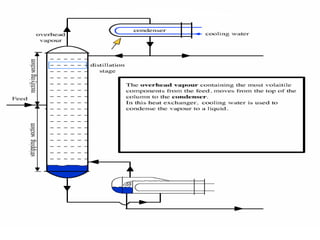

The document describes distillation as a separation process that utilizes heat to divide a liquid or vapor mixture into its components based on boiling points. It outlines two types of distillation columns: batch and continuous, detailing their operations and components including reboilers and condensers. Additionally, it explains heat exchangers, specifically shell and tube heat exchangers, and their applications in various cooling and heating processes.