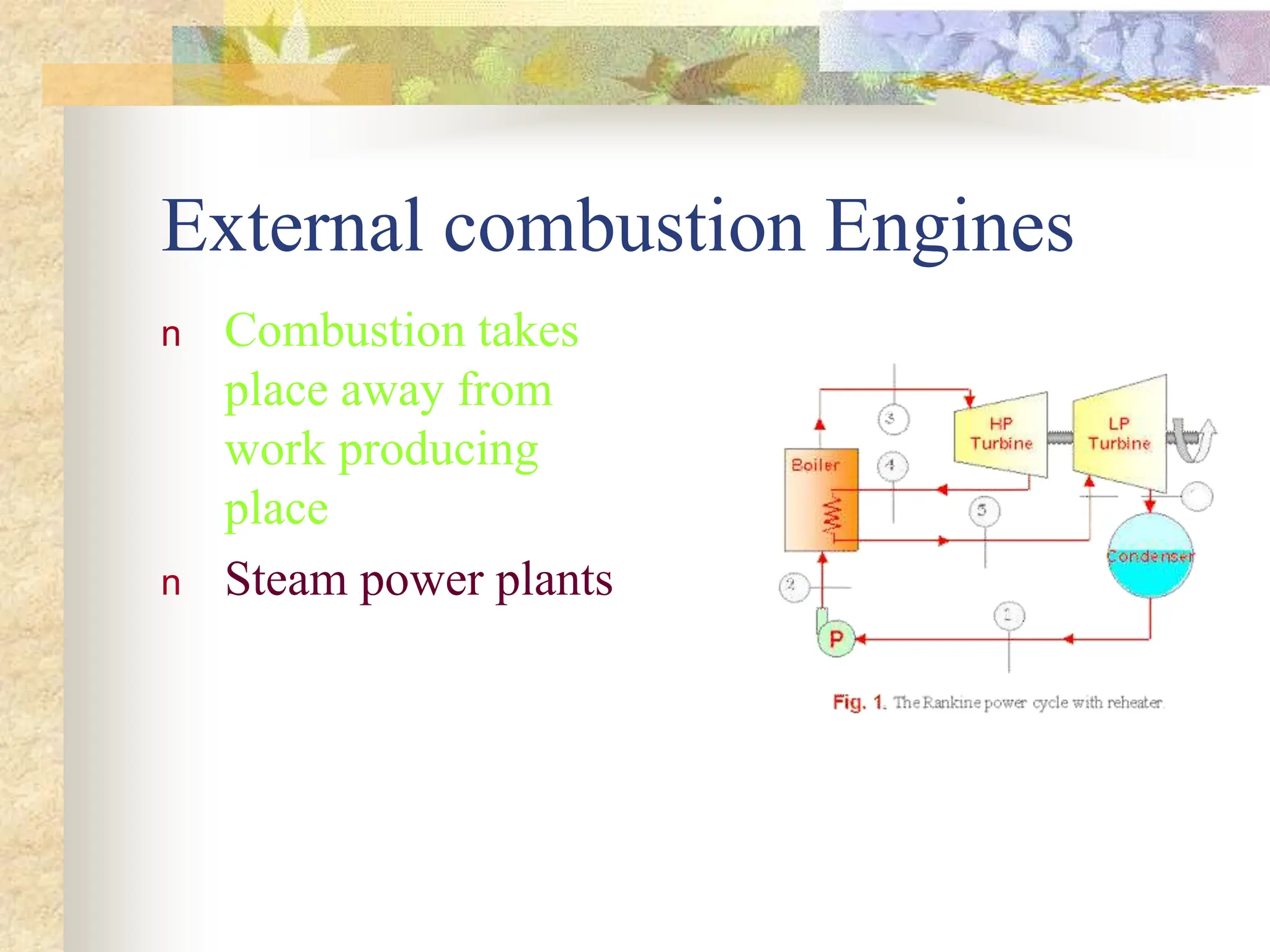

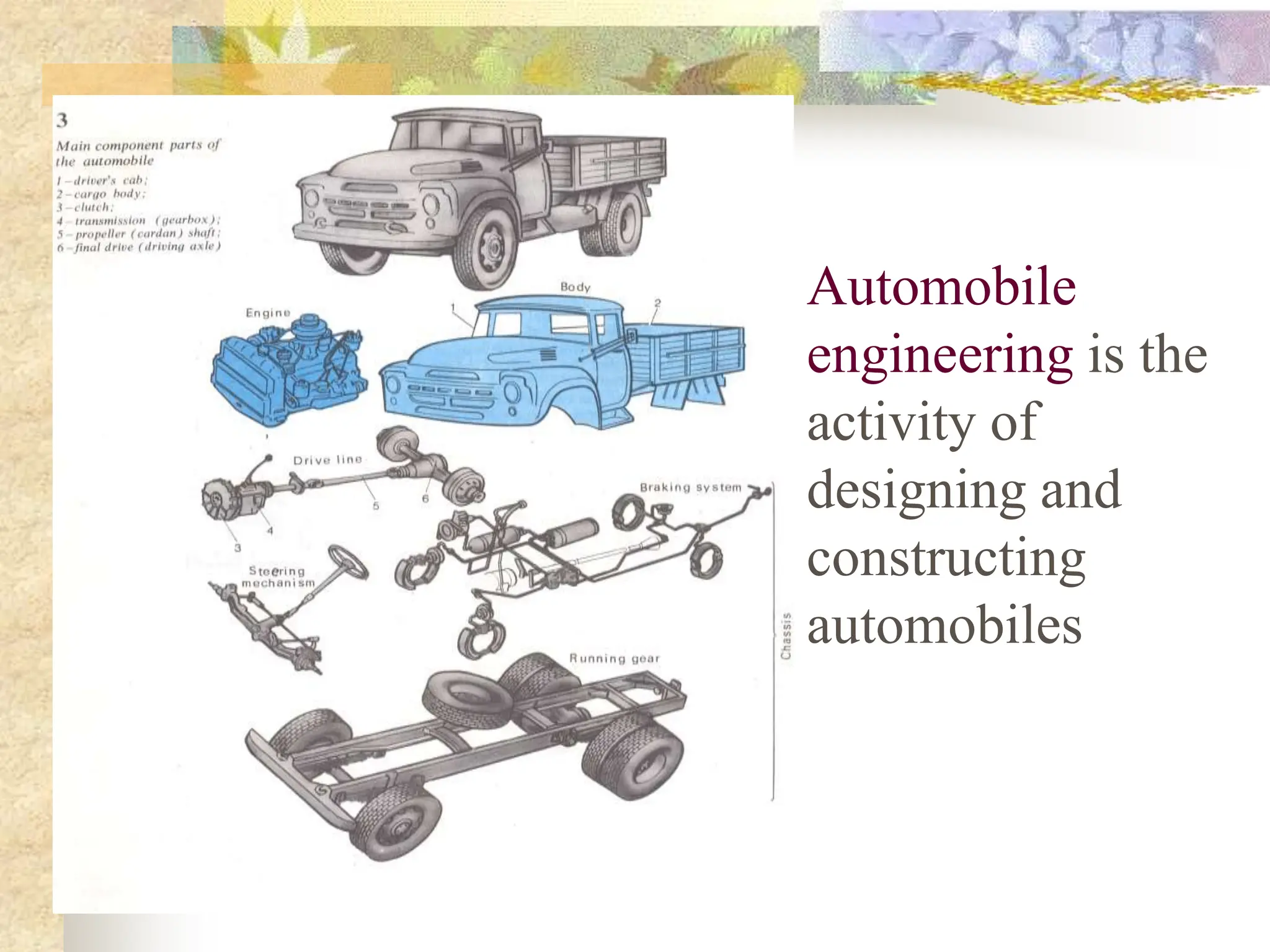

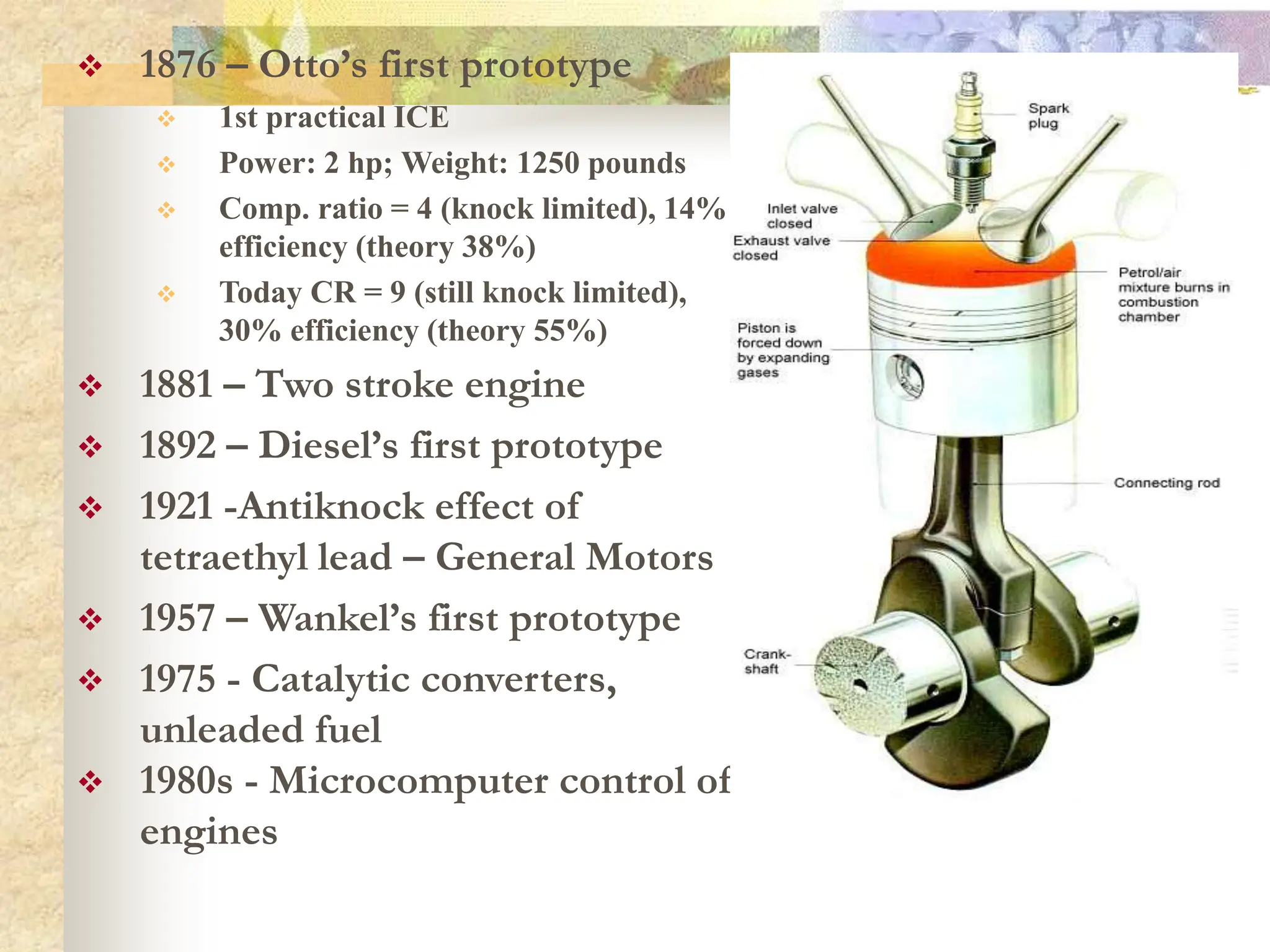

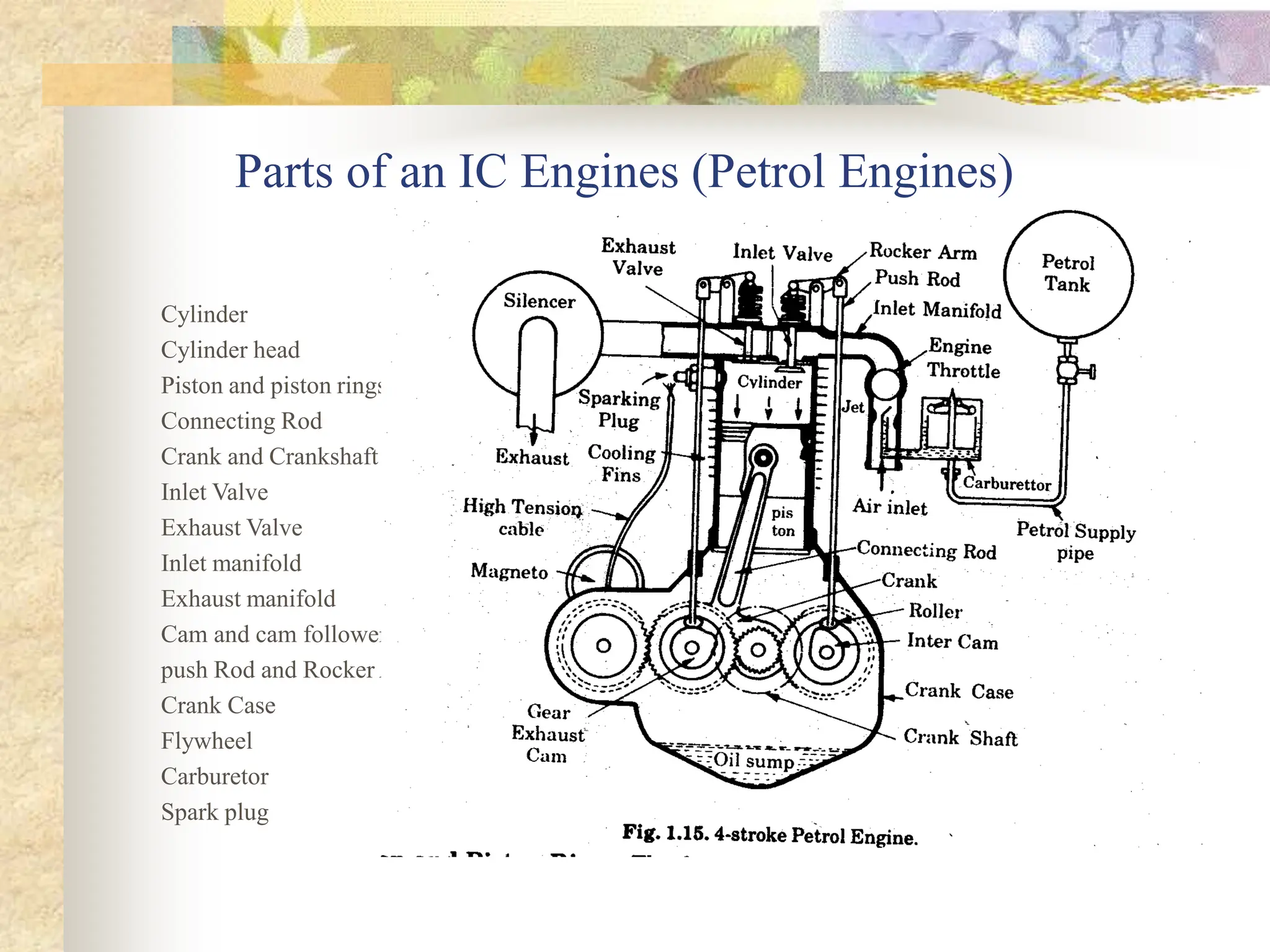

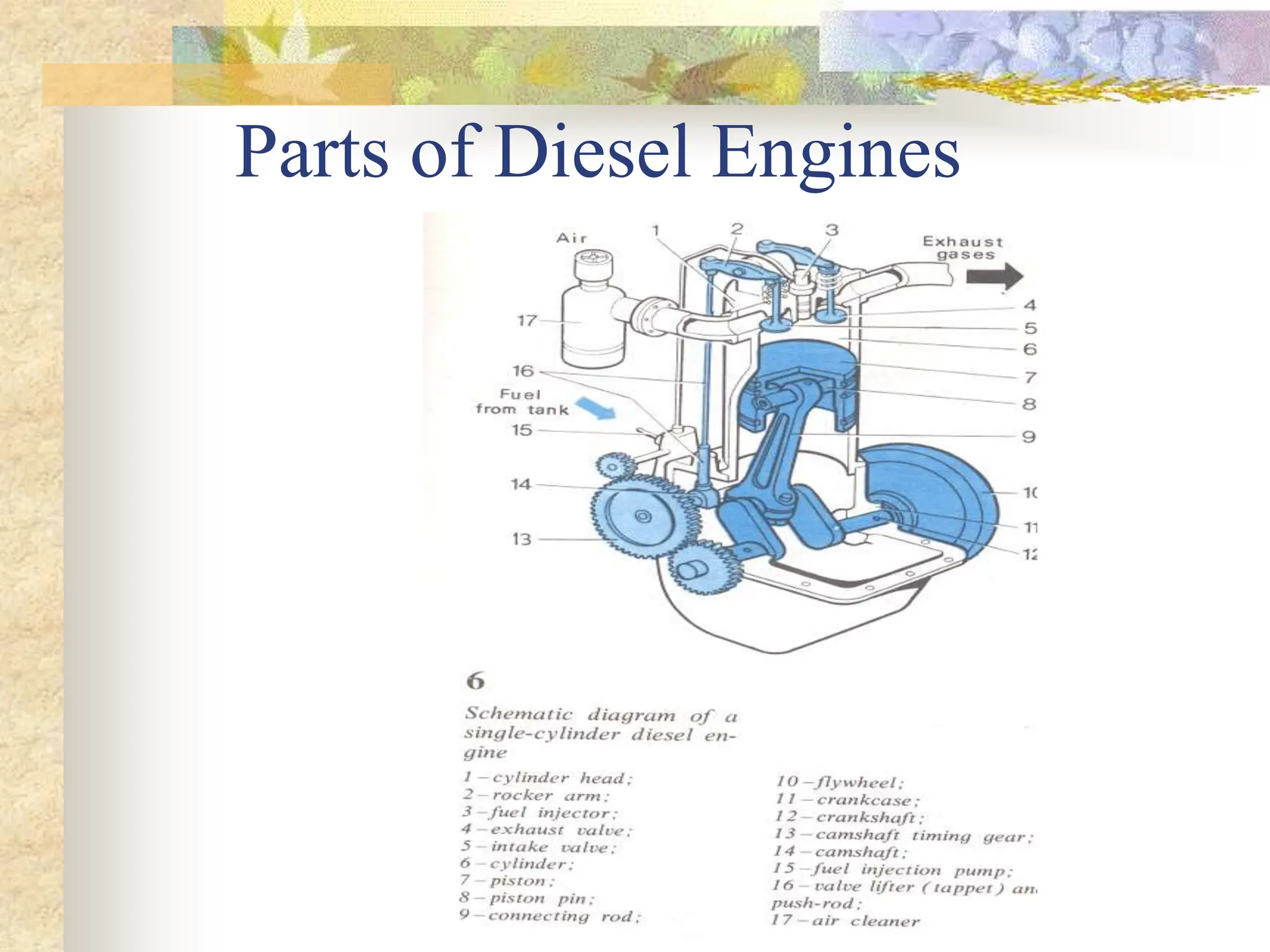

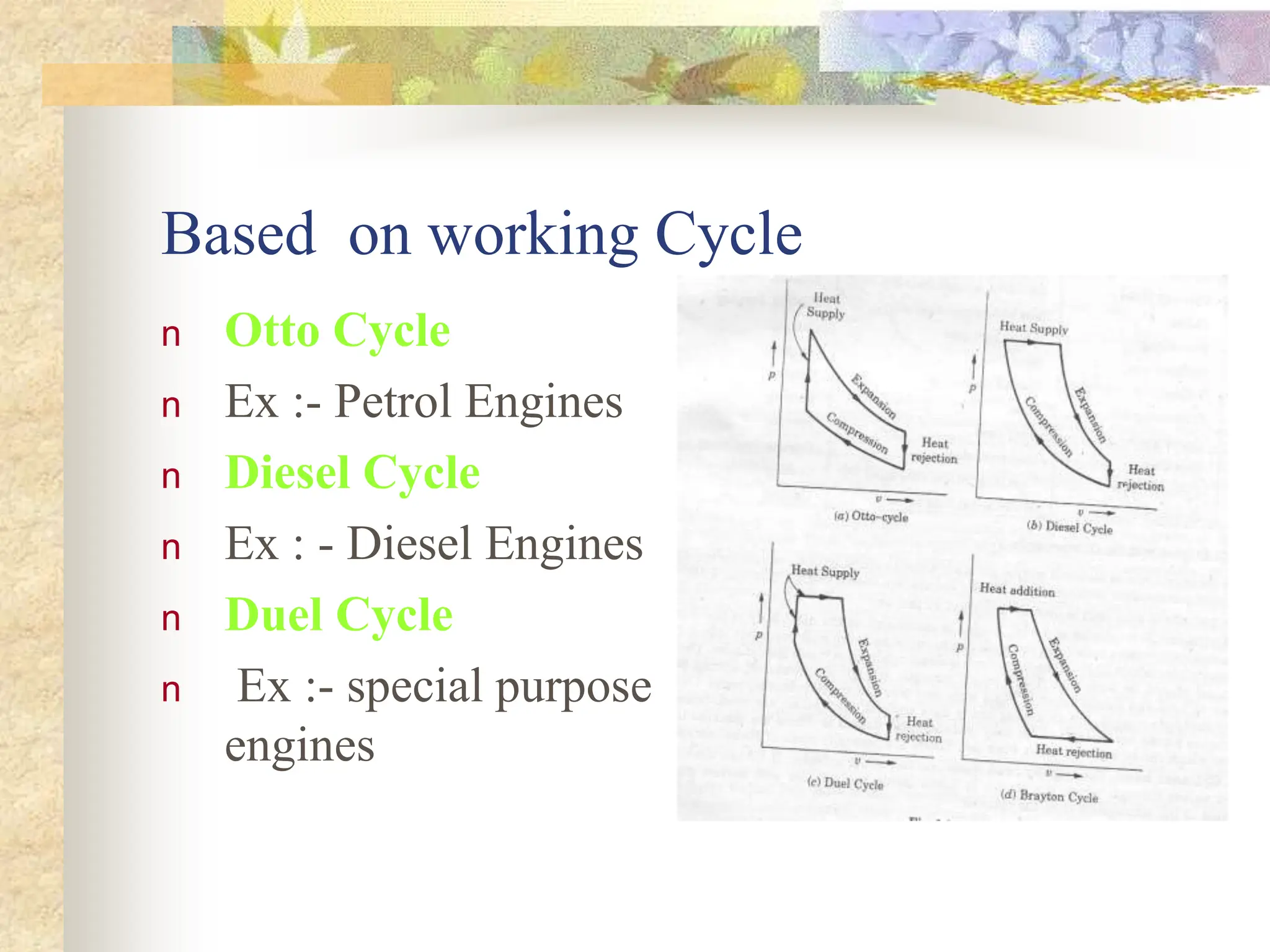

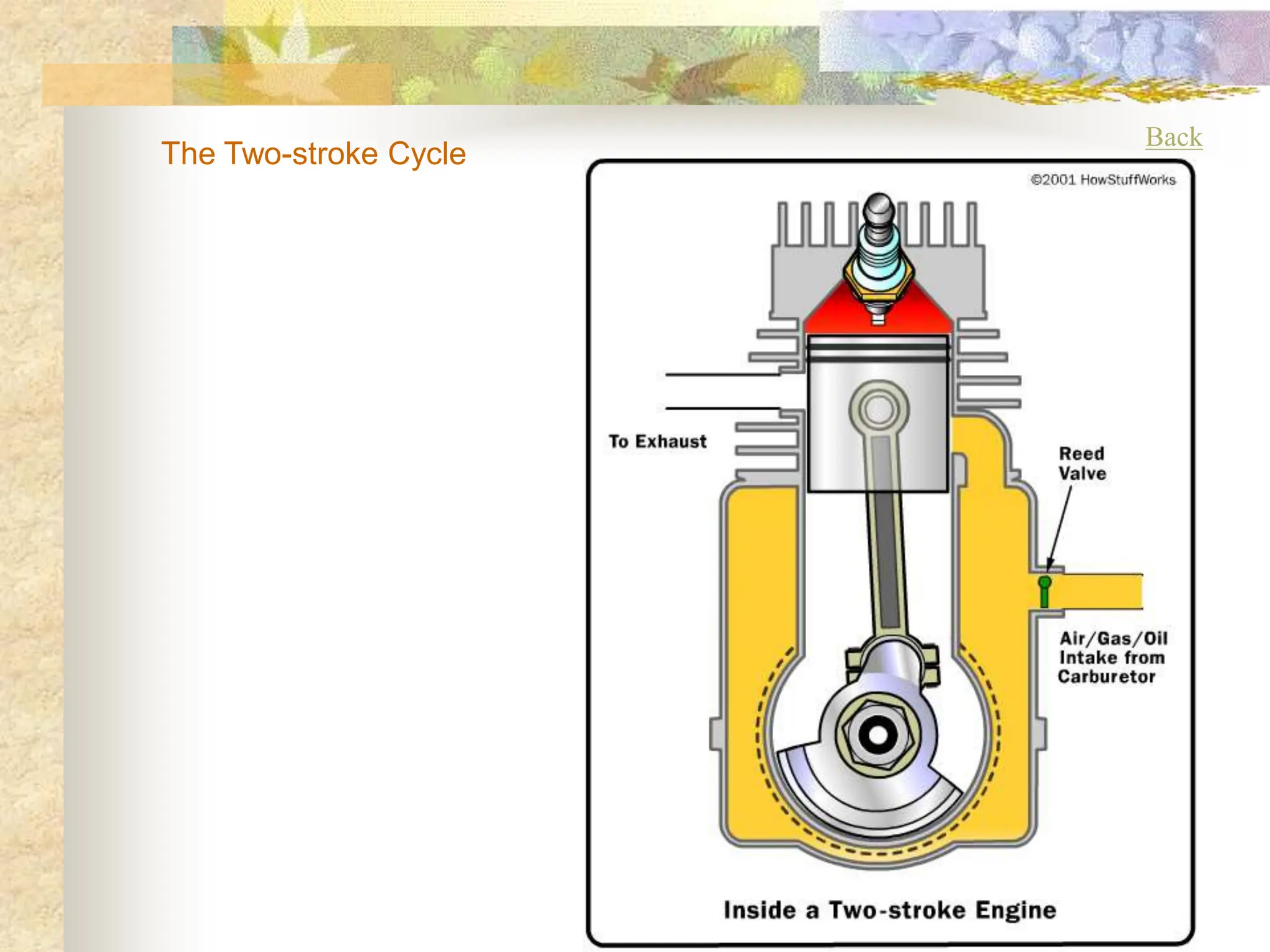

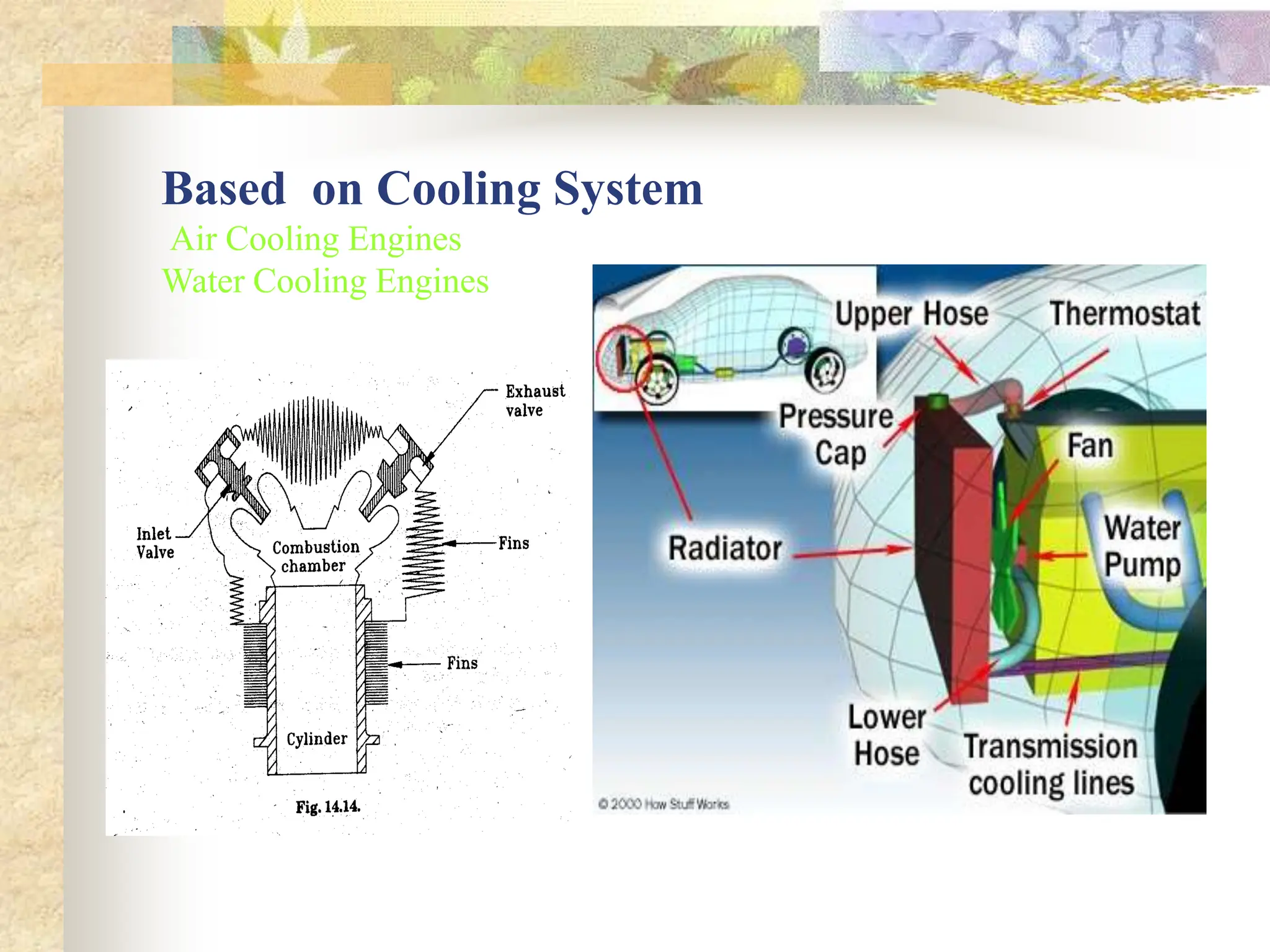

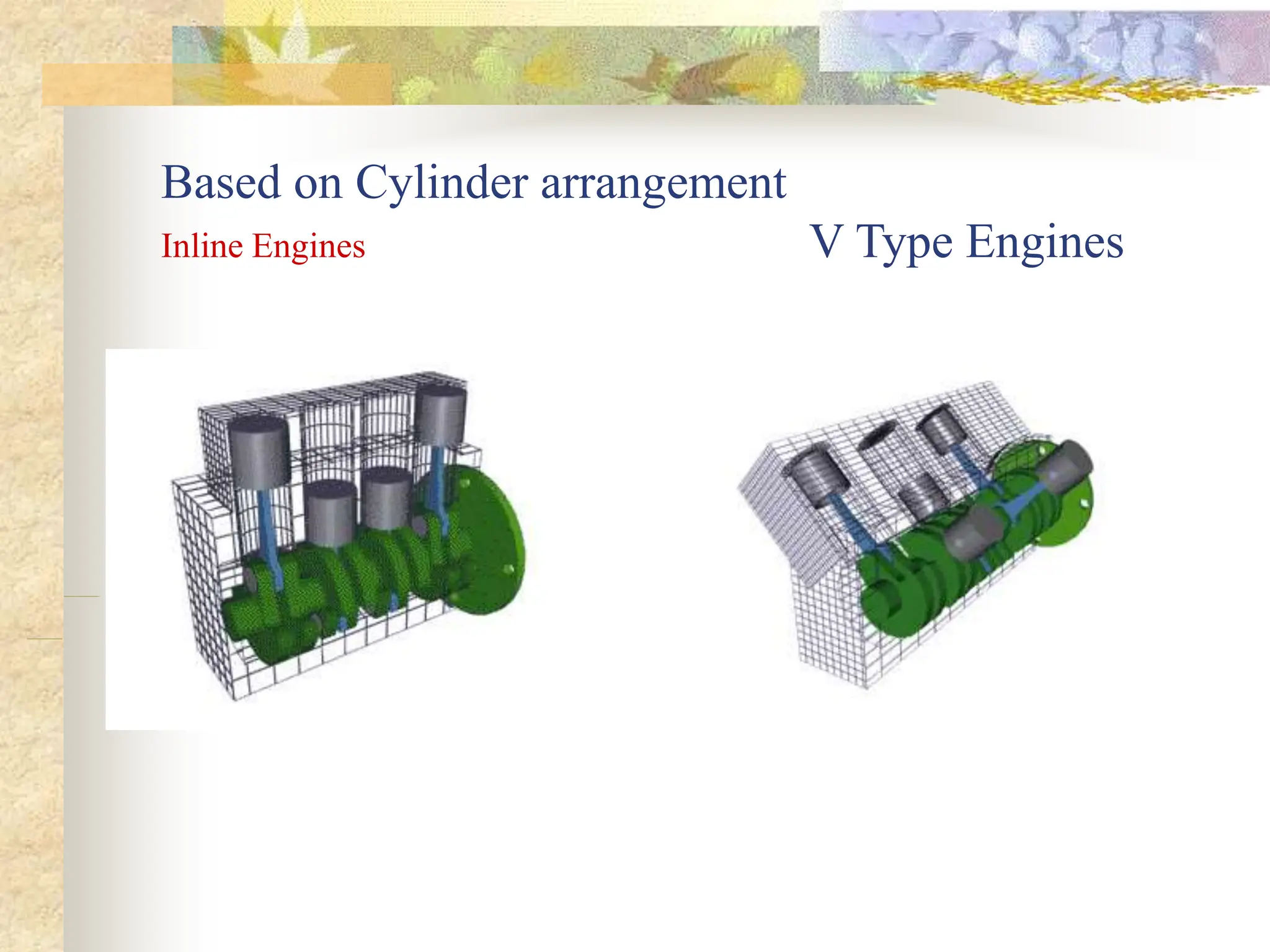

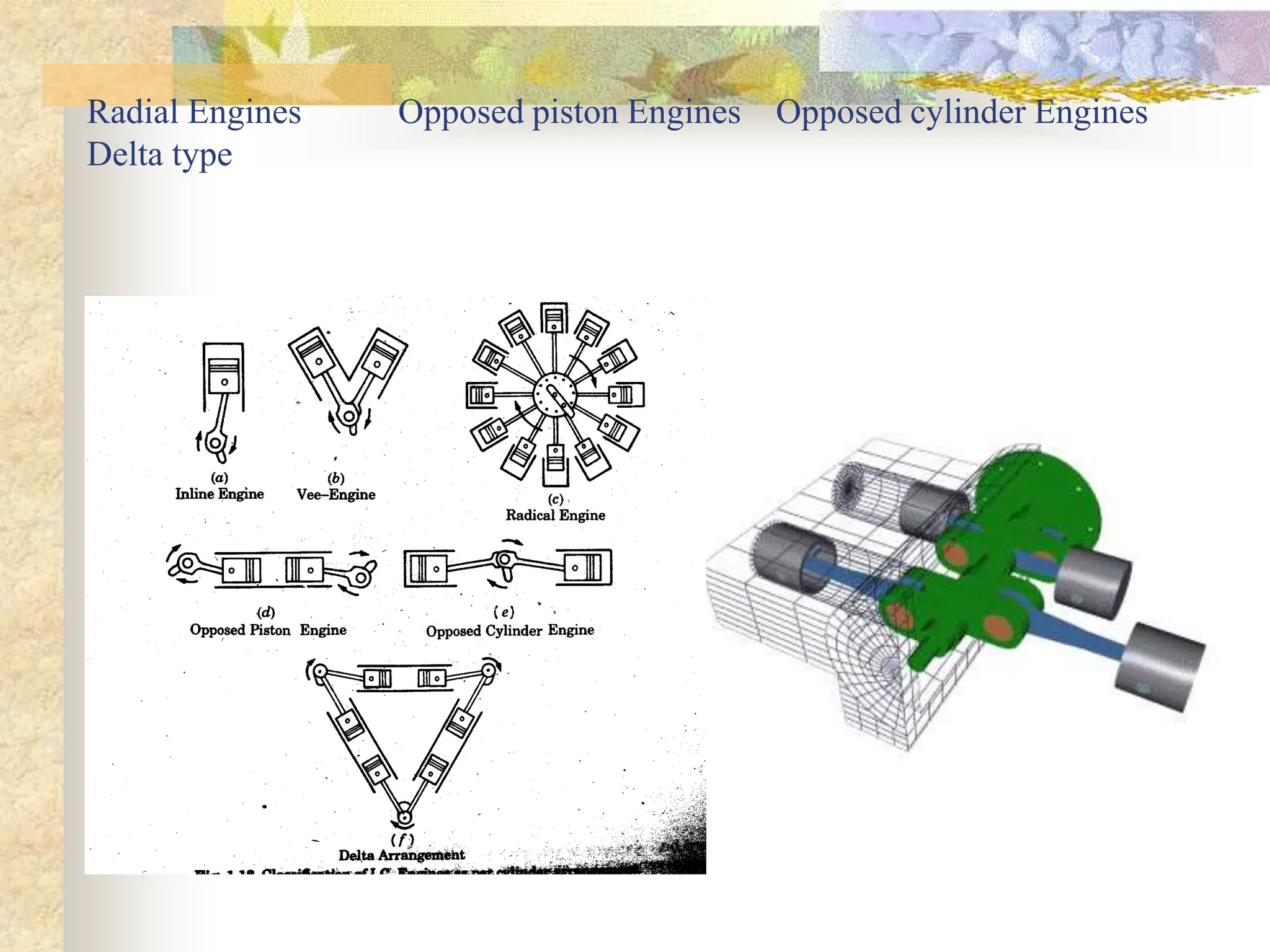

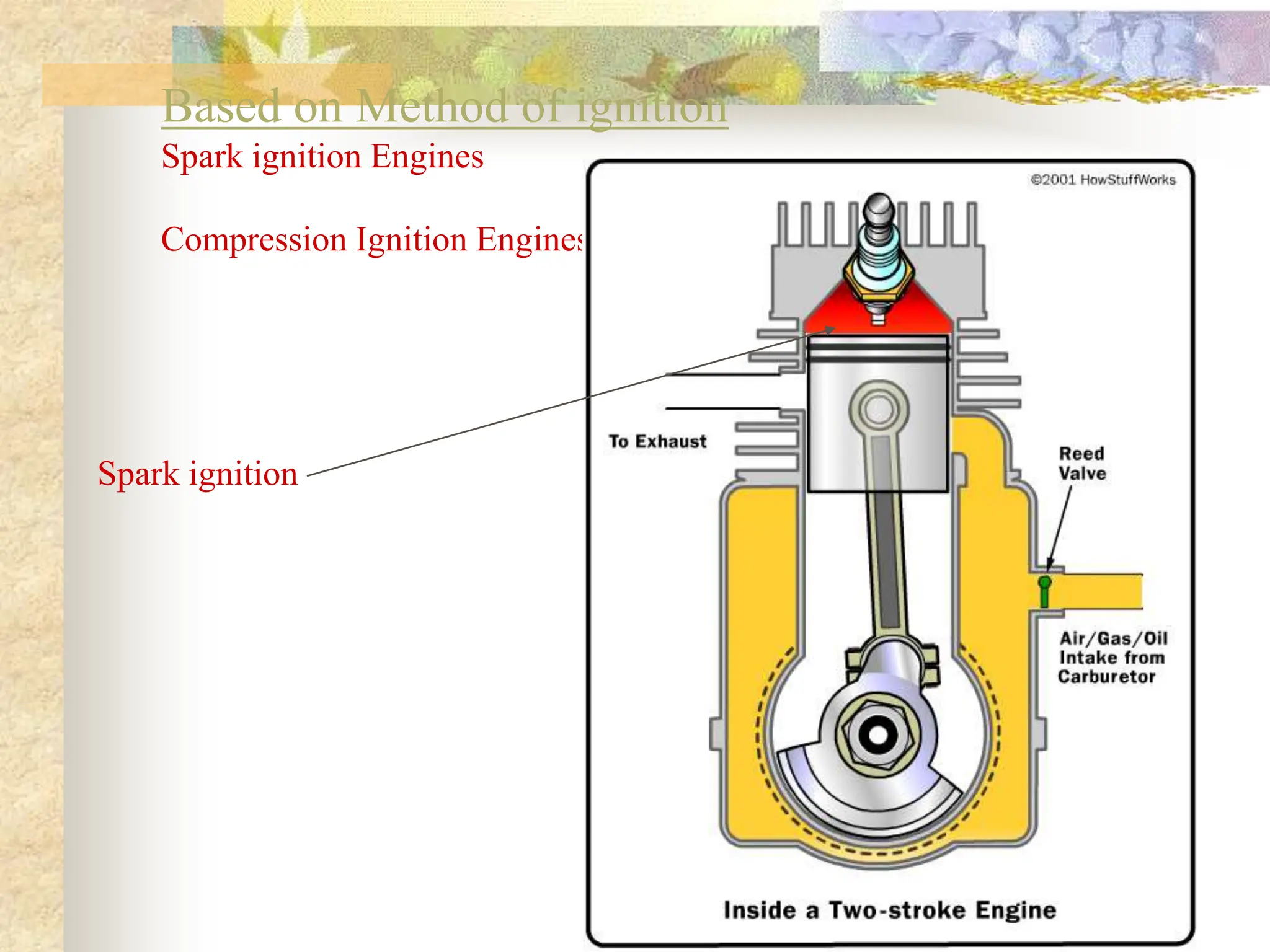

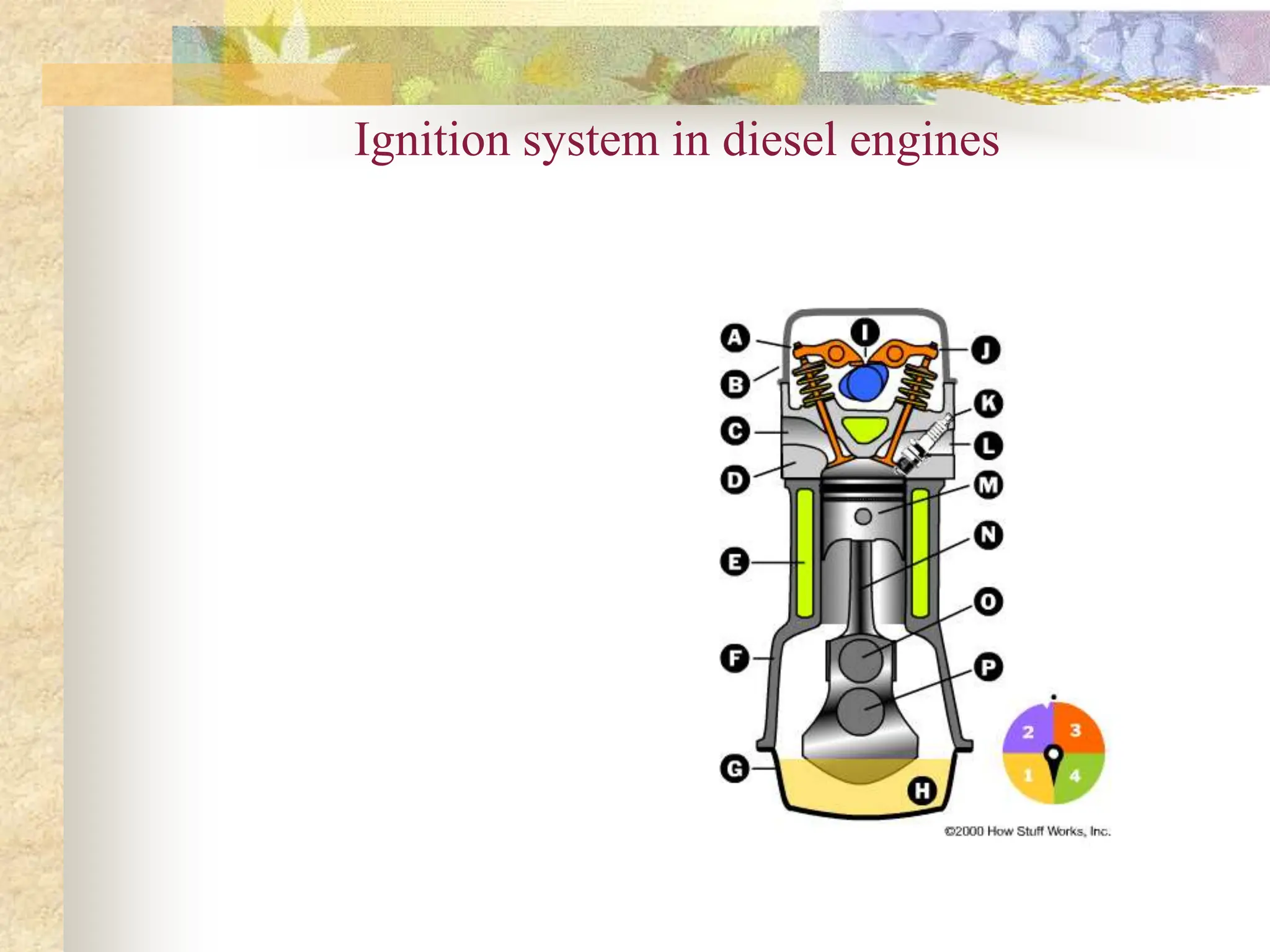

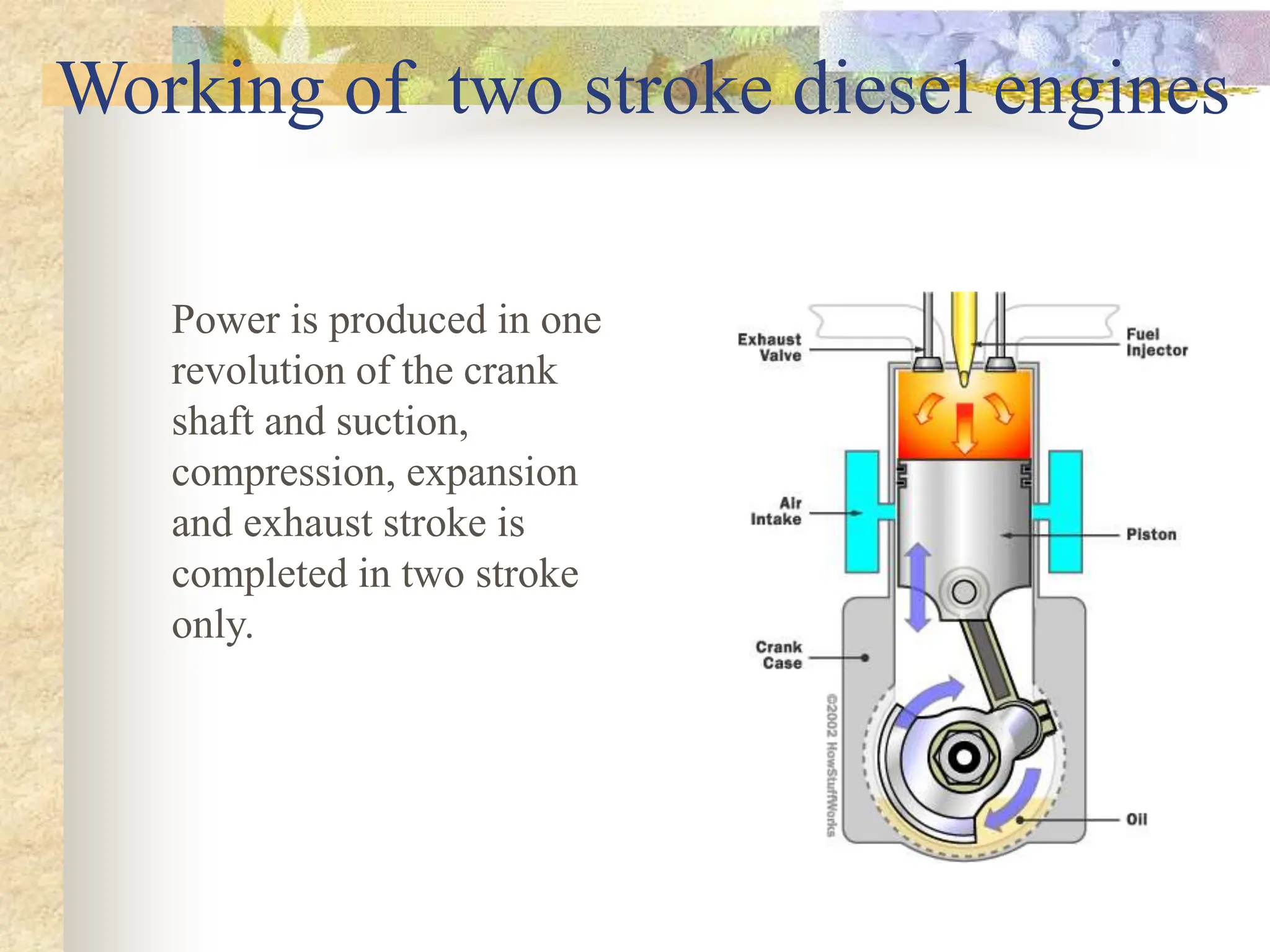

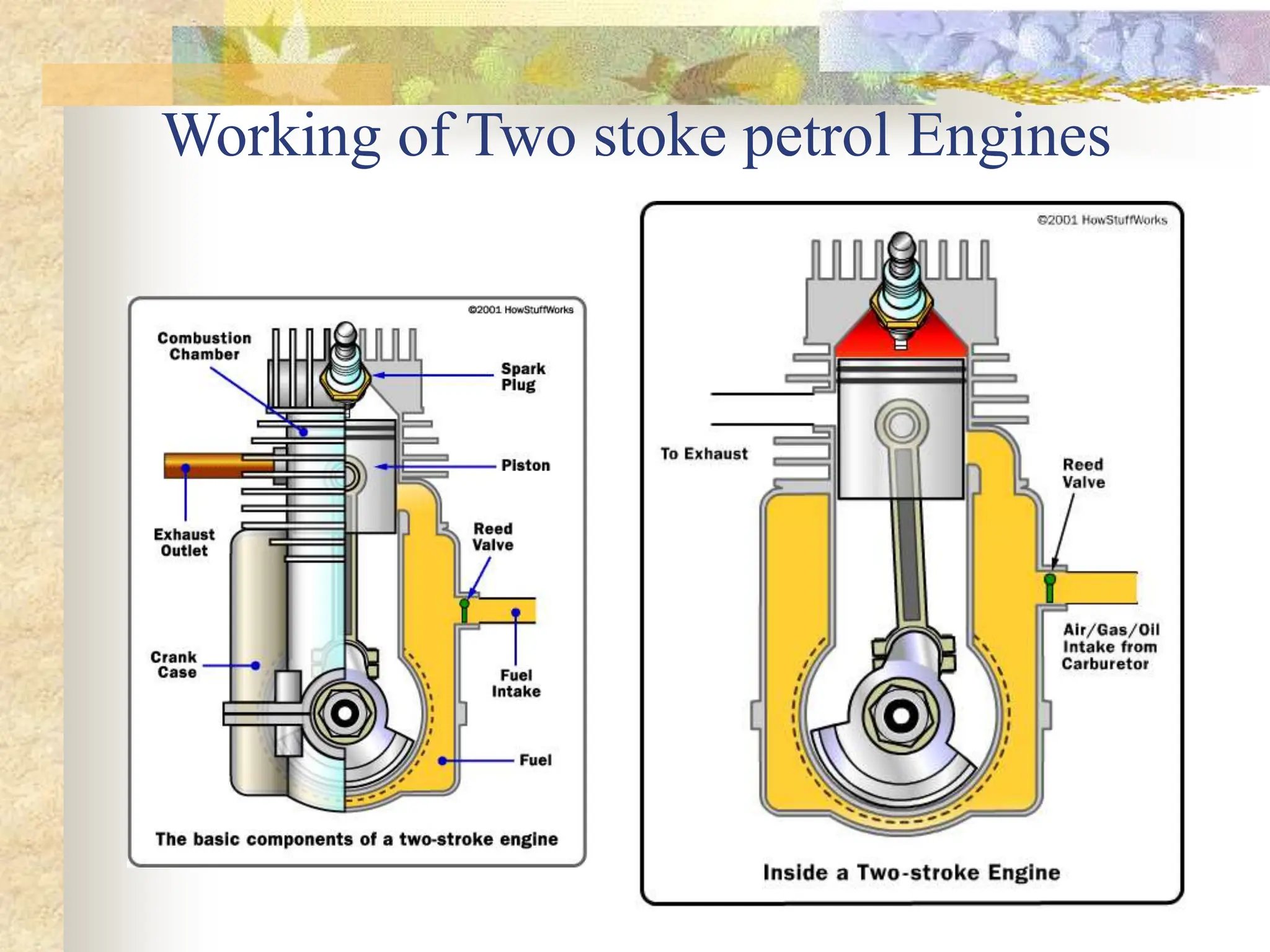

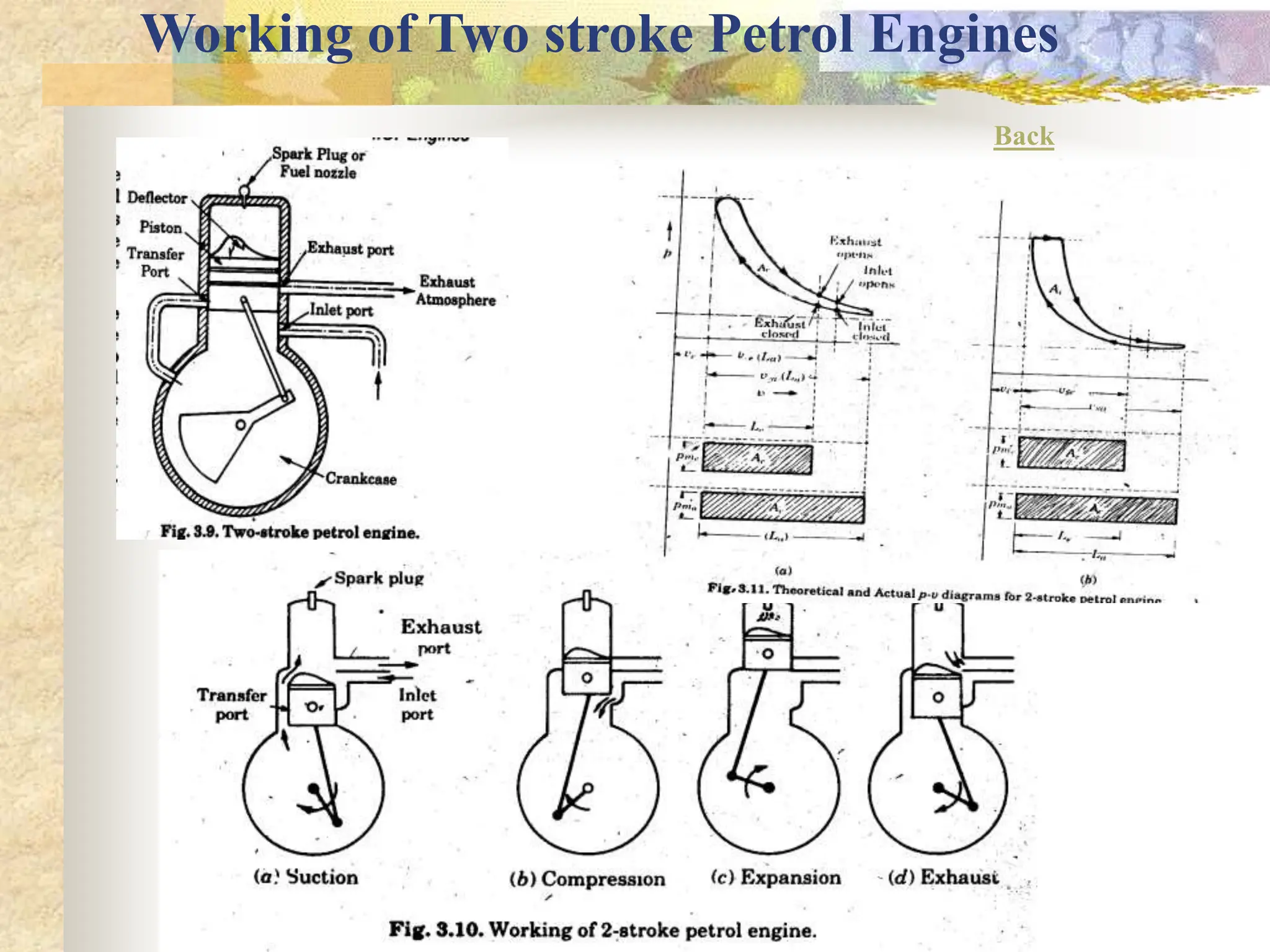

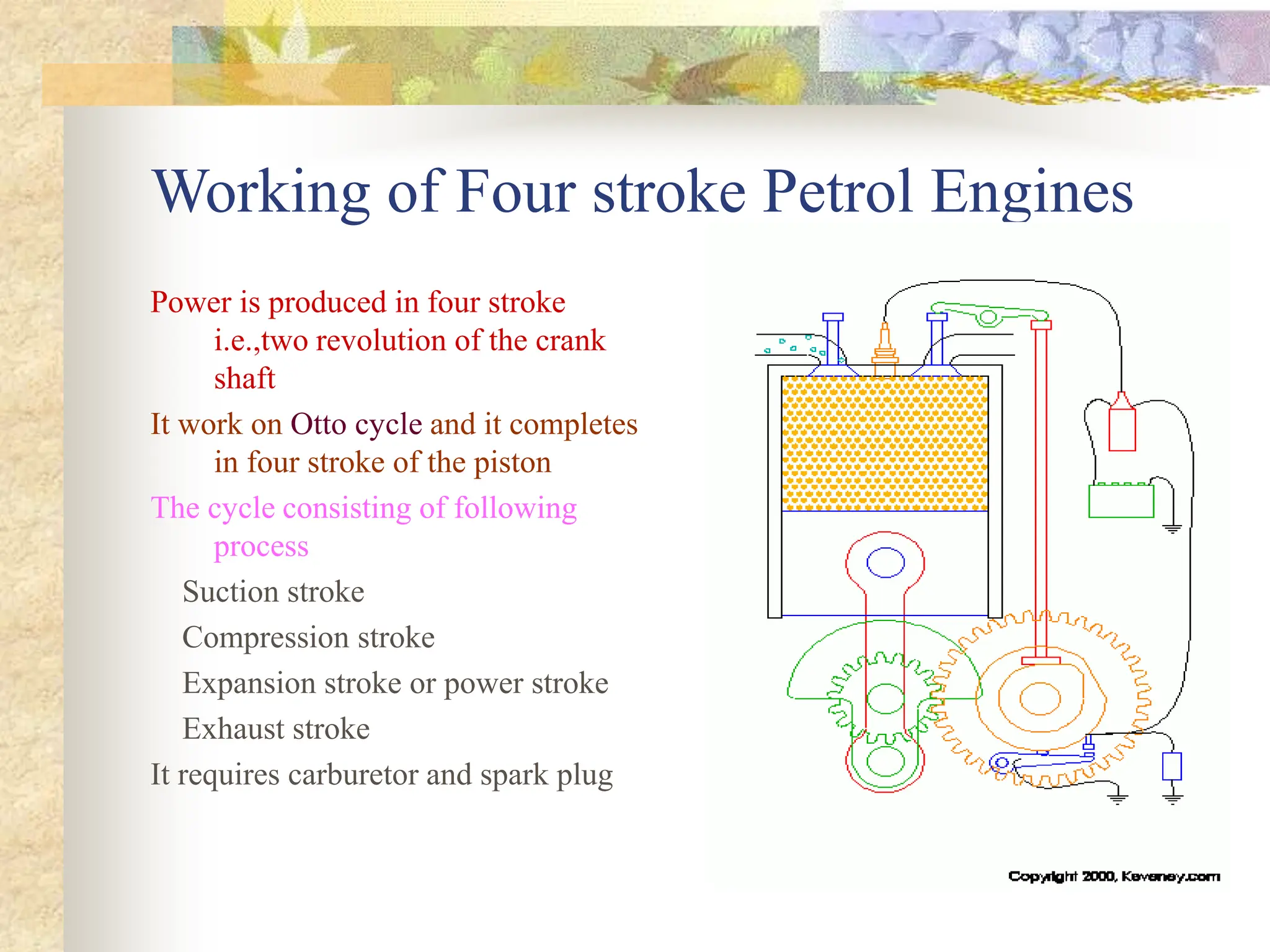

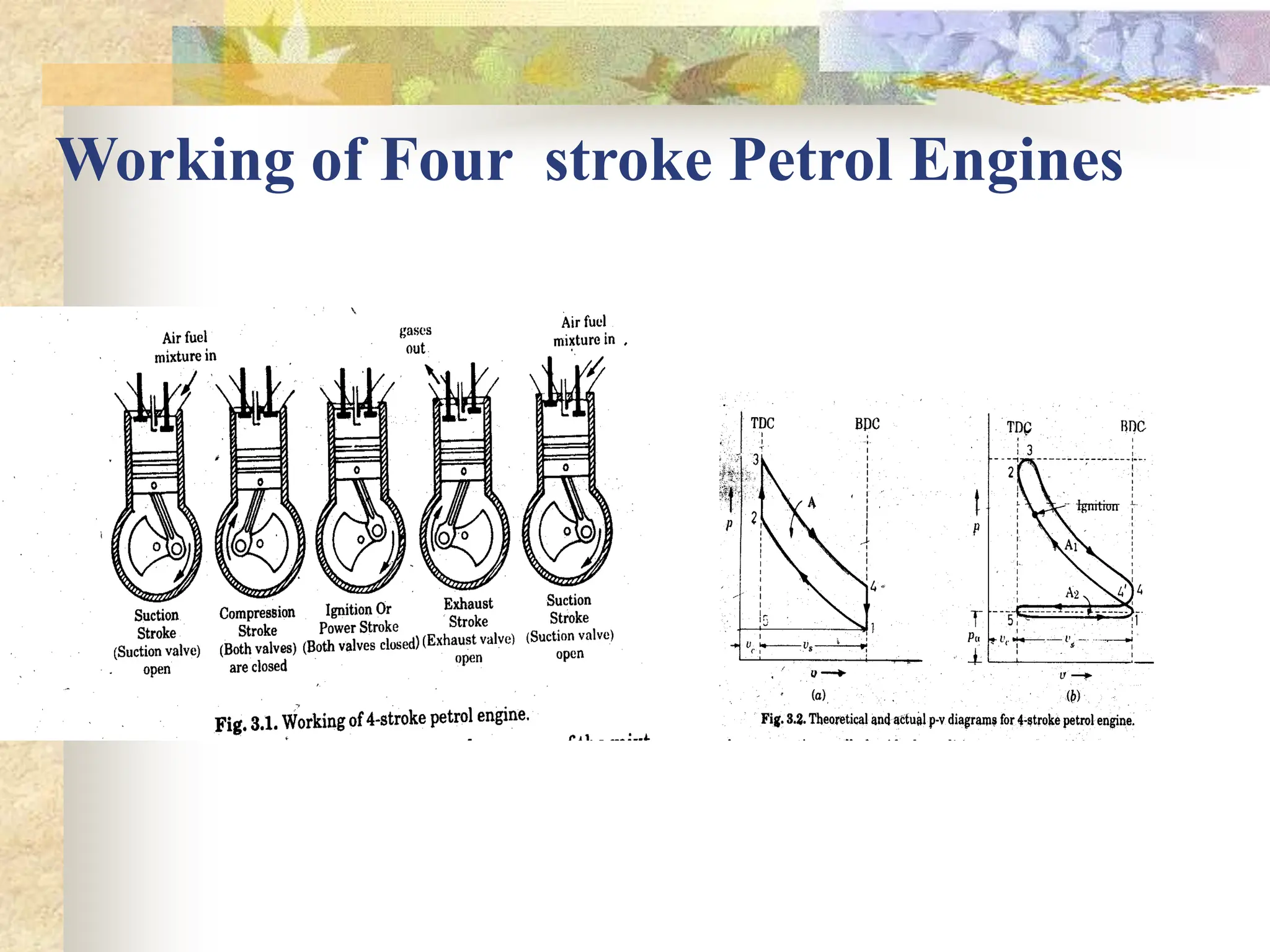

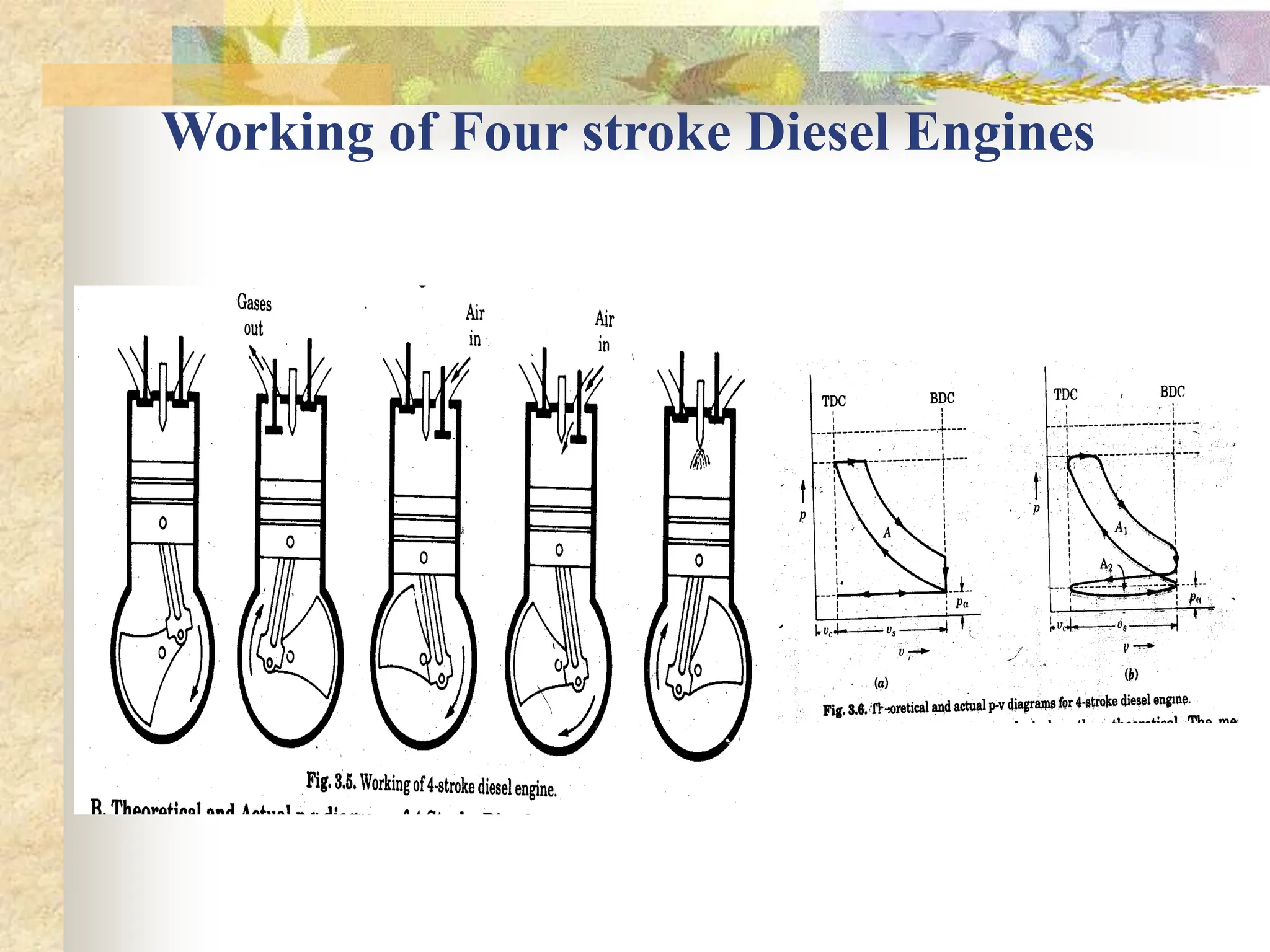

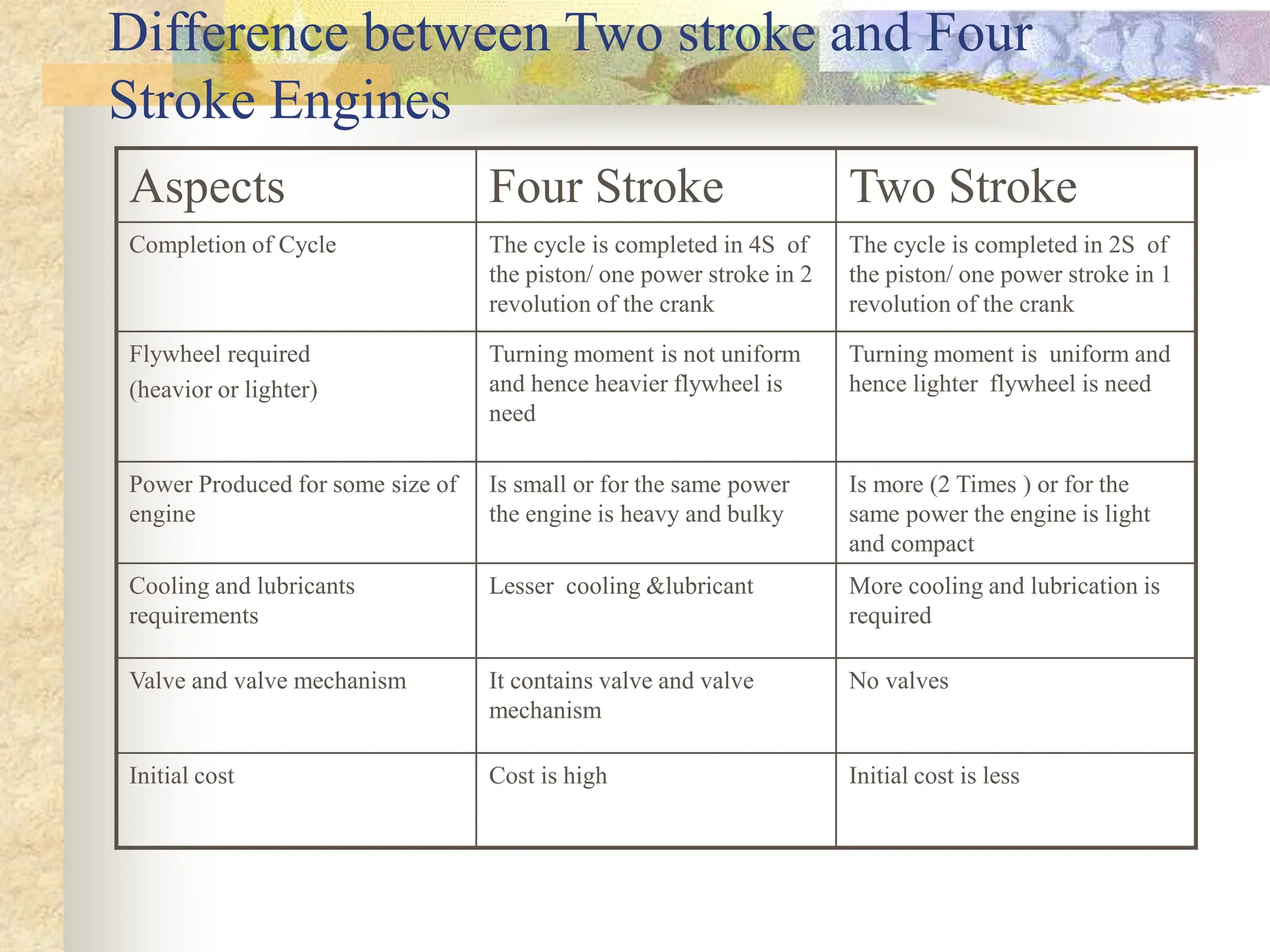

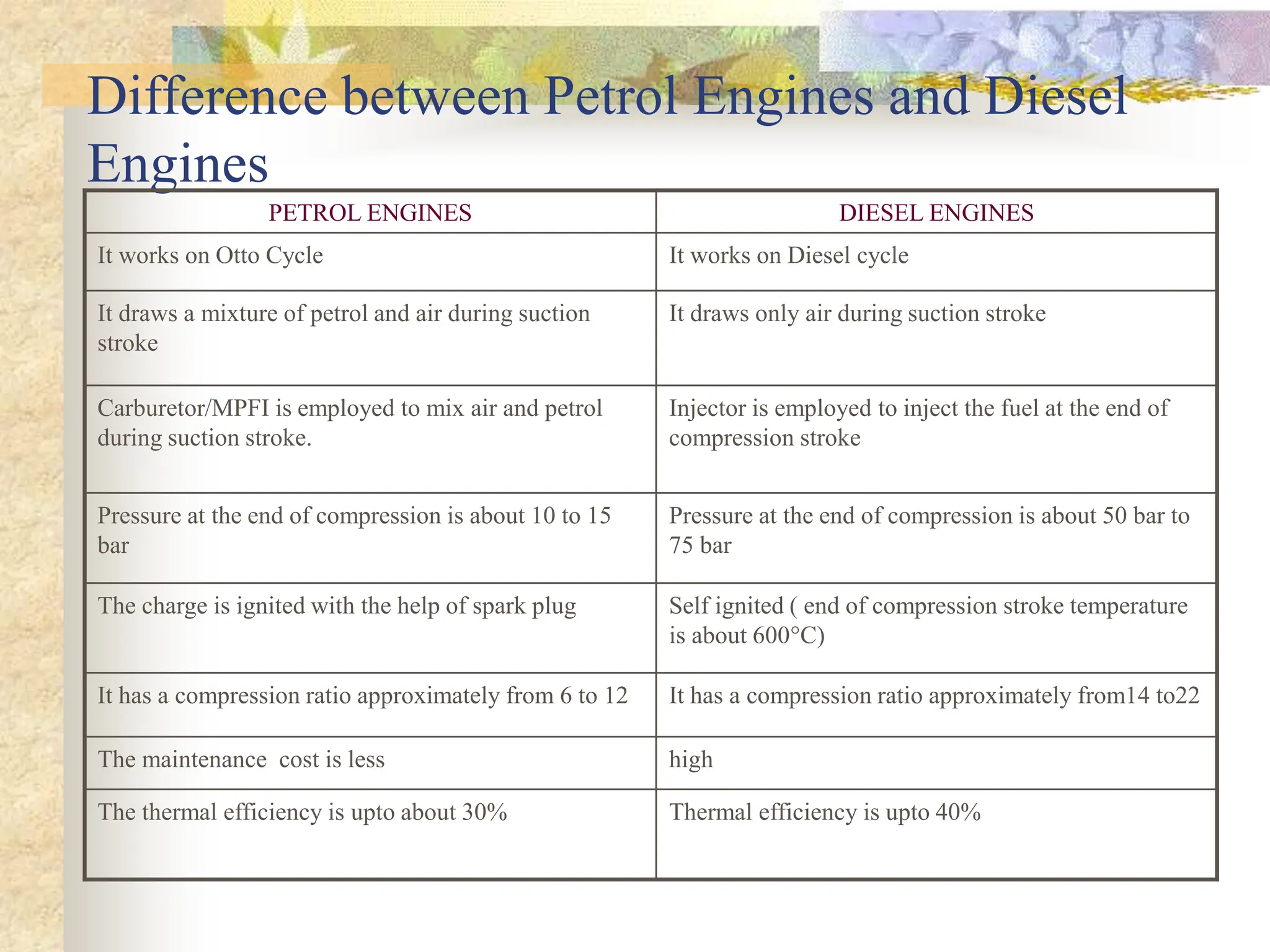

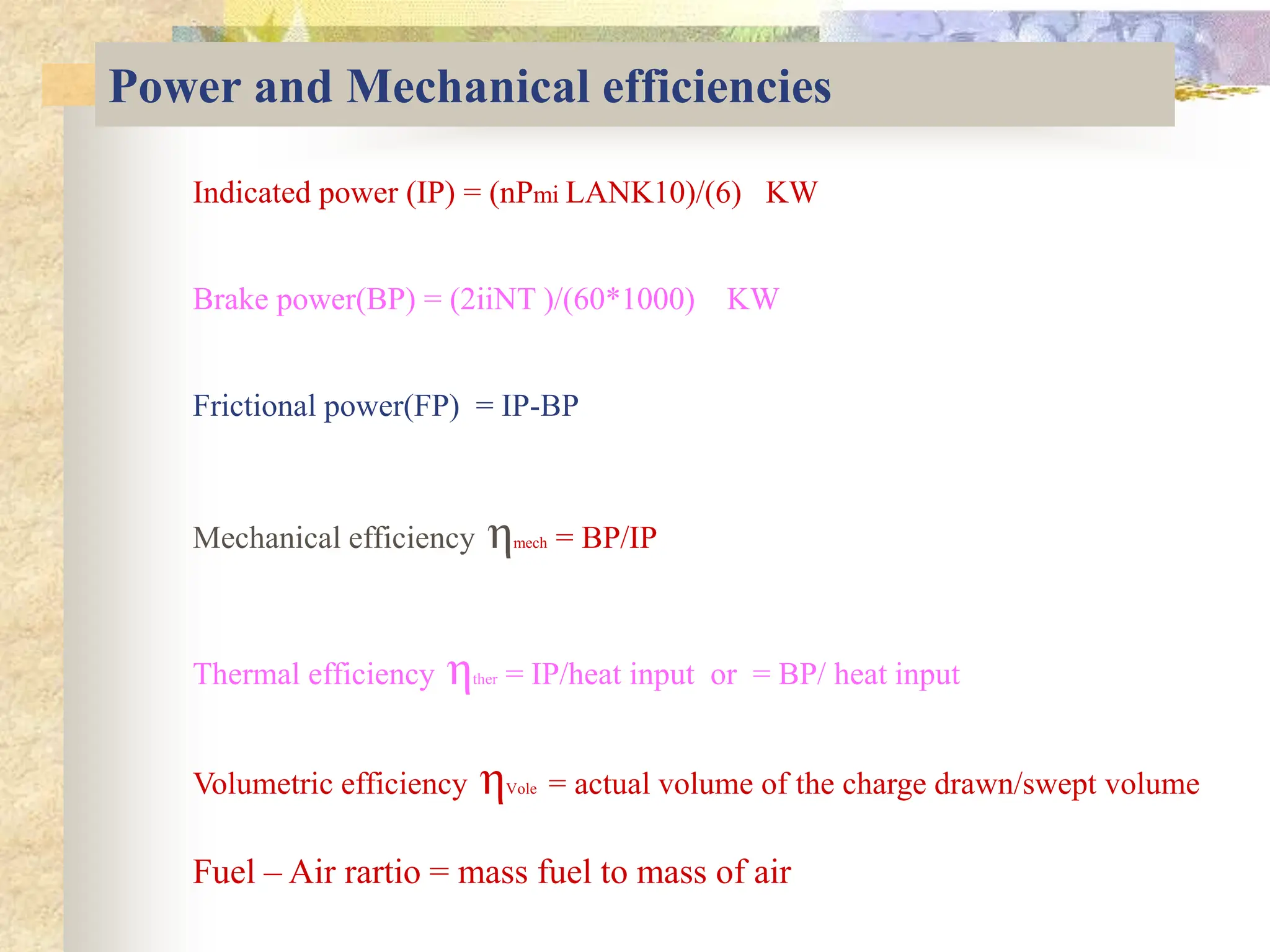

The document provides a comprehensive overview of internal combustion engines, including their introduction, applications, and classifications. It details the working principles of two-stroke and four-stroke engines, the differences between petrol and diesel engines, and the essential parts and nomenclature of these engines. Additionally, the document categorizes engines based on various criteria such as fuel type, cooling system, and ignition method.