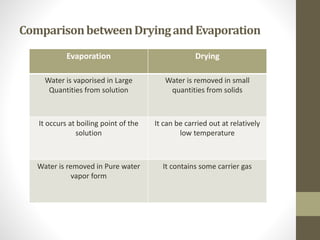

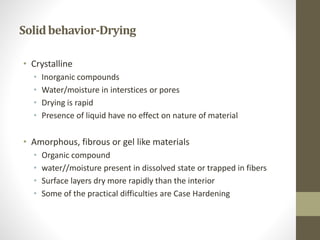

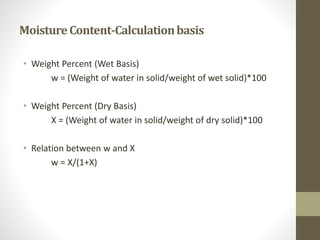

Drying is a process that removes moisture from solids through heat transfer and evaporation. It is used across many industries to preserve and process materials like food, paper, chemicals and more. There are different types of dryers classified by their heat transfer method (direct, indirect, radiative), operation method (batch, continuous), and material flow. Proper drying ensures materials are preserved, easier to transport and package, and maintains desired properties.