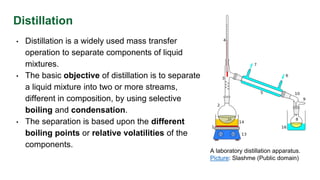

The document discusses distillation, a mass transfer operation essential for separating liquid mixtures based on boiling points or volatilities. It highlights distillation's historical applications, especially in alcohol production and petroleum refining, and details the operation of distillation columns in industrial settings. Key components of distillation, such as condensers and reboilers, are also described.

![This project has received funding from the European Union’s Horizon 2020

research and innovation programme under grant agreement No 869993.

References

Distillation fundamentals. Neutrium. Available at: https://neutrium.net/unit-operations/distillation-

fundamentals/ [Assessed: 10 June, 2021].

Dutta, B. K. 2007. Principles of mass transfer and separation processes. New Delhi: Prentice-Hall,

pp. 319-321.

Hipple, Jack. 2017. Chemical Engineering for Non-Chemical Engineers. American Institute of

Chemical Engineers, pp. 141-145.

Videos:

• Multistage distillation column demonstration: https://youtu.be/vg_buVDDEgc (2:15)

• Separating liquids by distillation: https://youtu.be/Vz2la3947I0 (5:56)](https://image.slidesharecdn.com/0-220107063908/85/0-2-Introduction-to-Distillation-8-320.jpg)