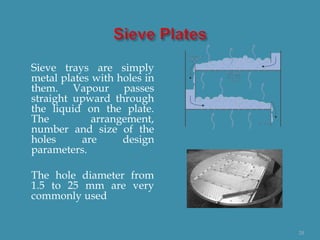

The document discusses crude oil refining processes. It begins by explaining that crude oil is initially separated into fractions through distillation, but the distilled fractions require further processing to meet market needs. Additional complexity arises from environmental regulations requiring cleaner products. The document then provides details on various refining processes like distillation, solvent extraction, and cracking used to convert crude oil fractions into useful products like gasoline and diesel.