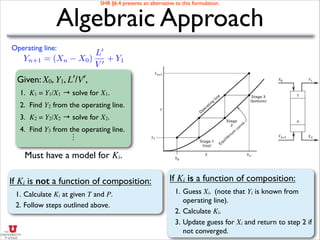

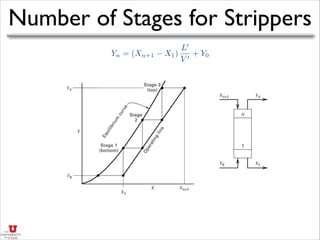

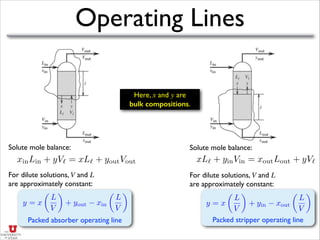

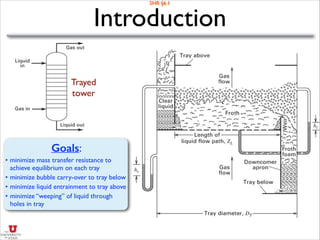

- This document describes absorption and stripping processes using packed columns and graphical methods.

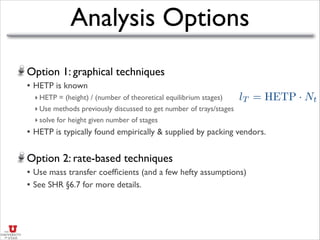

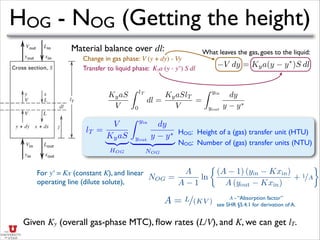

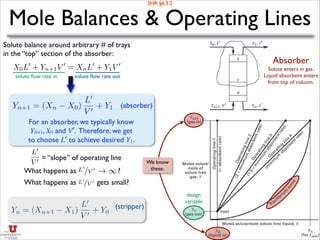

- It discusses operating lines, height of transfer units (HOG), number of transfer units (NOG), and how to calculate the height equivalent of a theoretical plate (HETP) for a packed column given mass transfer coefficients, flow rates, and equilibrium data.

- An example is provided to calculate the HETP for a specific packed column based on the mass transfer coefficients, flow rates, and equilibrium constant given.

![Absorber: Minimum Flow Rate

Yn+1 = (Xn X0)

L0

V 0

+ Y1

Absorber

Solute enters in gas.

Liquid absorbent enters

from top of column.

L0

=

V 0

(YN+1 Y1)

XN X0

Over the whole tower (n=N):

L′min corresponds to equilibrium

with XN and YN+1.

KN =

yN+1

xN

=

YN+1/(1+YN+1)

XN/(1+XN )

For dilute solutes (Y ≈ y and X ≈ x):

If X0 ≈ 0 then:

L0

min = V 0

✓

yN+1 y1

yN+1/KN x0

◆

Corresponding

equation for a

stripper:

L0

min =

V 0

(YN+1 Y1)

YN+1/[YN+1(KN 1)+KN ] X0

As V′ ↑, L′min↑.

SHR §6.3.3

Why are these in equilibrium?

L0

min = V 0

KN · (fraction absorbed)

V 0

min =

L0

KN

· (fraction stripped)

This is the “best” we can achieve

given the inlet constraints.](https://image.slidesharecdn.com/absorptionstripping-161122015839/85/Absorption-stripping-12-320.jpg)