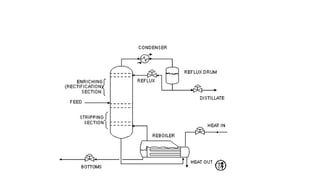

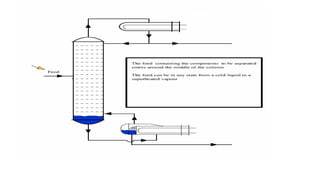

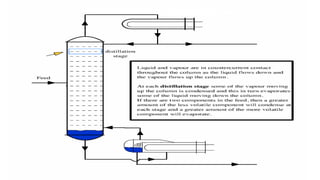

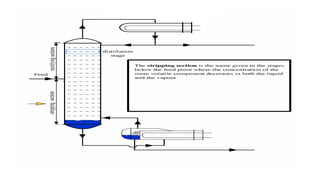

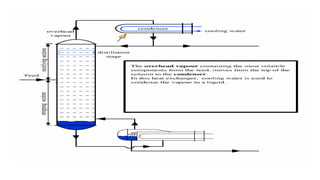

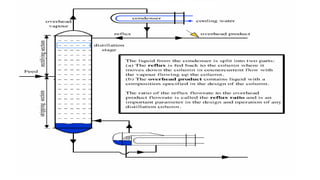

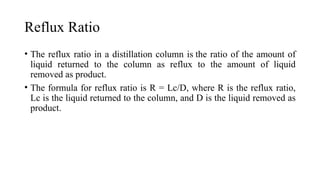

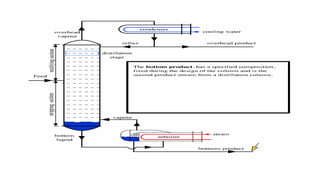

Distillation columns separate liquid mixtures based on boiling points, utilizing either batch or continuous processes. Essential components include a vertical shell, column internals (like trays/plates), a reboiler, a condenser, and a reflux drum. The operation involves generating vapour in the reboiler, with the reflux ratio determining the amount of liquid recycled versus removed as product.