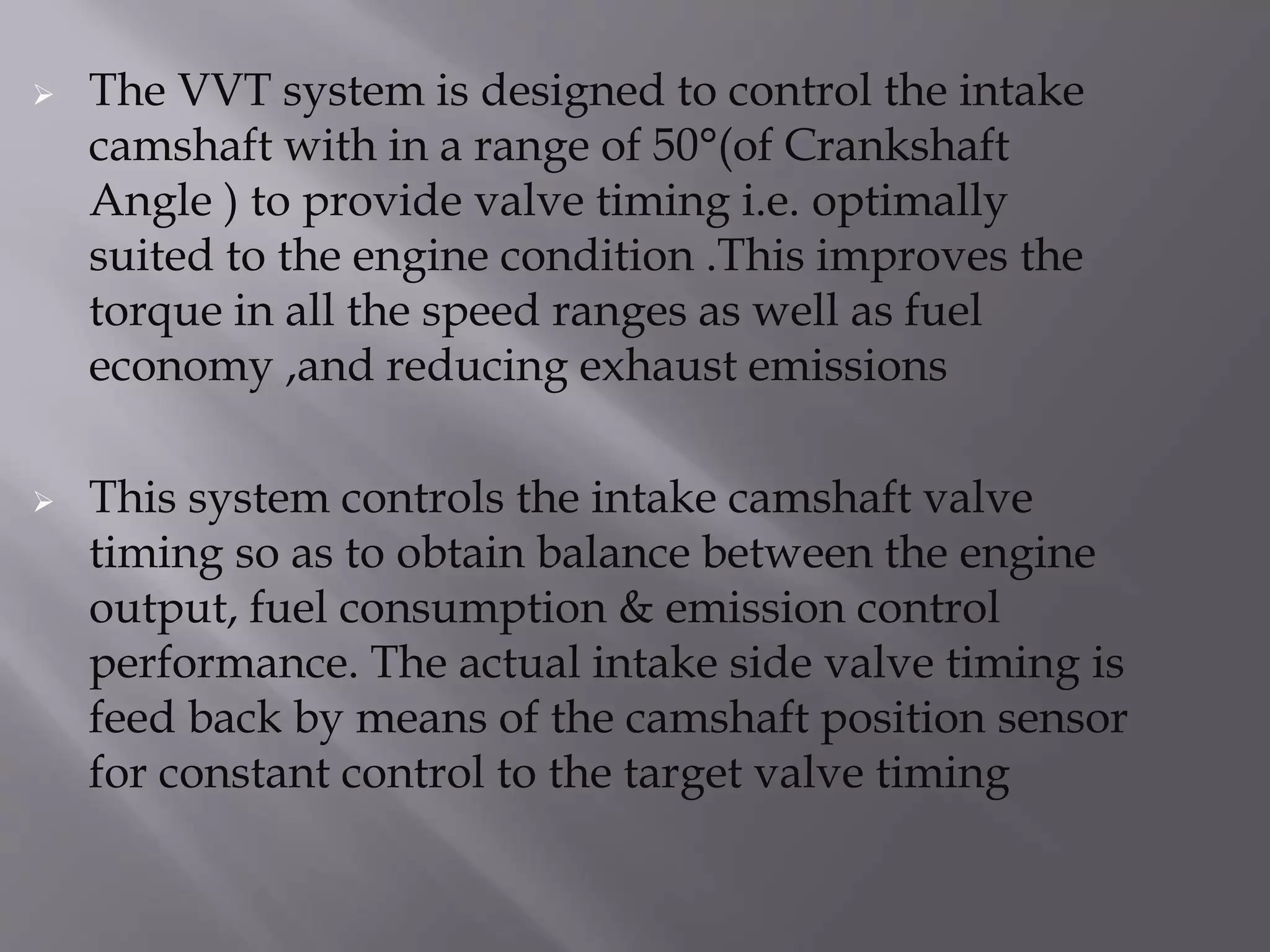

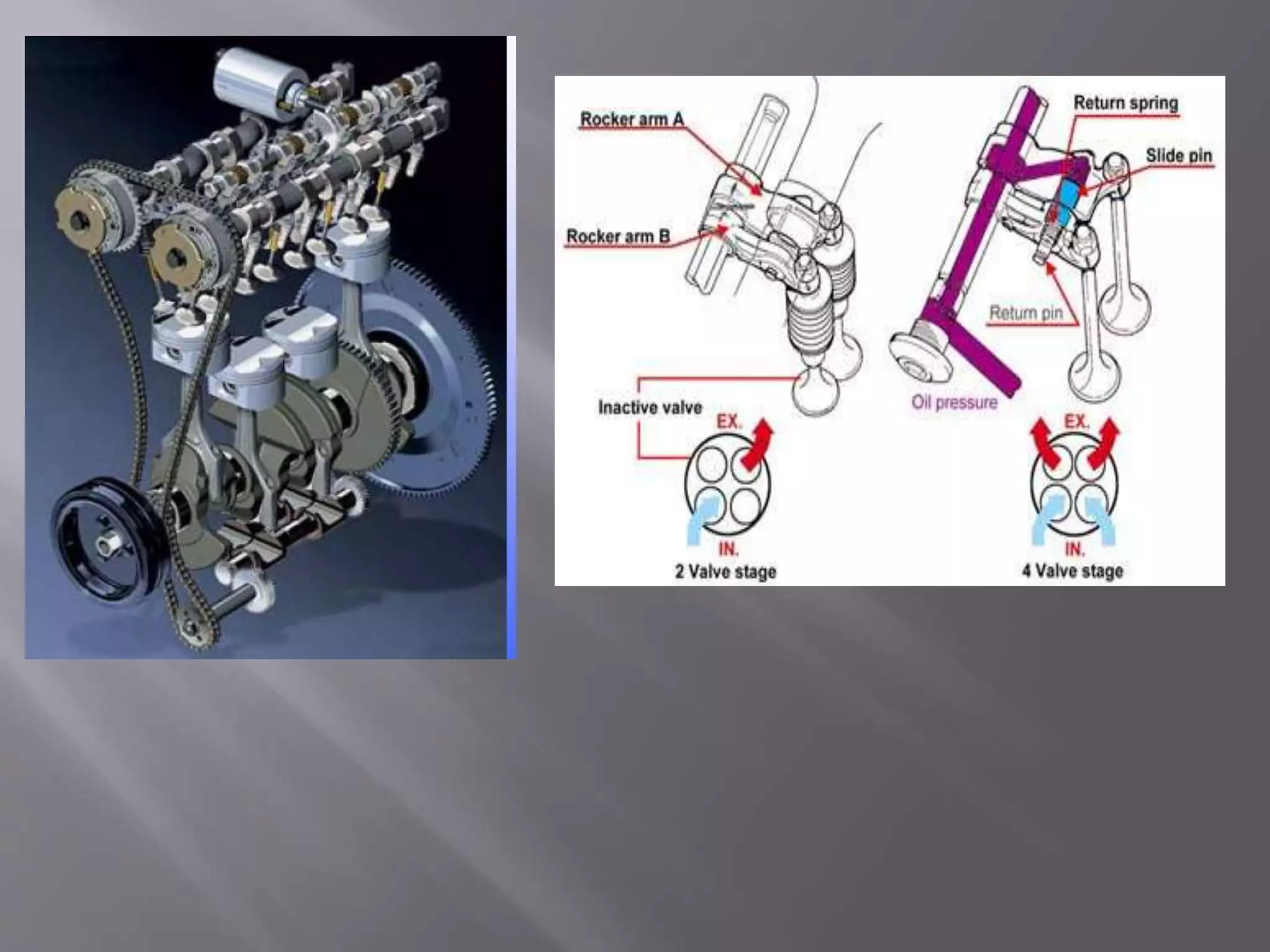

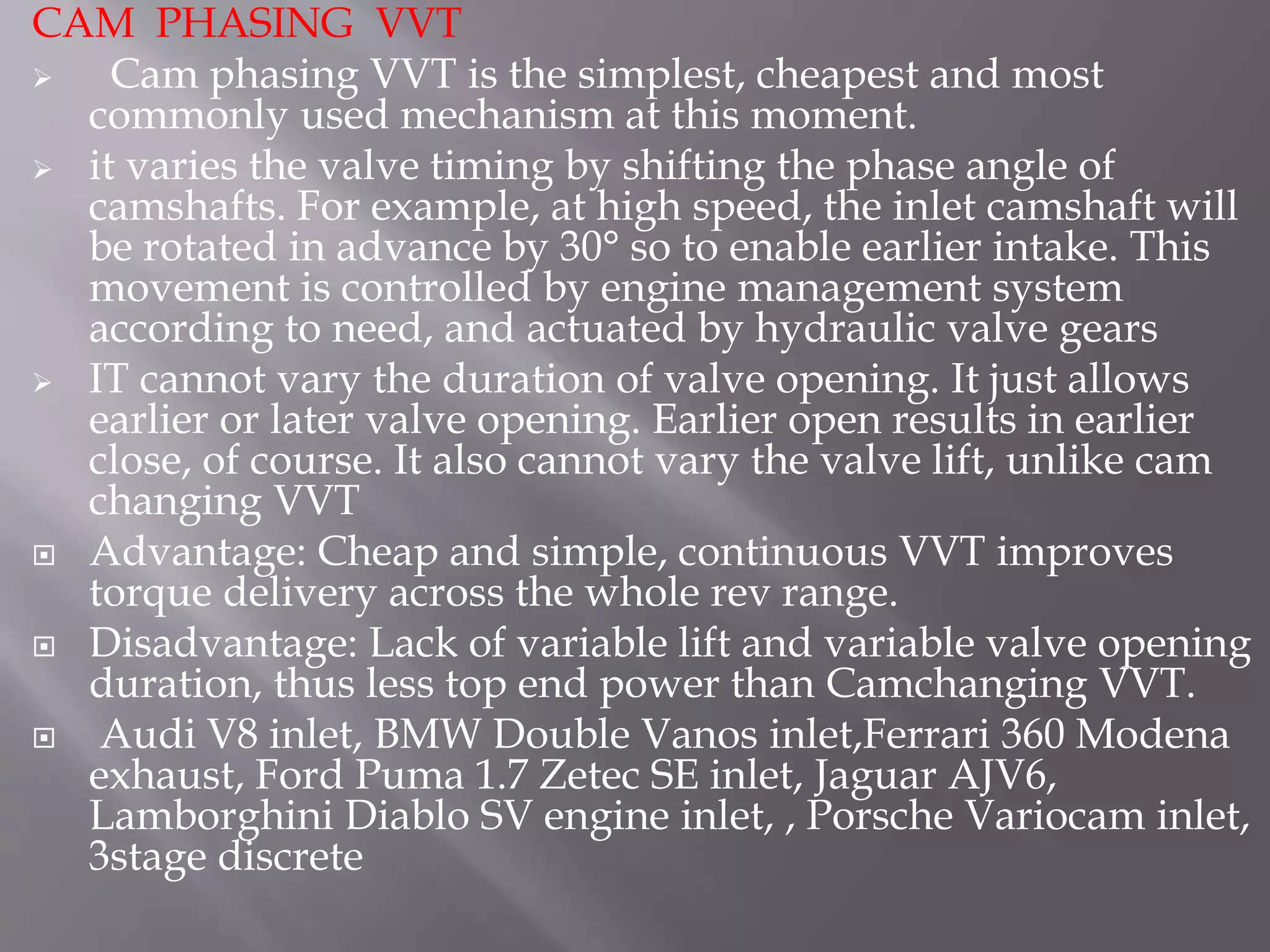

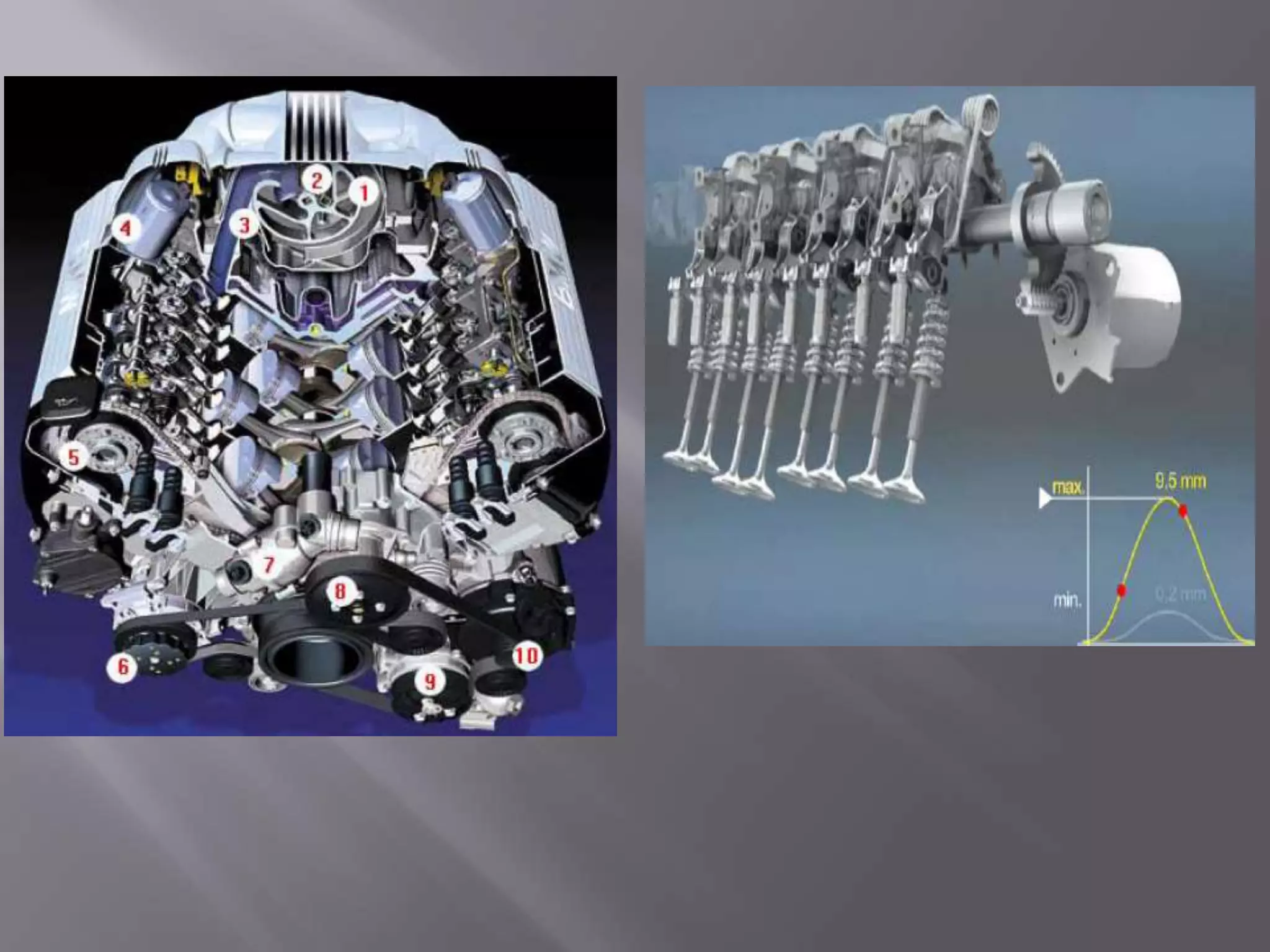

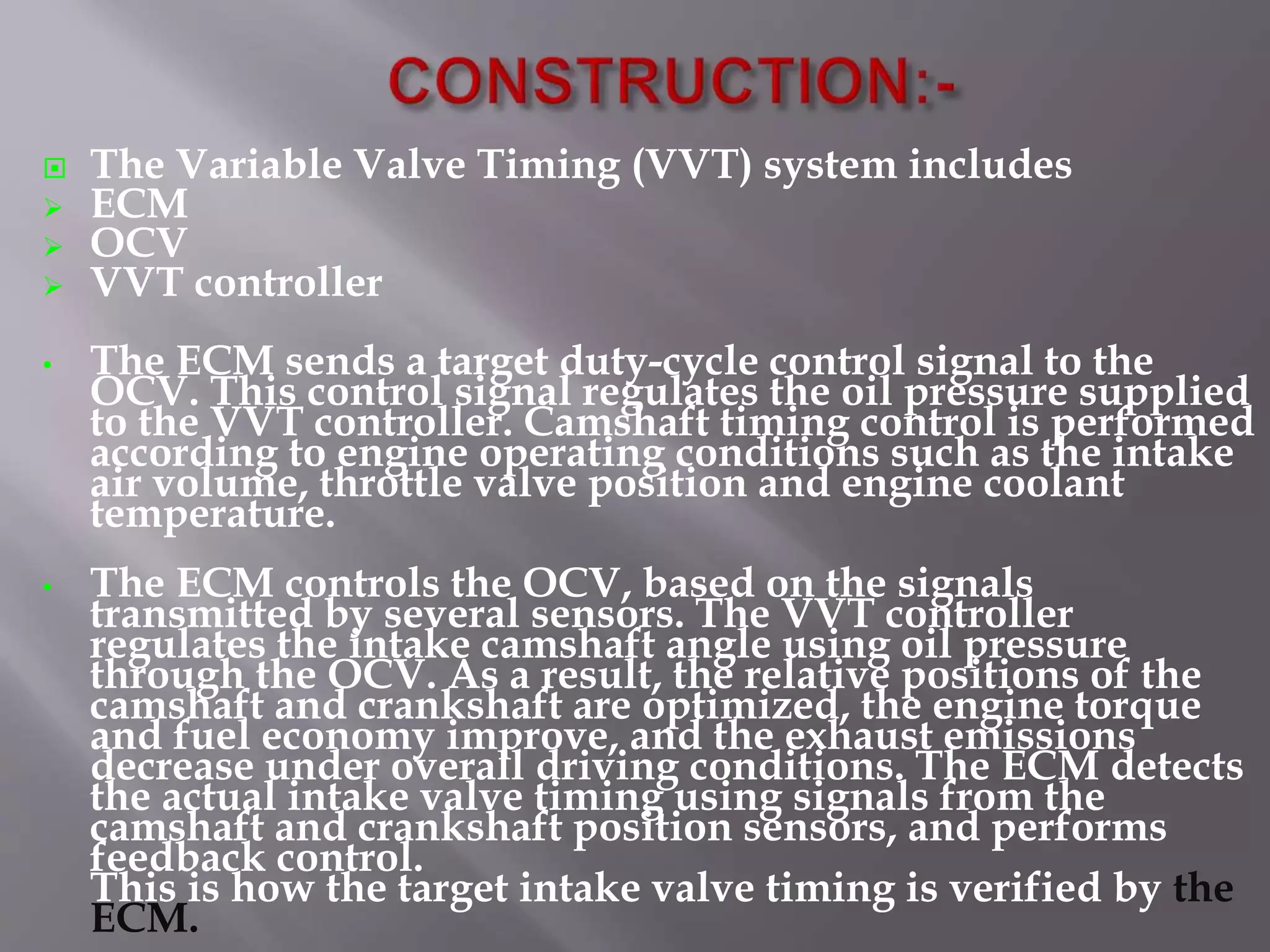

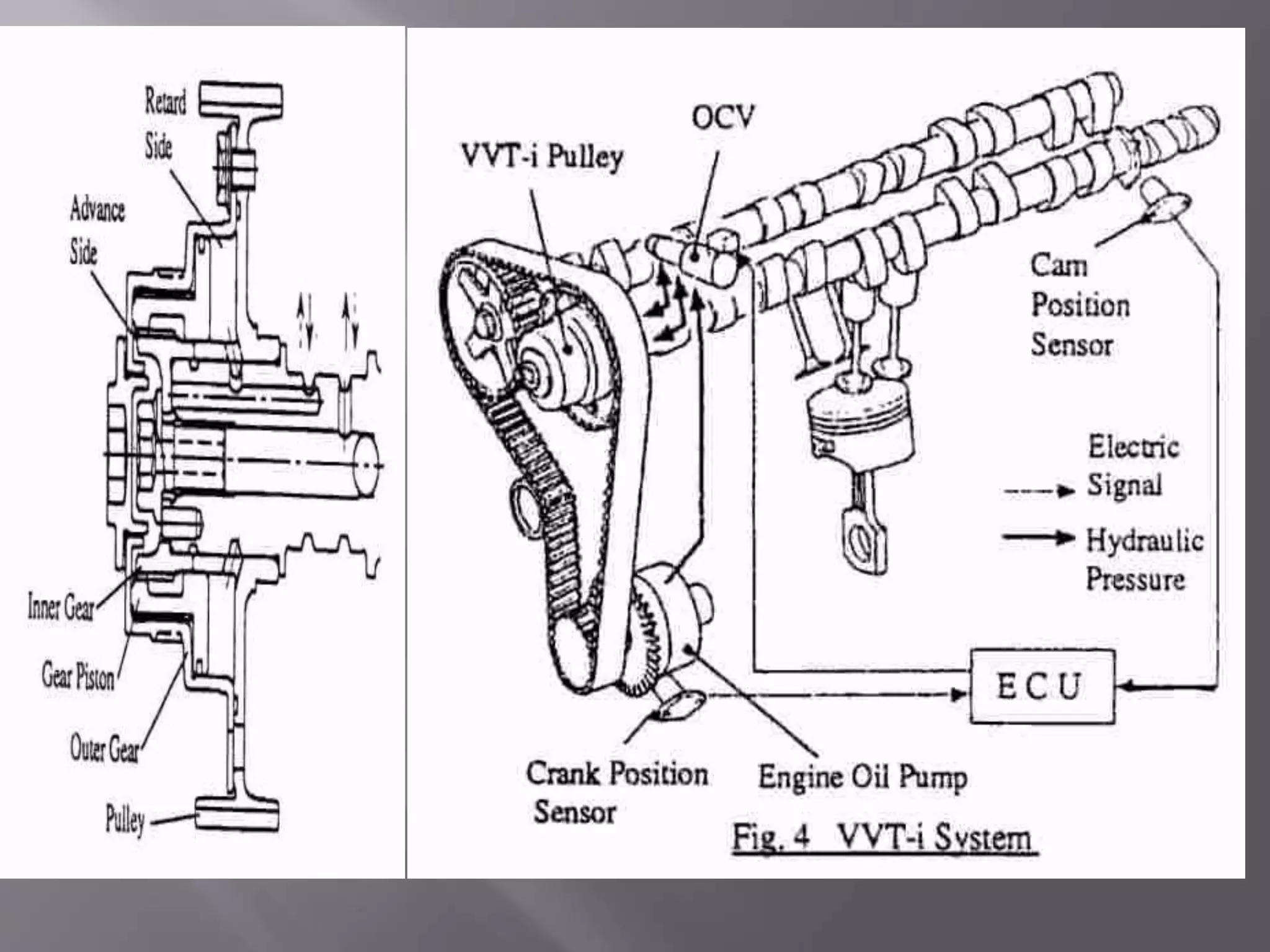

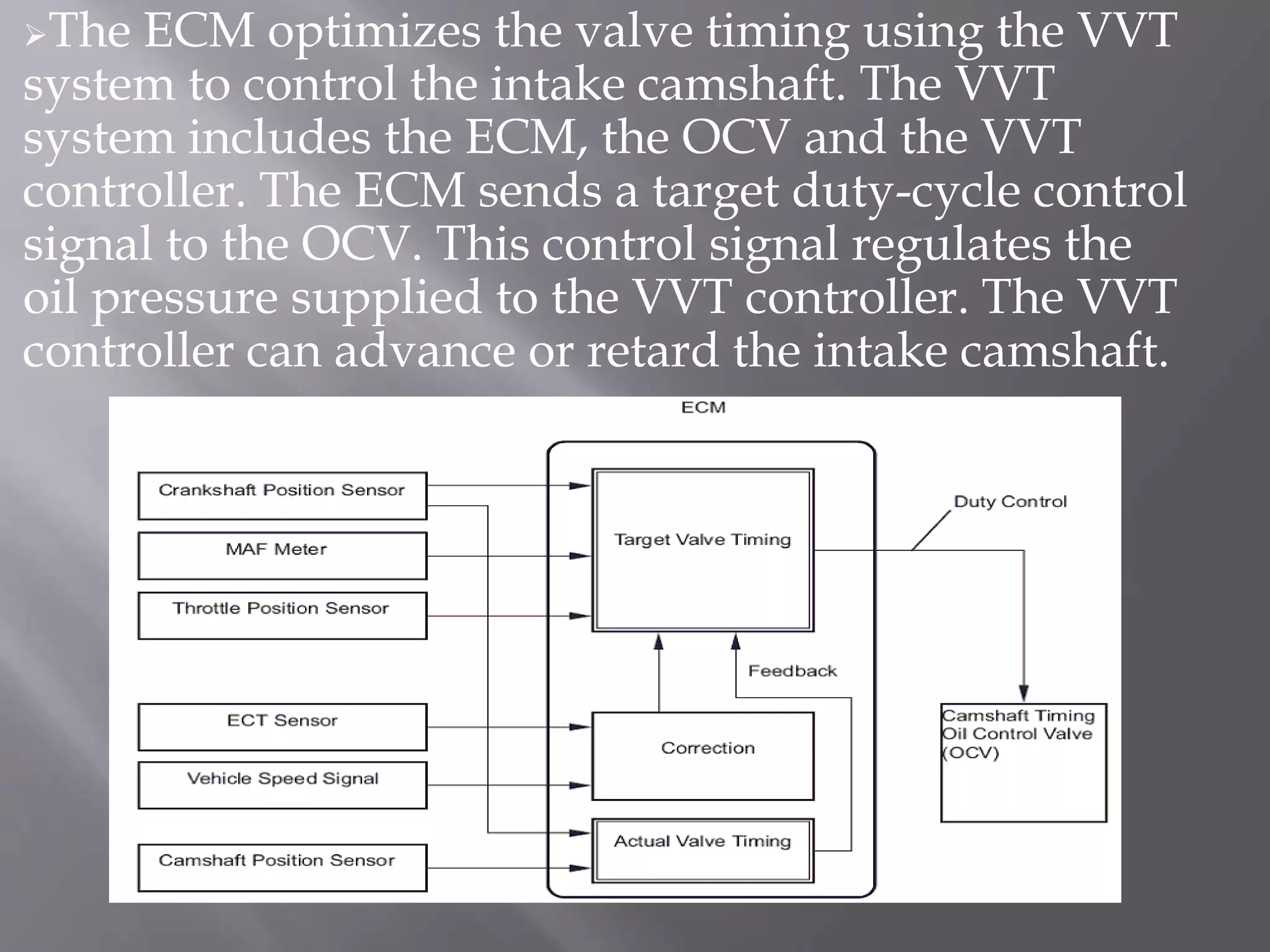

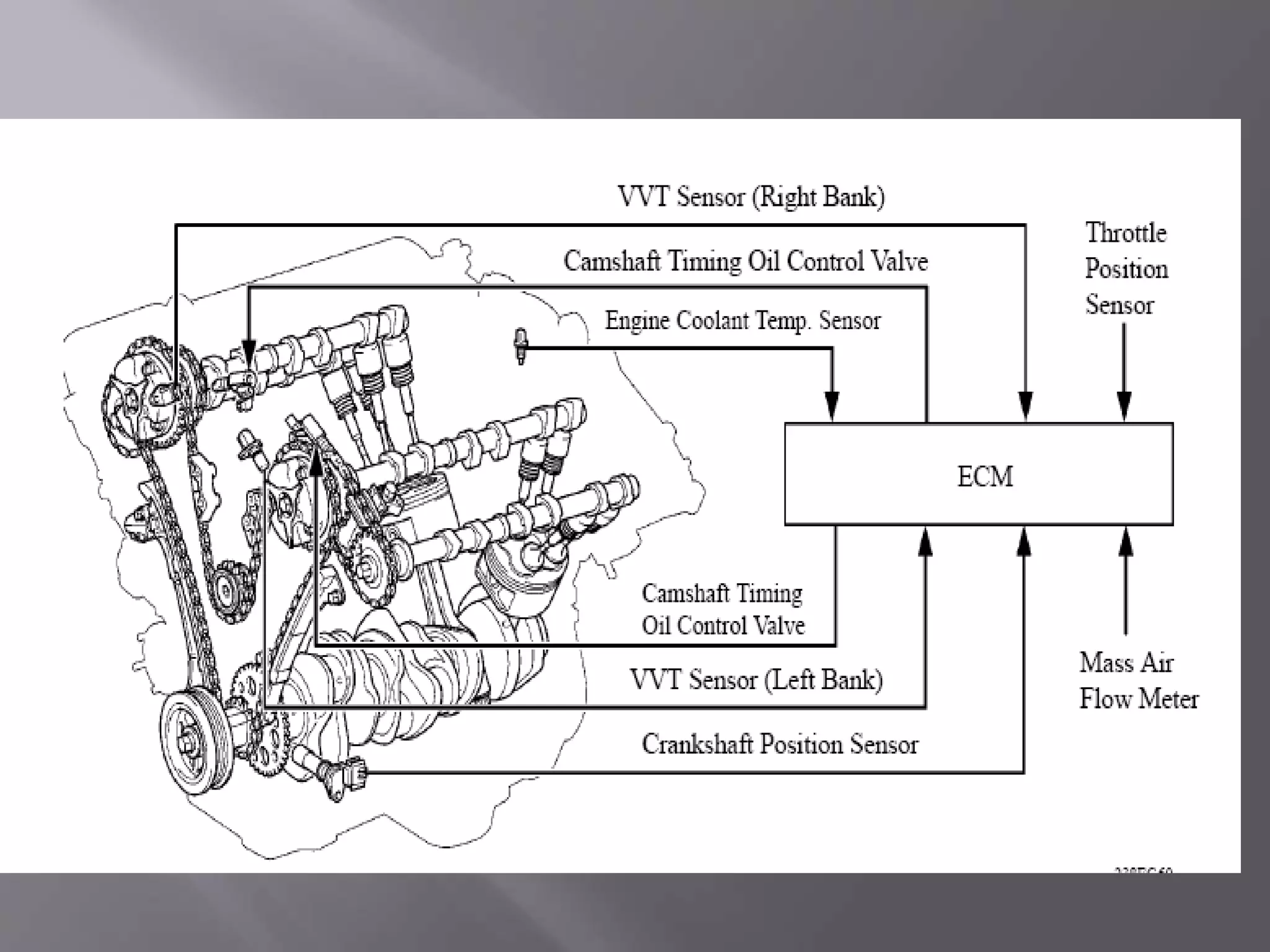

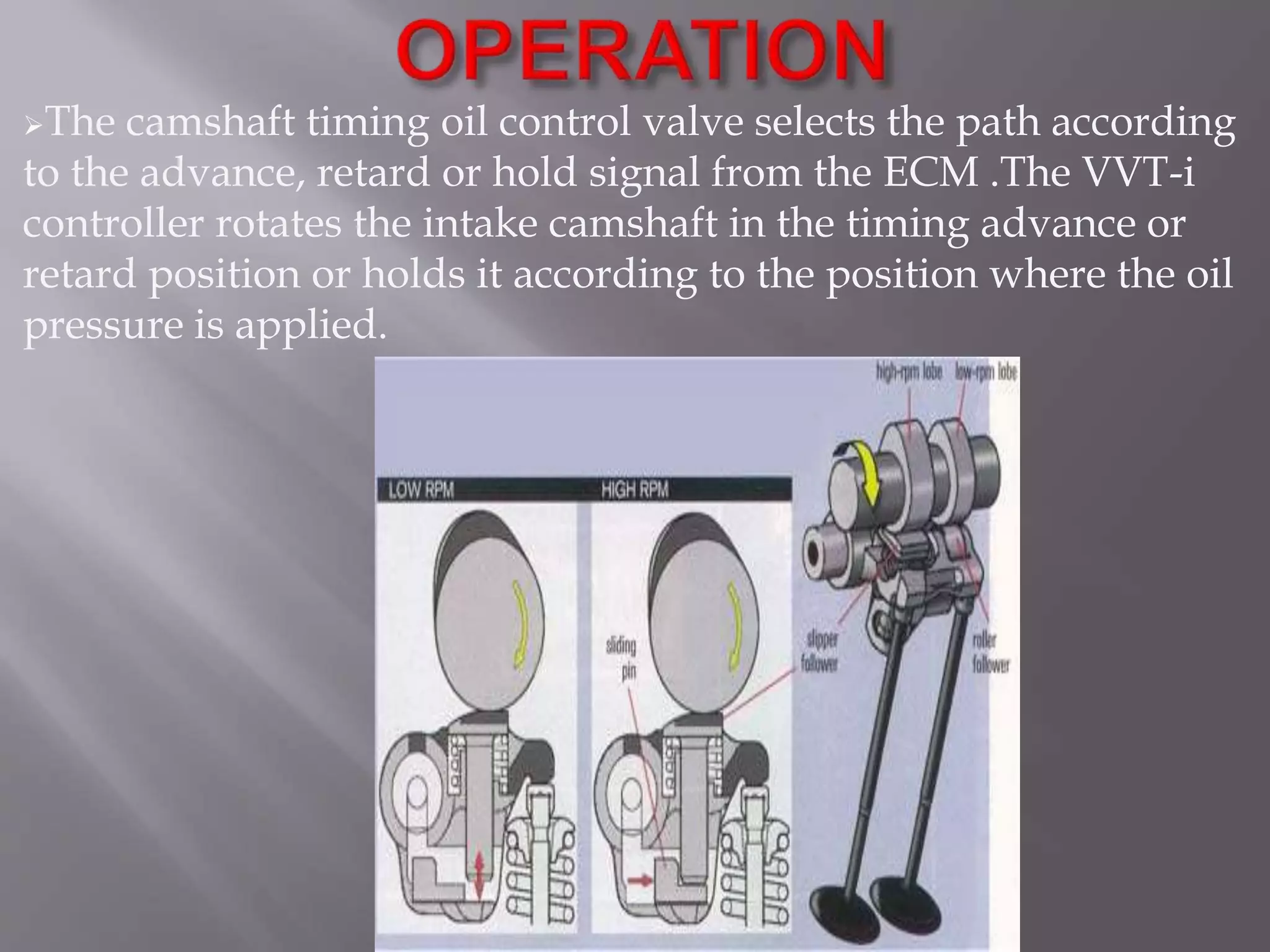

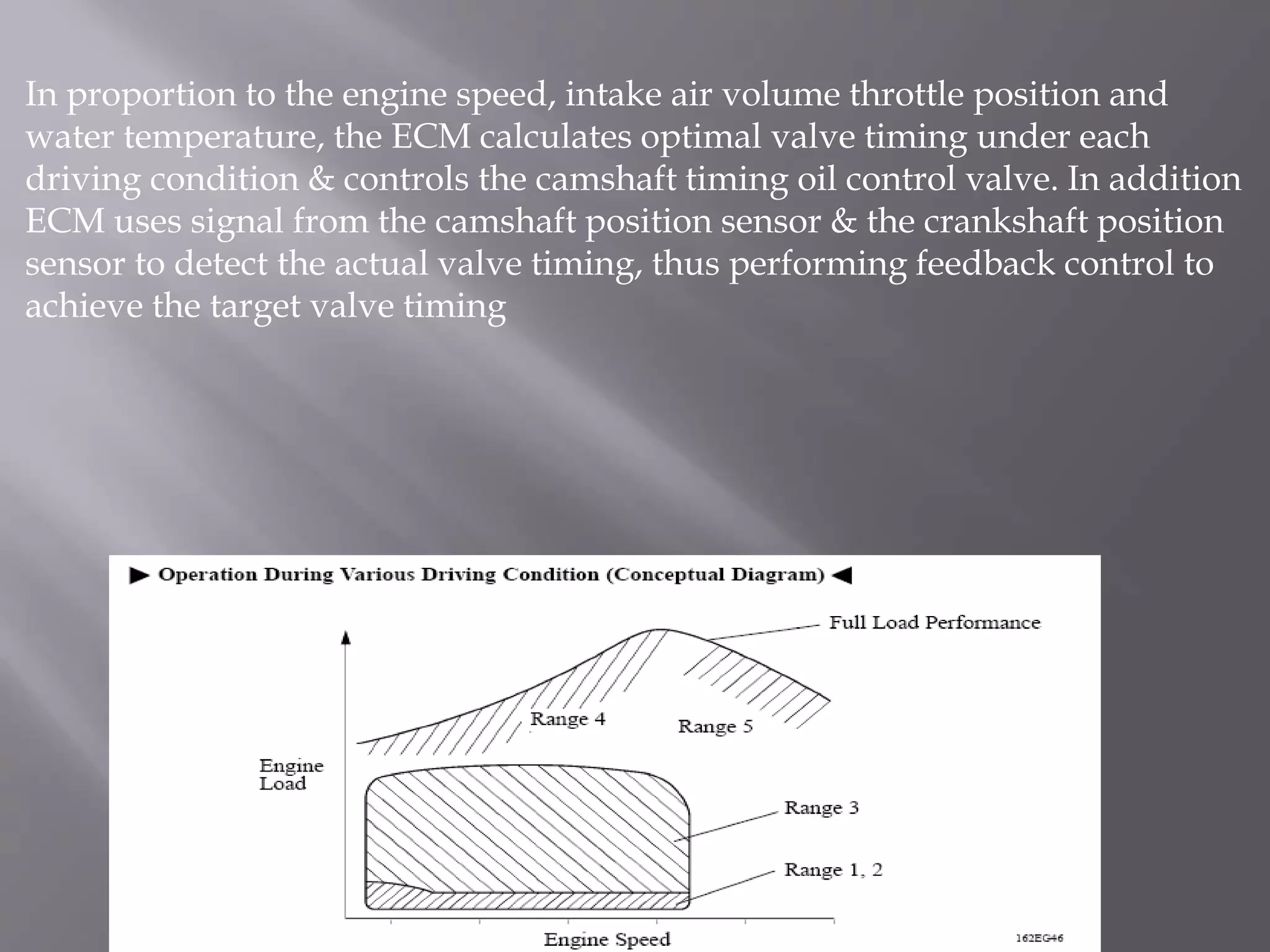

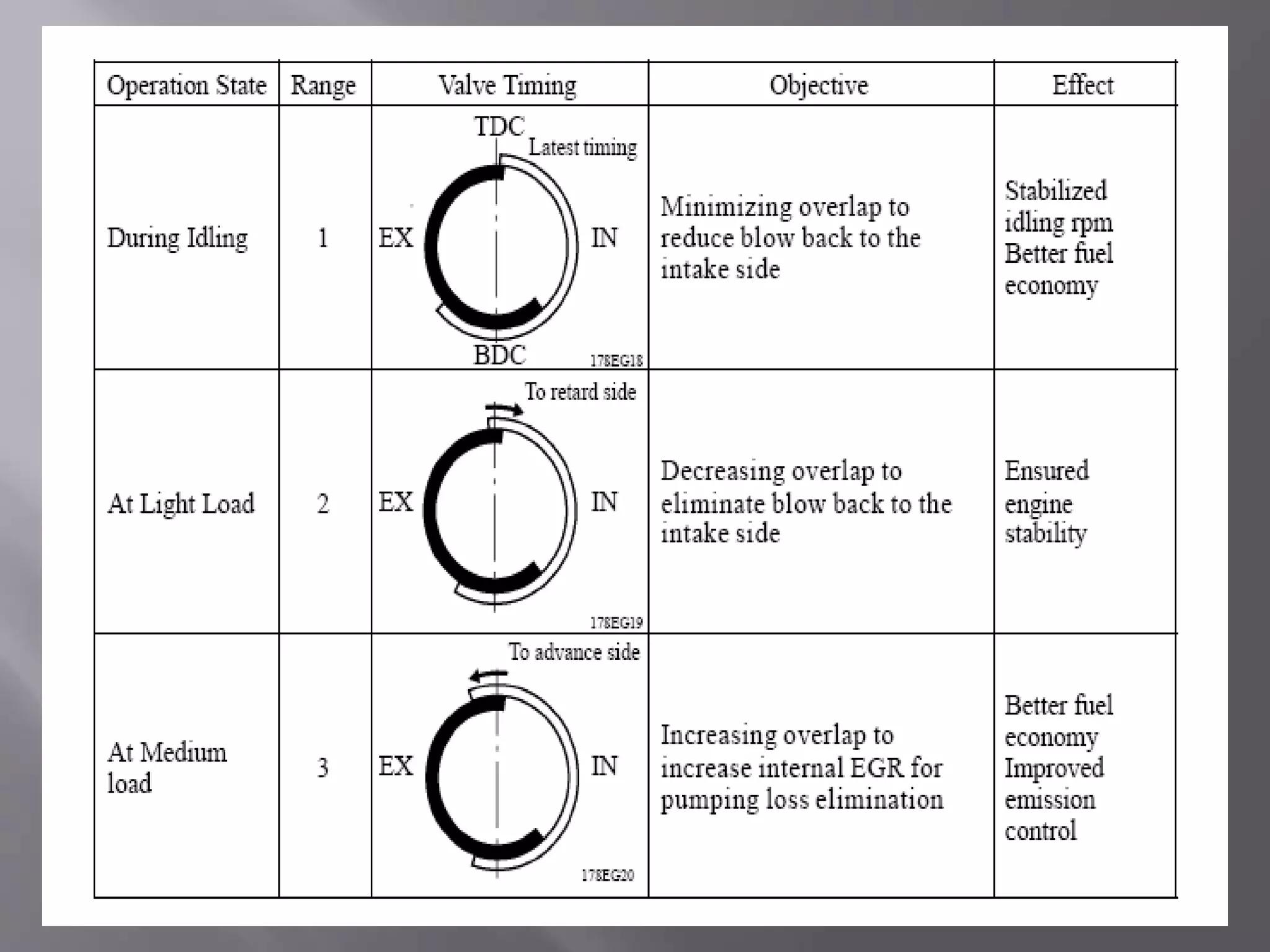

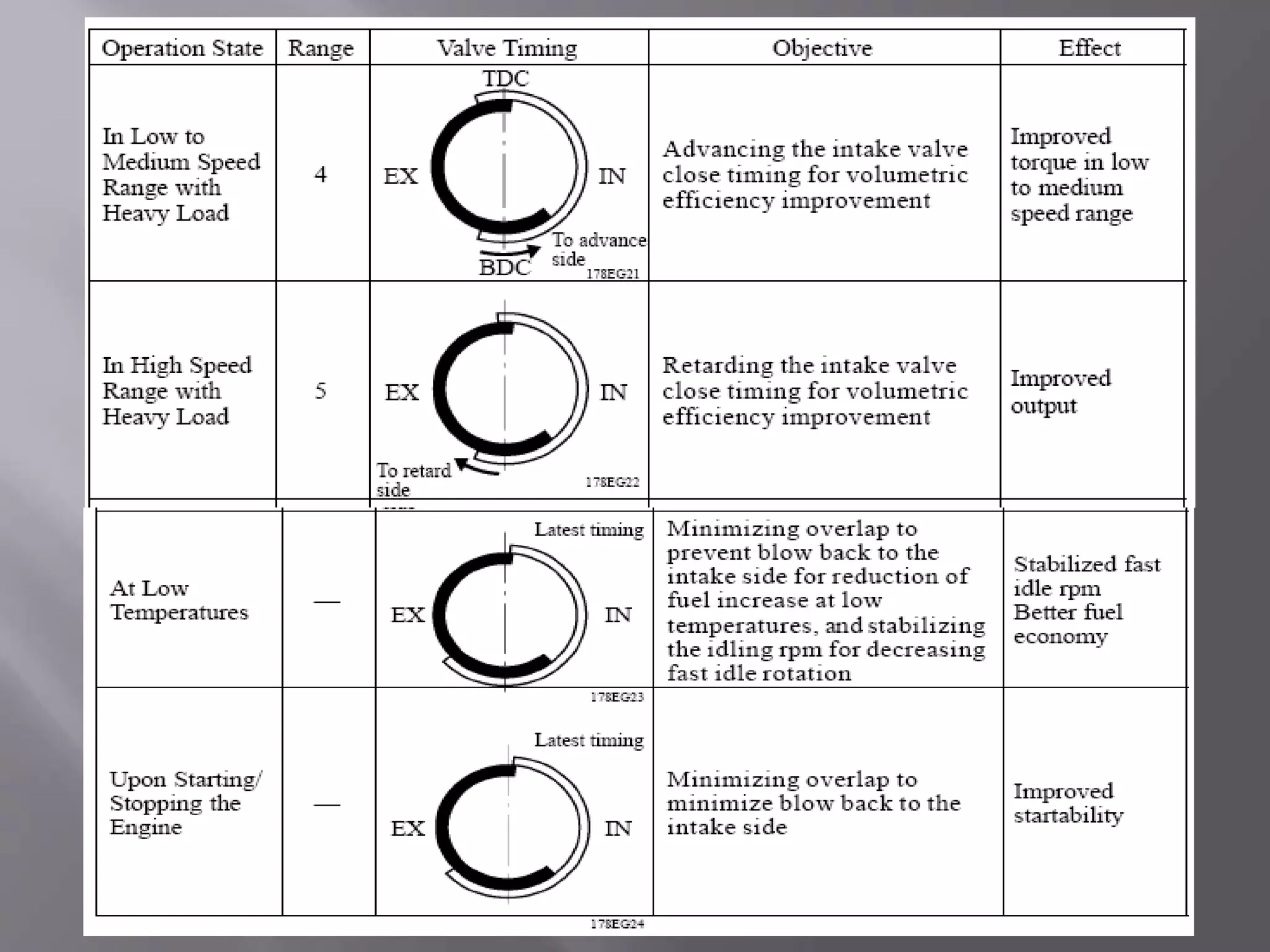

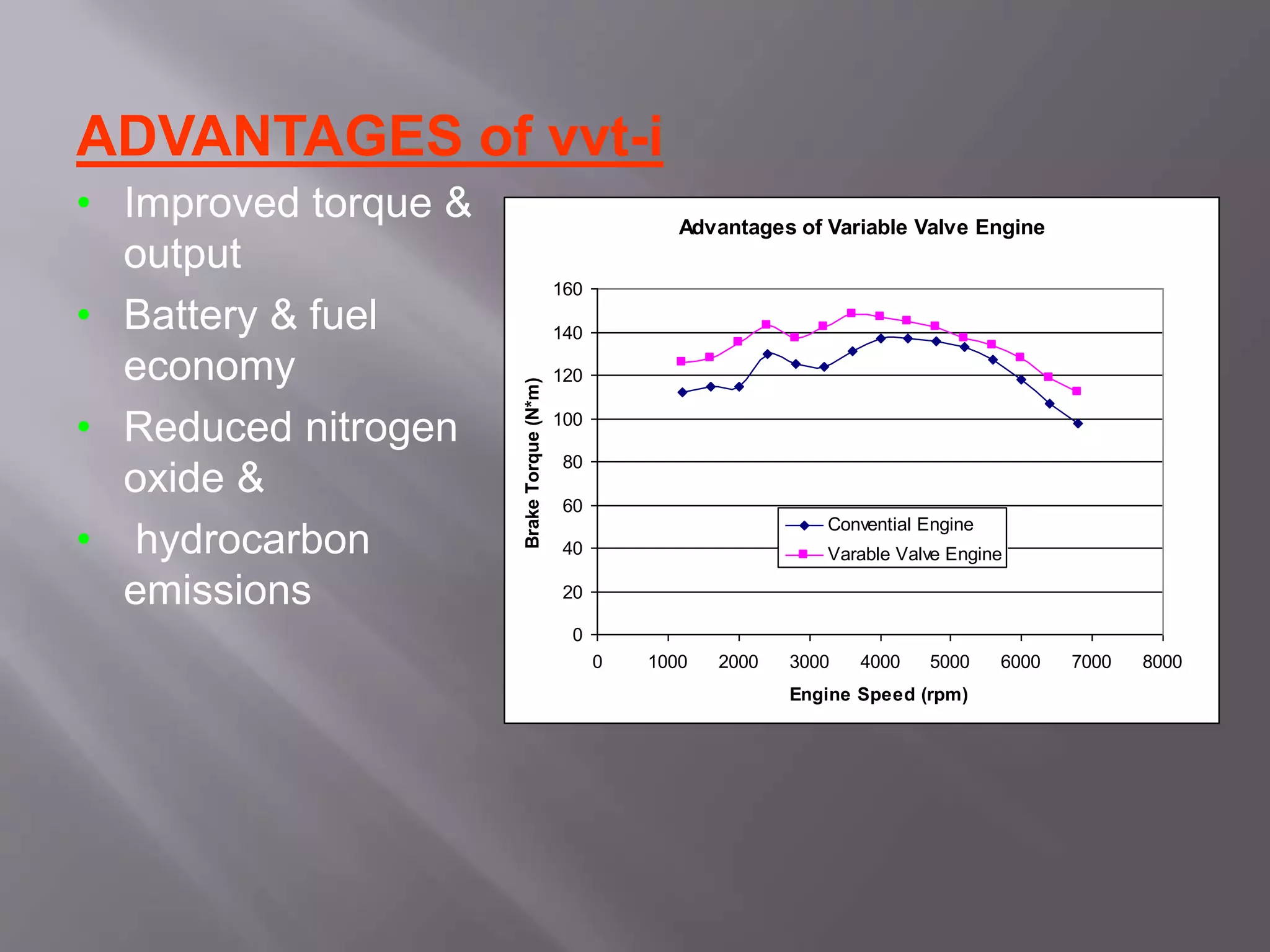

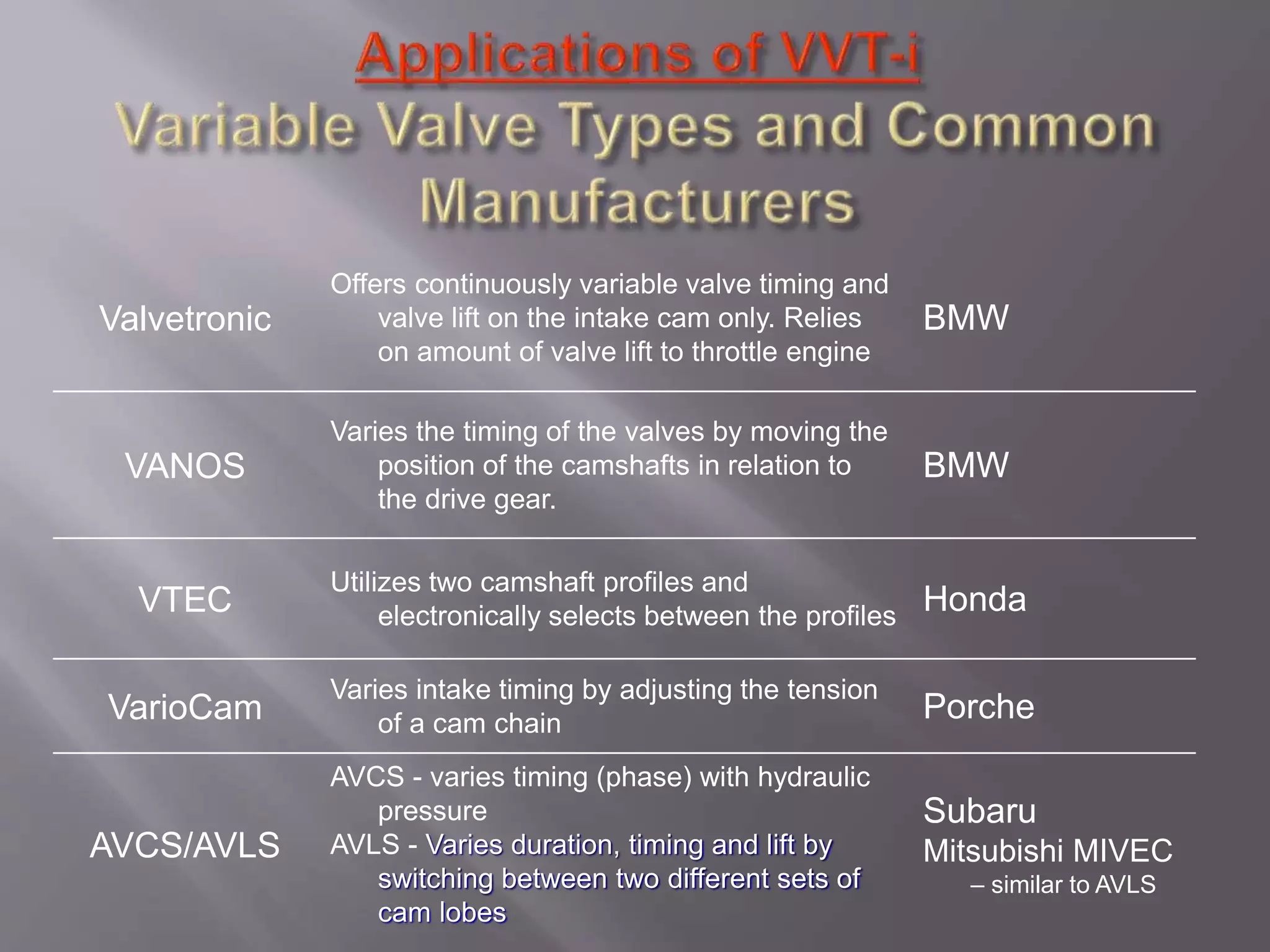

The document discusses variable valve timing (VVT) technology in engines, detailing its role in optimizing engine output, power, and torque through two main types: cam changing VVT and cam phasing VVT. Cam changing VVT uses different cam profiles to adapt to engine loads and speeds, while cam phasing VVT adjusts the timing of valve openings without changing valve lift. The VVT system enhances torque, fuel efficiency, and reduces emissions, with various examples and automotive applications provided.