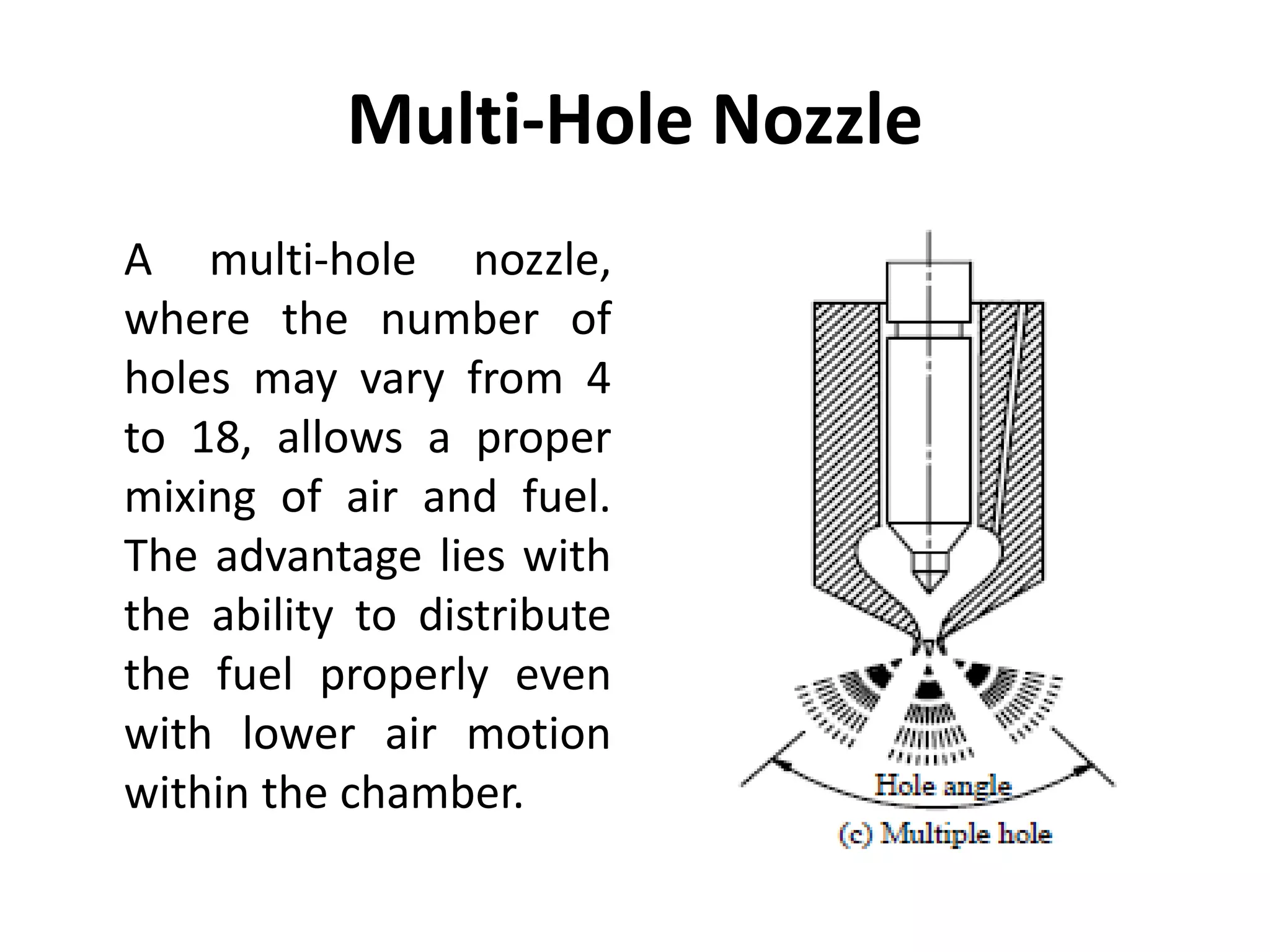

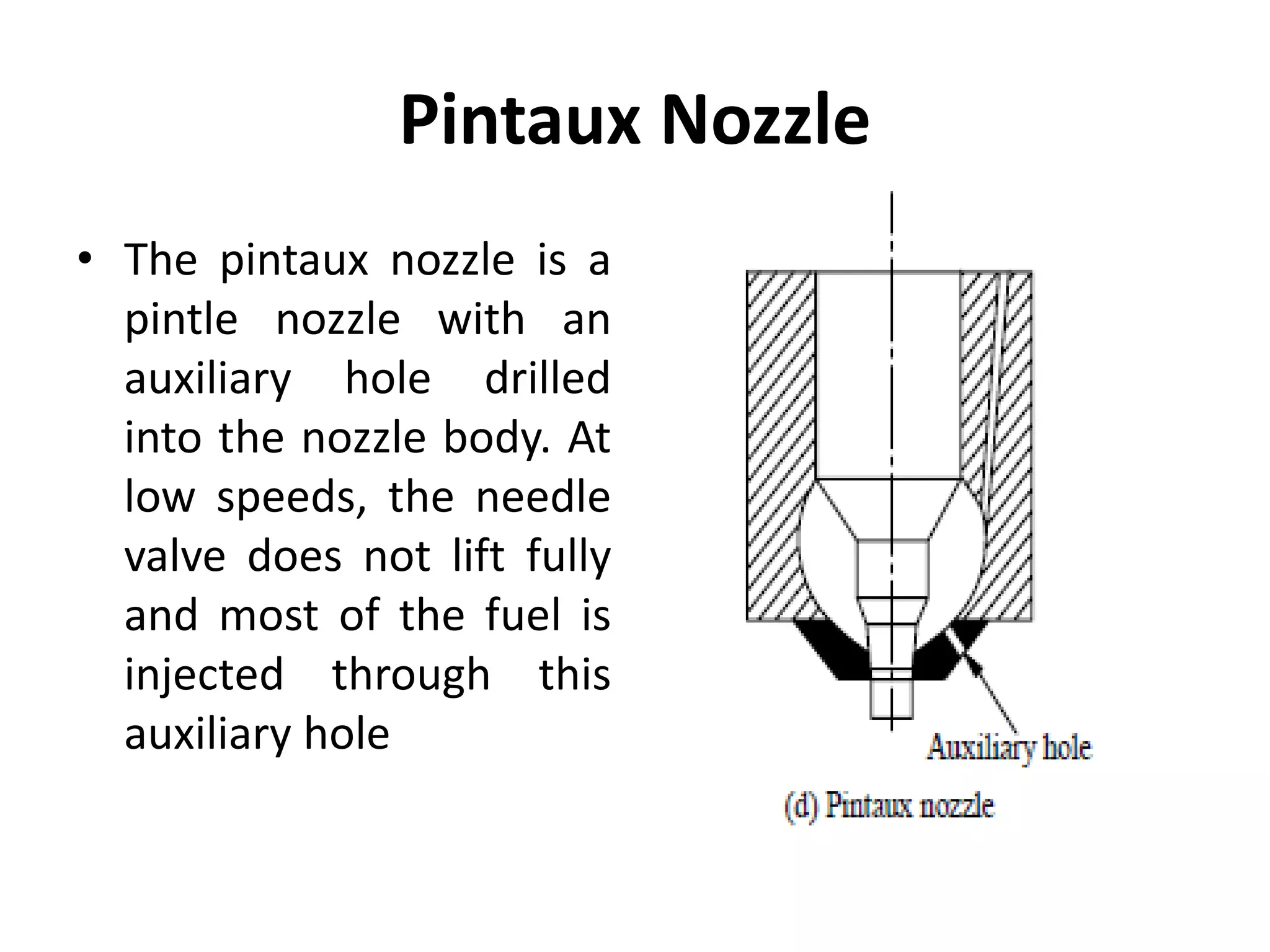

The document discusses fuel injection systems for diesel engines. It describes the key elements of fuel injection systems including pumping, metering, distribution, and timing controls. It outlines different types of injection systems such as common rail, unit injection, individual pump and nozzle, and distributor systems. It also discusses the injection pump, fuel injector, nozzle types, and operation of the fuel injector.