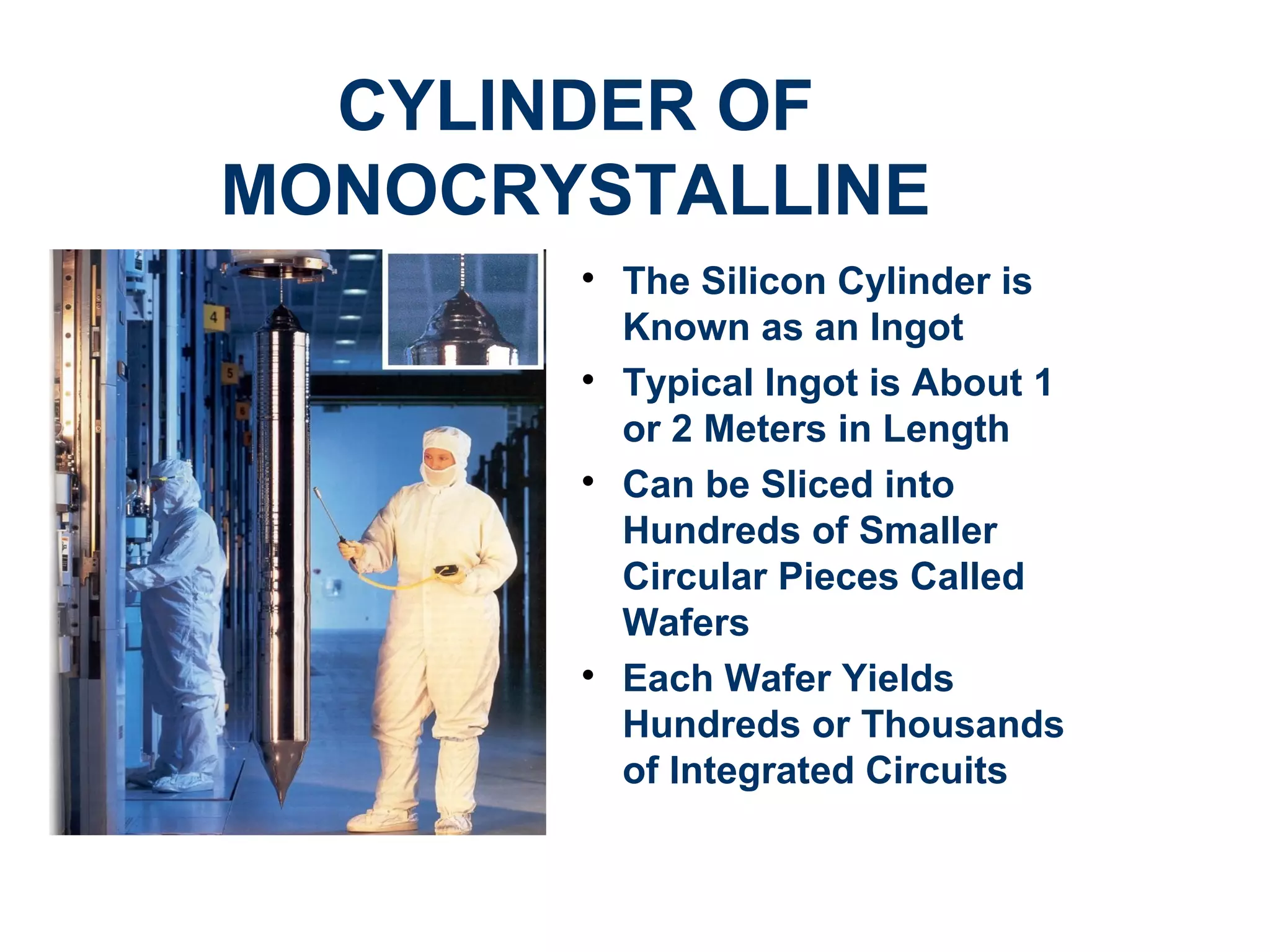

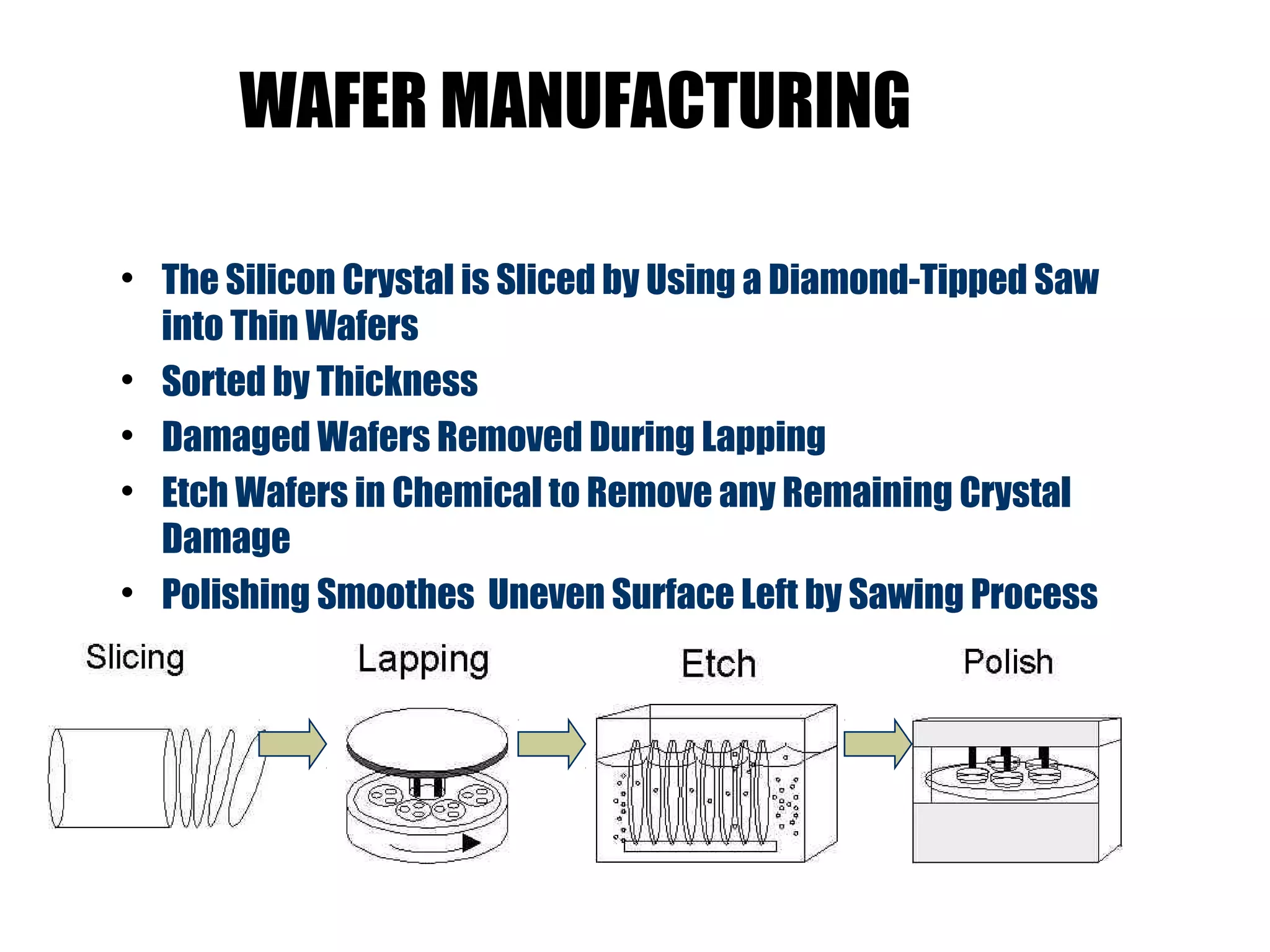

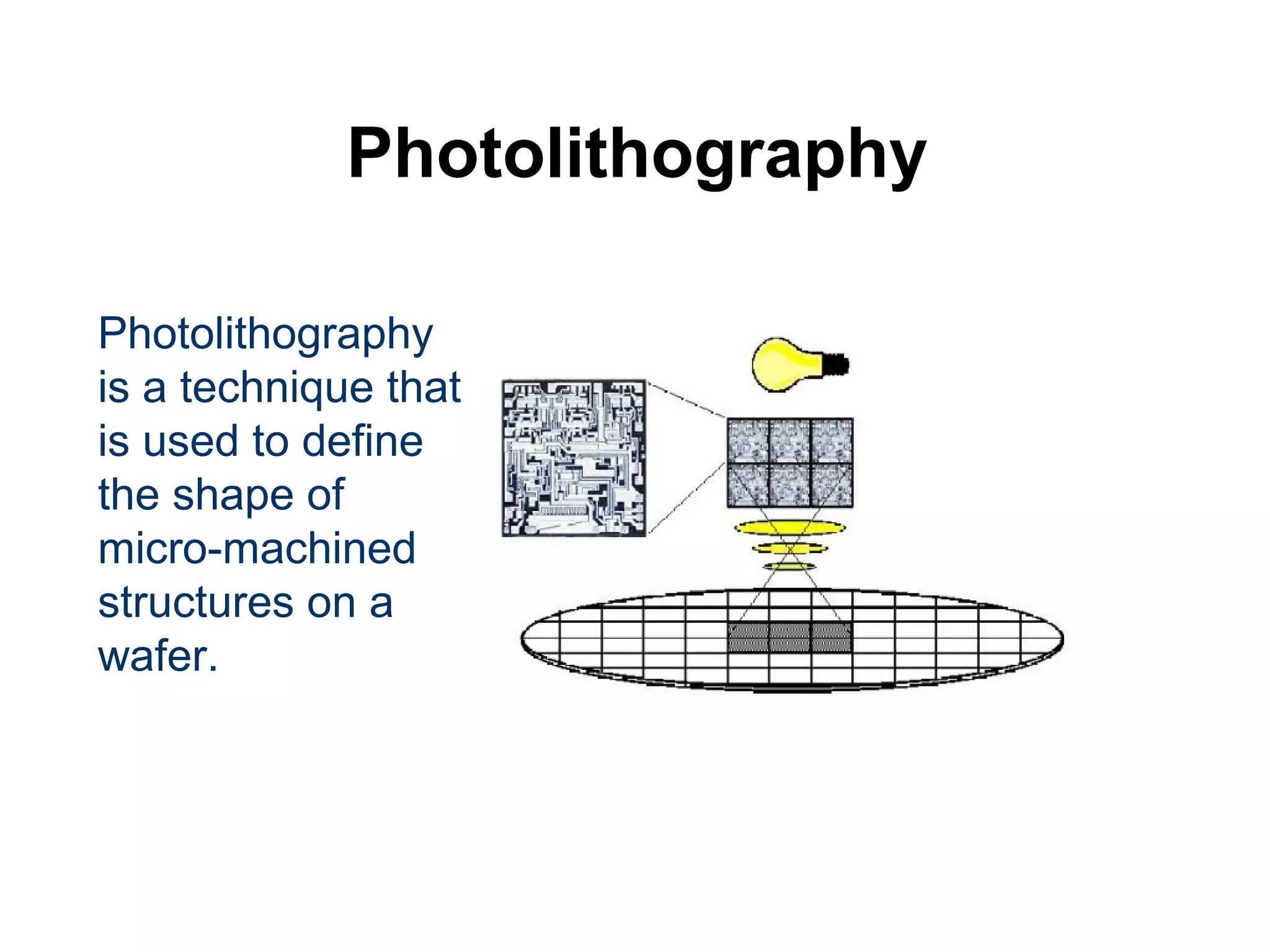

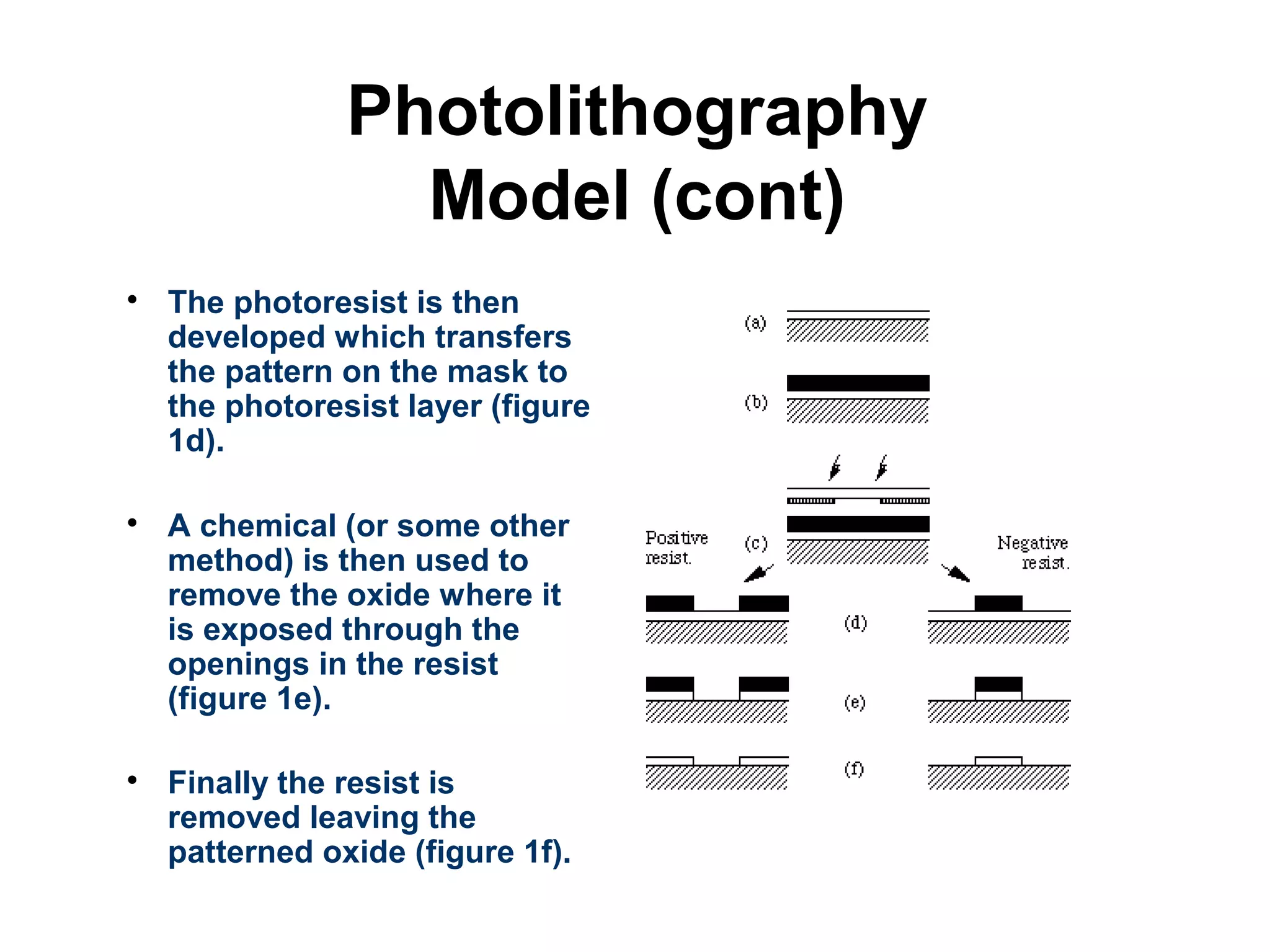

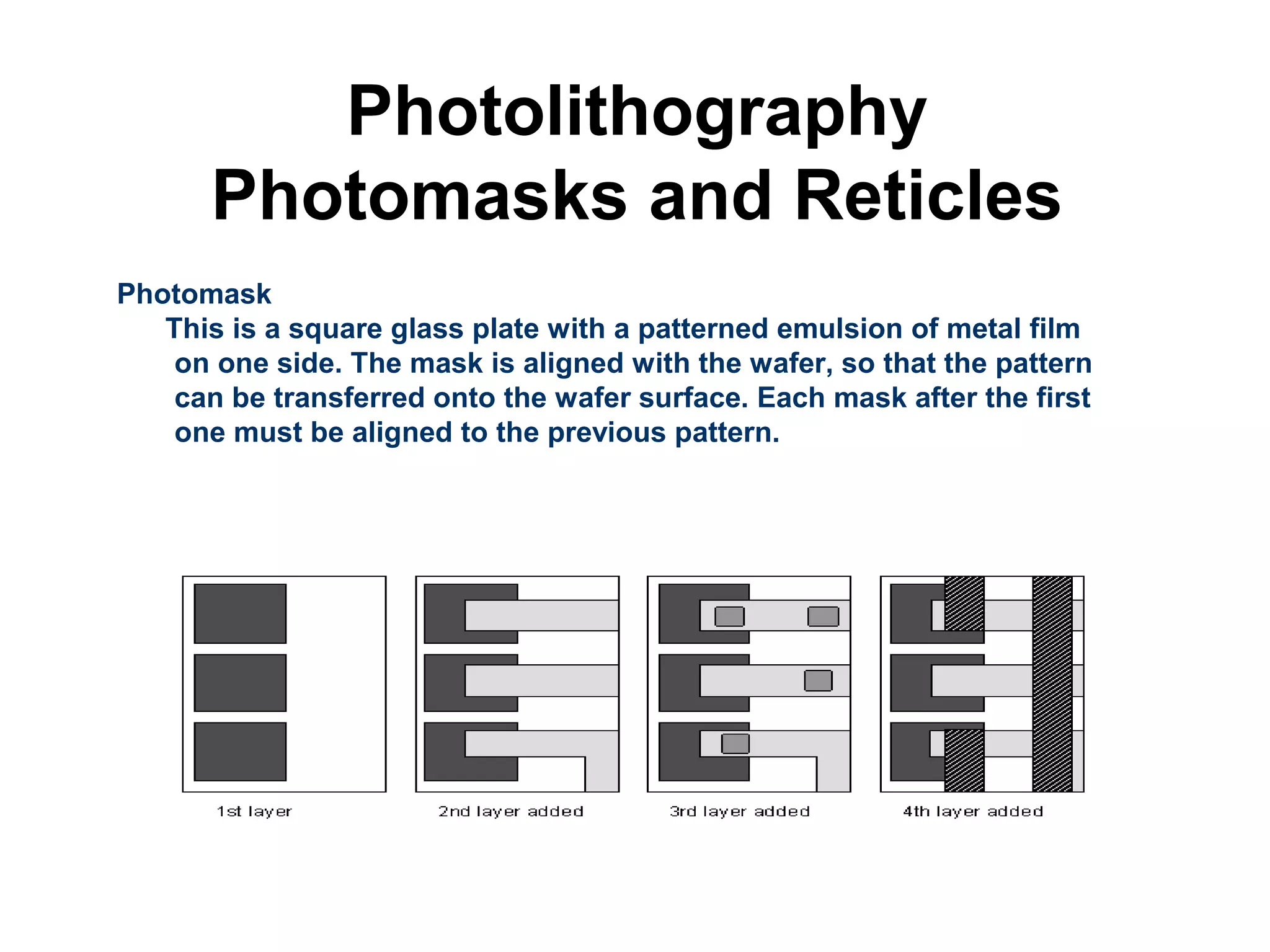

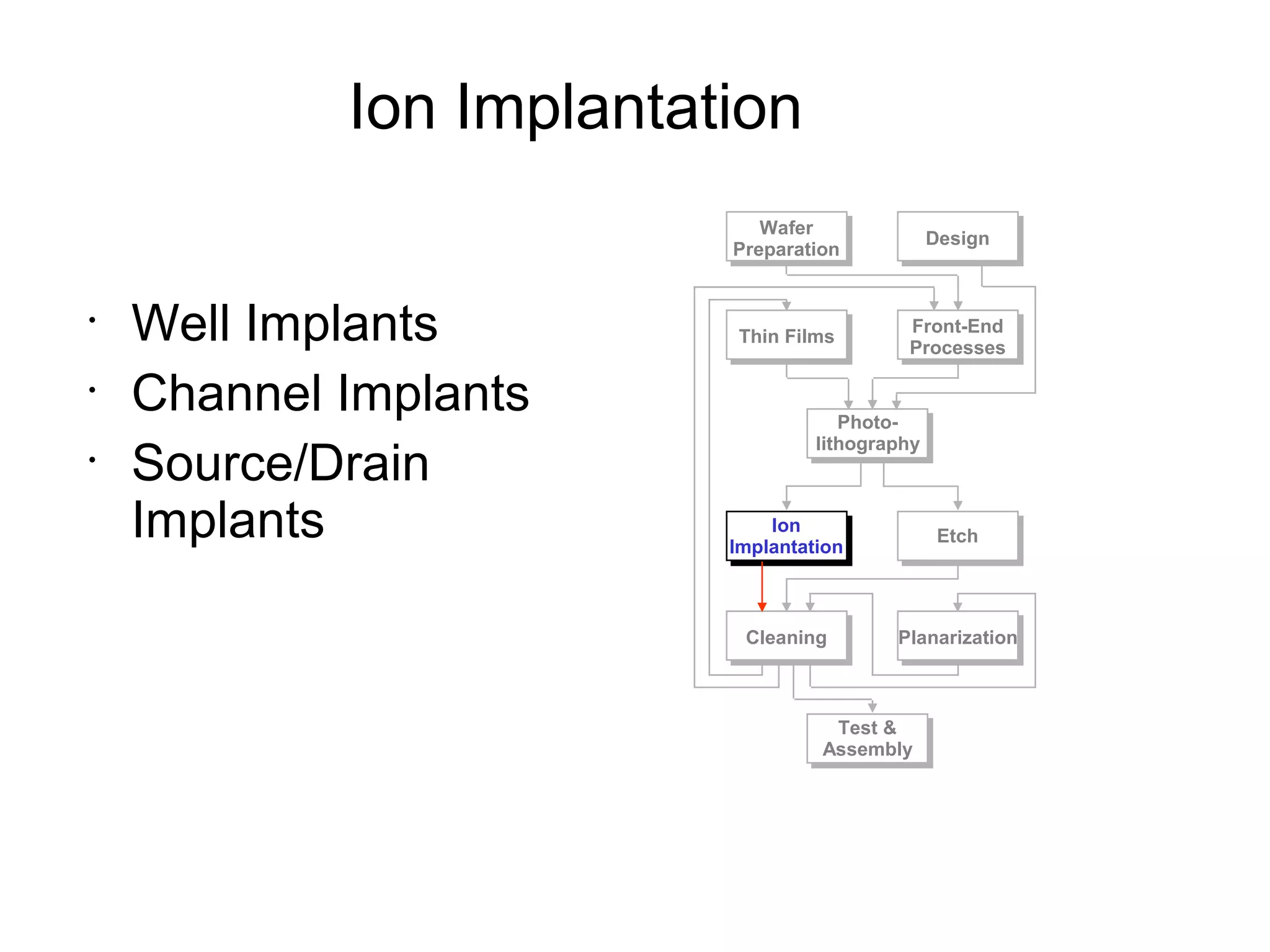

The document describes the key steps in the semiconductor manufacturing process including silicon manufacturing using the Czochralski method, photolithography using photoresists and photomasks, and ion implantation. Photolithography involves coating wafers with photoresist, exposing it to light through a photomask, and developing the resist to transfer patterns. Ion implantation injects dopants by accelerating ions toward the wafer surface.