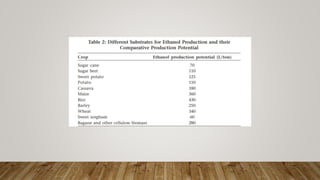

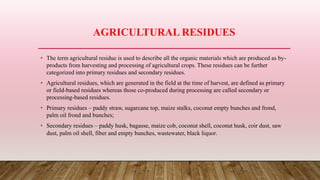

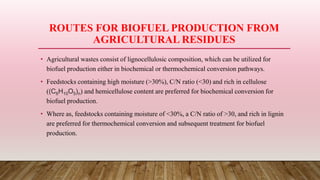

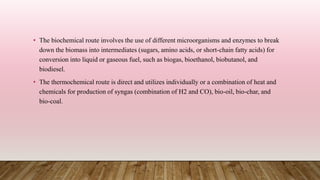

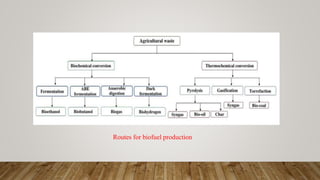

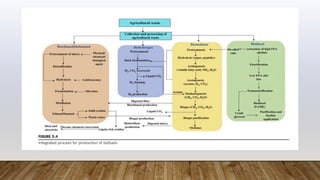

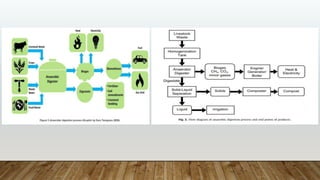

The document discusses different types of biomass available for energy production. It describes biomass as organic matter derived from plants and animals that can be used as an energy source. The main types of biomass discussed are energy crops, agricultural residues, and animal wastes. Energy crops include food and oil crops that can be grown as fuel. Agricultural residues are byproducts of crop harvesting and processing. Animal wastes can be converted to biogas through anaerobic digestion or other thermal processes.

![ENERGY PLANT SPECIES

• Energy plant species are understood to mean those annual and perennial species that can be cultivated to

produce solid , liquid, or gaseous energy feedstocks.

• Energy plant species could include roots, tubers, stems, branches, leaves, fruits and seeds or even whole

plants.

• All plant species that store primarily carbohydrates or oils are suitable for producing liquid energy

resources. Cellulose , starch, sugar can be used to produce ethanol. Vegetable oils can be used as fuels.

Parts of plants containing lignocellulose can provide energy directly as solid fuels or indirectly after

conversion.

• The number of plant species that can be utilised as solid biofuels is much higher than those usable for

ethanol and oil production[1]. The level of production of these crops is largely influenced by the

availability of water besides the genetic potential.](https://image.slidesharecdn.com/biomassavailabilityandtypes-210520180311/85/Bio-mass-availability-and-types-5-320.jpg)

![REFERENCES:

[1] https://www.google.co.in/books/edition/Energy_Plant_Species/QDS8URpY4zYC?hl=en&gbpv=1

[2] https://pubs.rsc.org/en/content/articlelanding/2019/gc/c8gc02698j/unauth#!divAbstract

[3] https://www.slideshare.net/zohaibkhan404/energy-crops-their-worldwide-usage-data-and

[4] https://ris.org.in/sites/default/files/article3_v8n2.pdf

[5] https://www.researchgate.net/publication/270395790_An_overview_of_biofuels_from_energy_crops_Current_status_and_future_prospects/link/5e9b3d0ca6fdcca789244009/

[6] https://tammi.tamu.edu/2017/07/17/manure-energy-understanding-processes-principles-jargon/

[7] https://www.bioenergyconsult.com/tag/animal-wastes/

[8] https://www.sciencedirect.com/science/article/abs/pii/S1364032119301042

[9] https://www.hindawi.com/journals/jchem/2015/630168/](https://image.slidesharecdn.com/biomassavailabilityandtypes-210520180311/85/Bio-mass-availability-and-types-29-320.jpg)