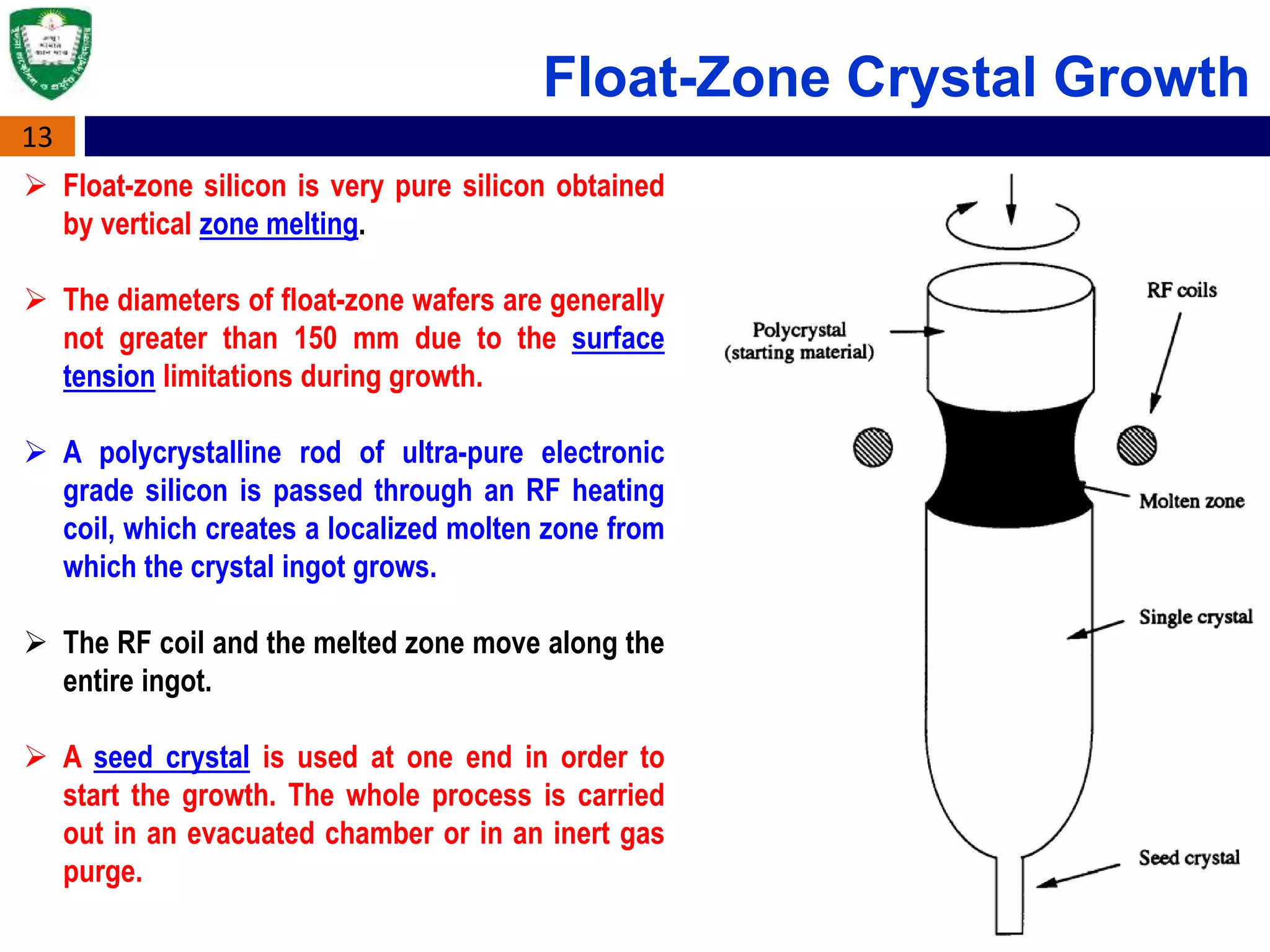

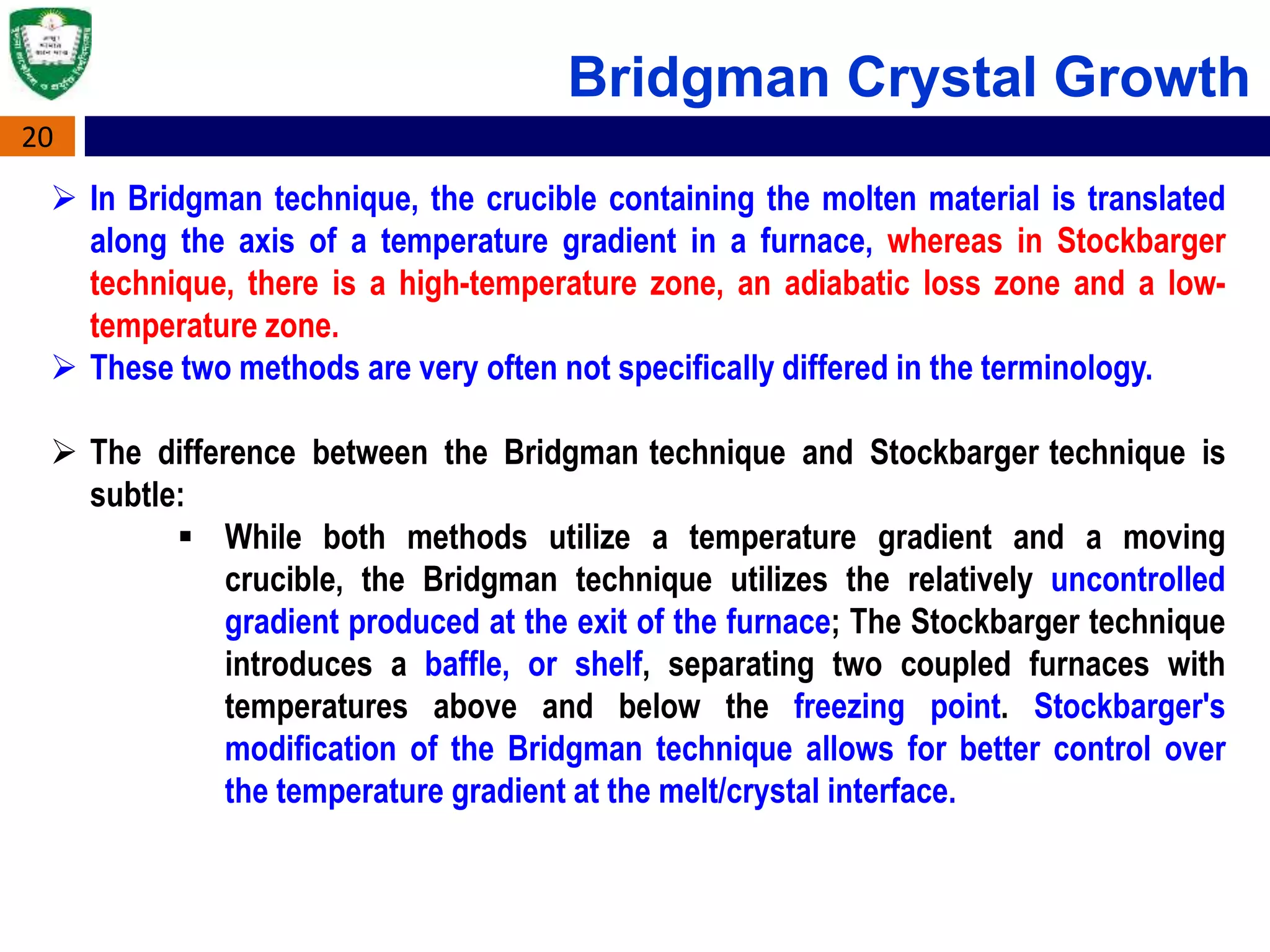

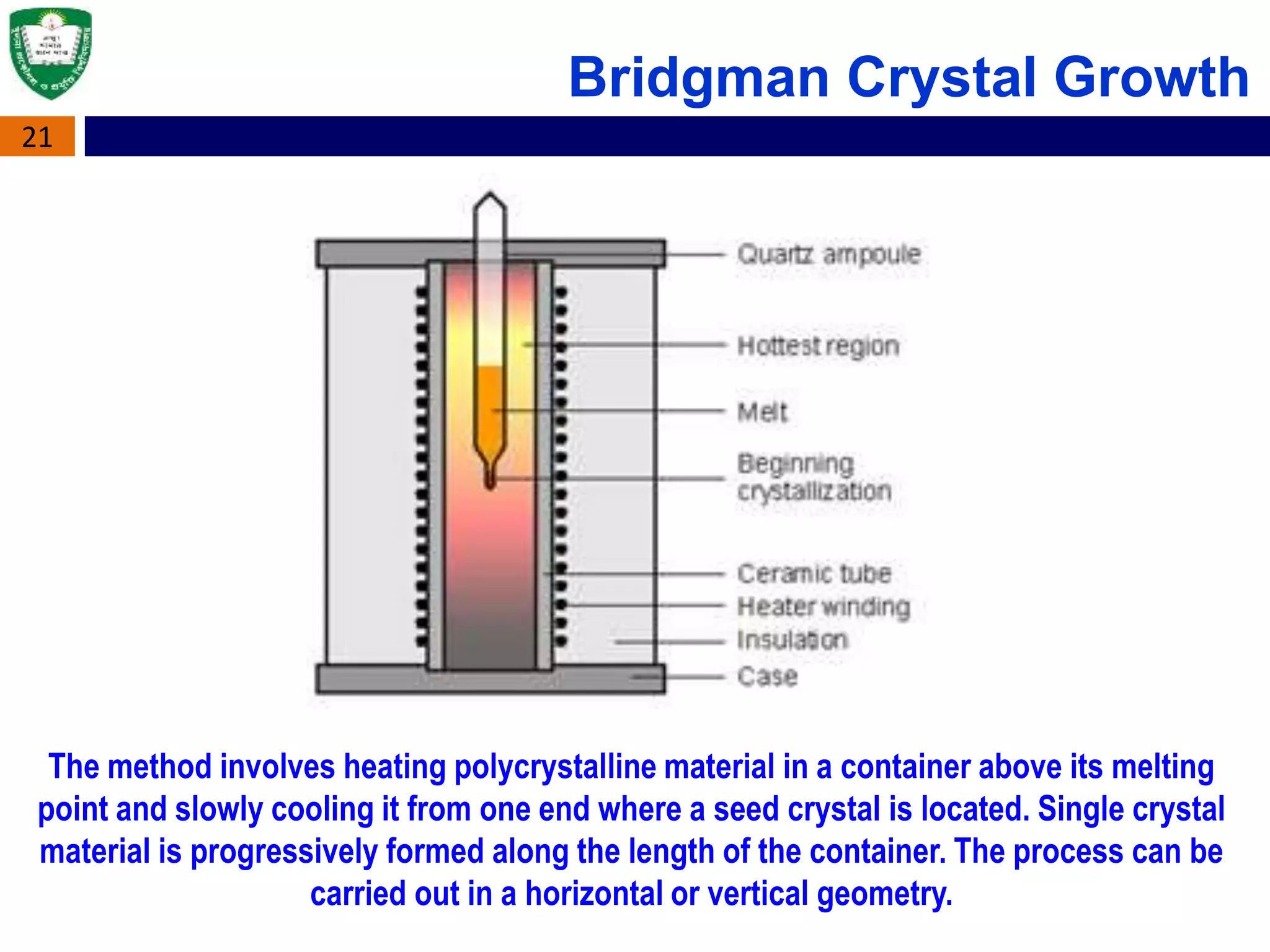

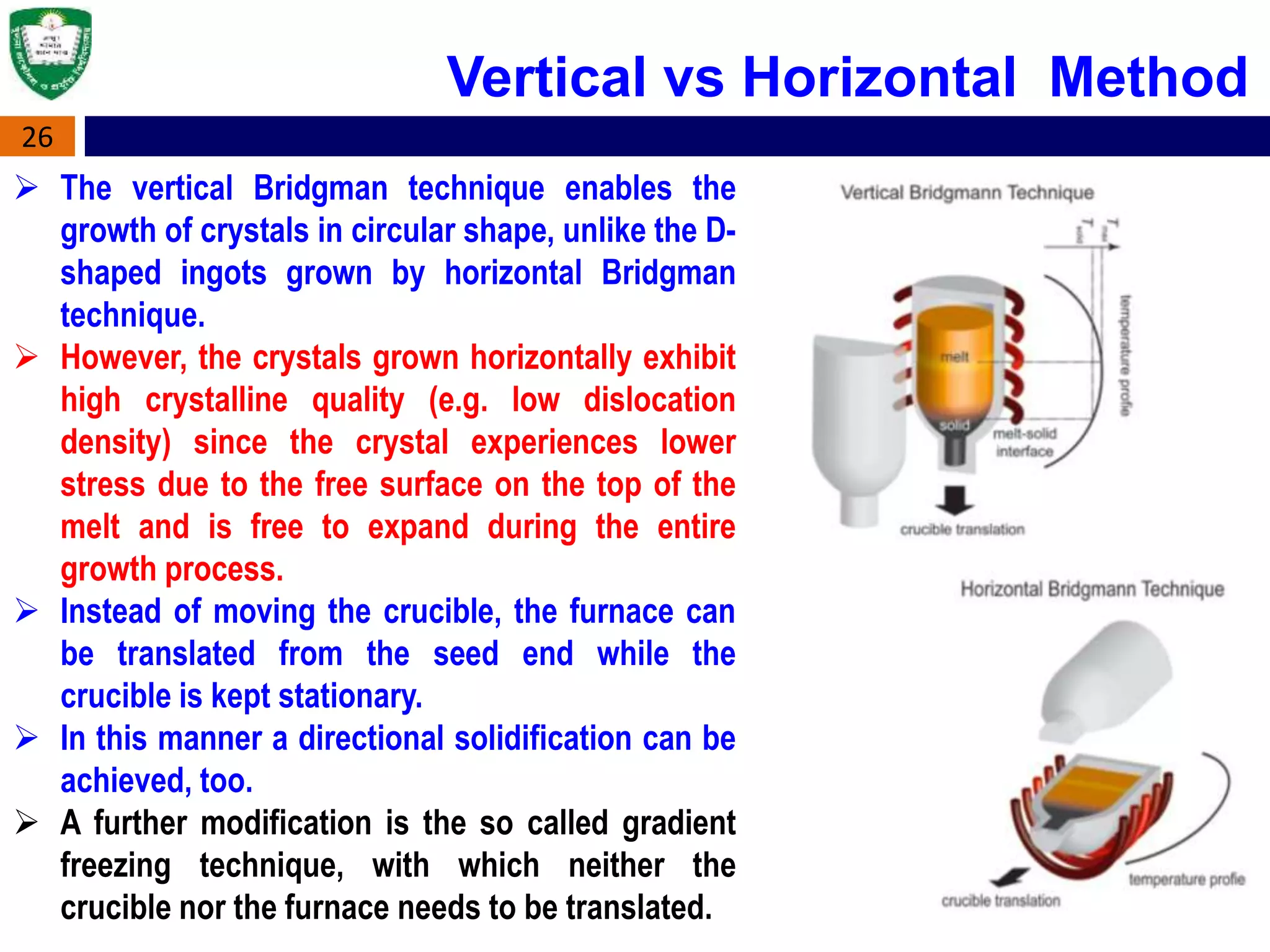

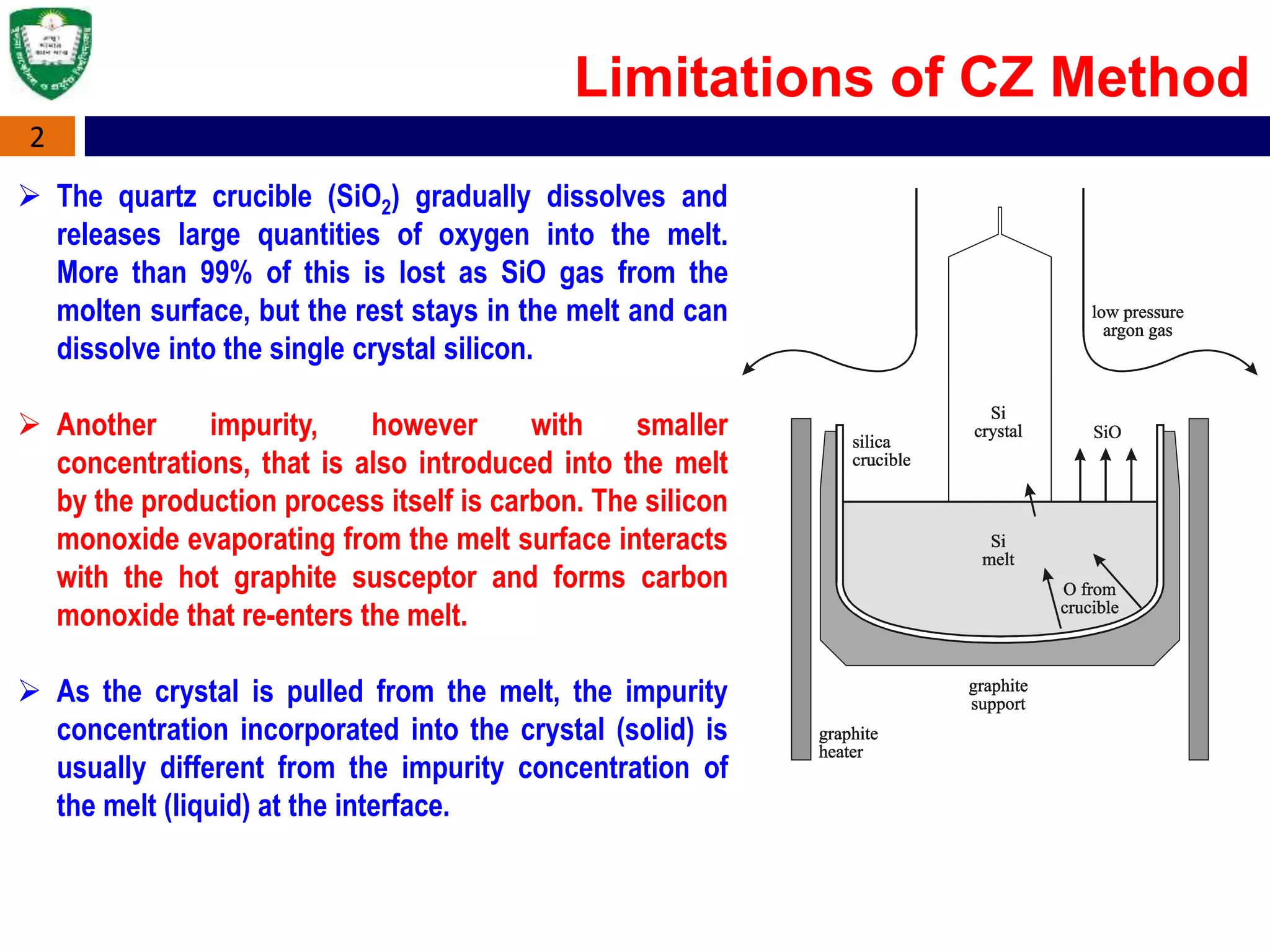

The document discusses various crystal growth techniques including Czochralski (CZ), float zone, and Bridgman techniques. It describes the limitations of the CZ method including impurities introduced from the quartz crucible. The float zone technique produces very pure silicon crystals but allows for smaller wafer sizes. The Bridgman technique employs a temperature gradient to slowly cool a melt contained in a crucible to produce a single crystal ingot.

![3

Typical oxygen and carbon concentrations are [O] ≈ 5-10 10^17cm-3 and [C] ≈ 5 - 10

10^15cm-3, respectively, which lower the minority carrier diffusion length in the

finished silicon wafer.

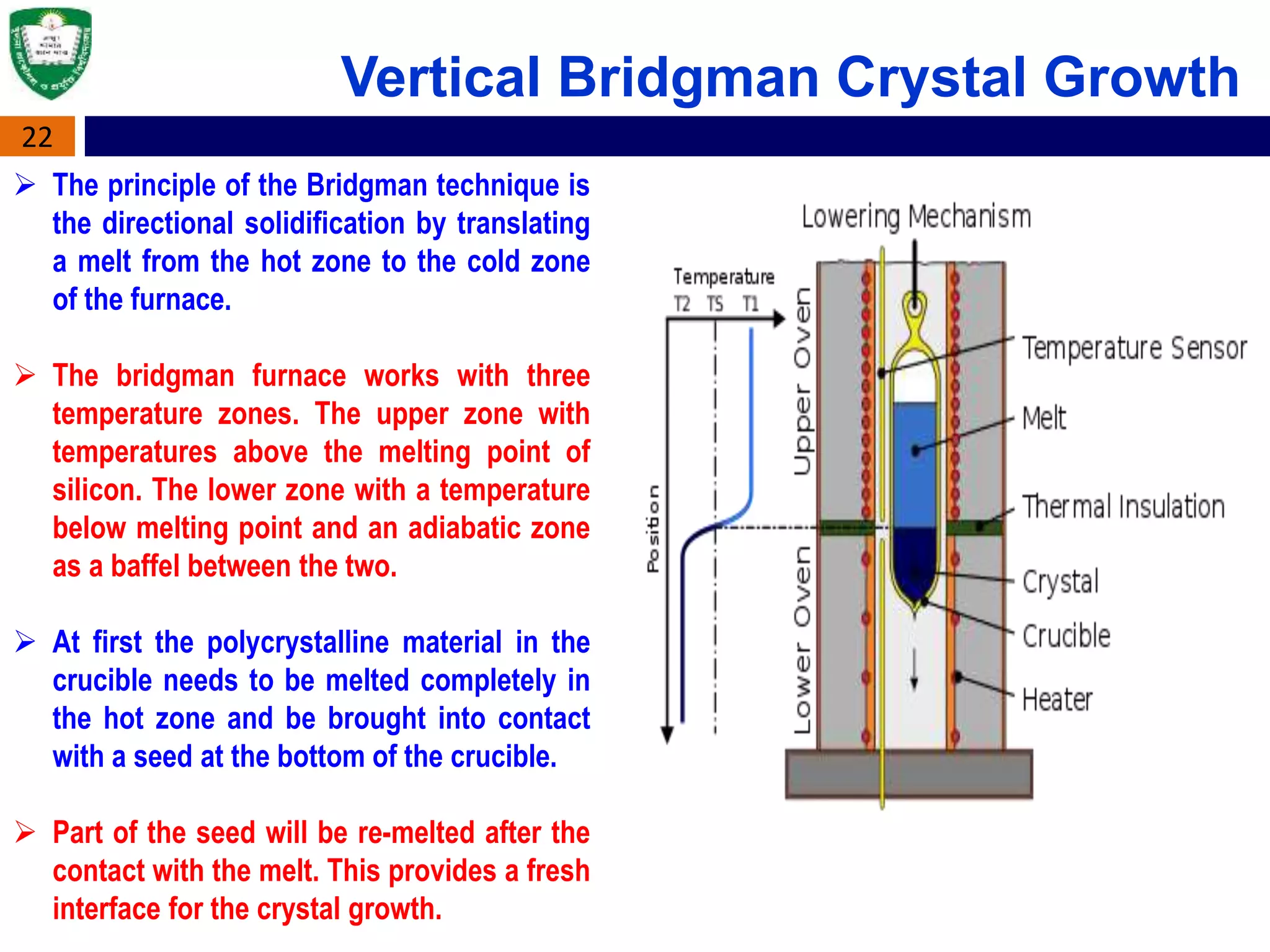

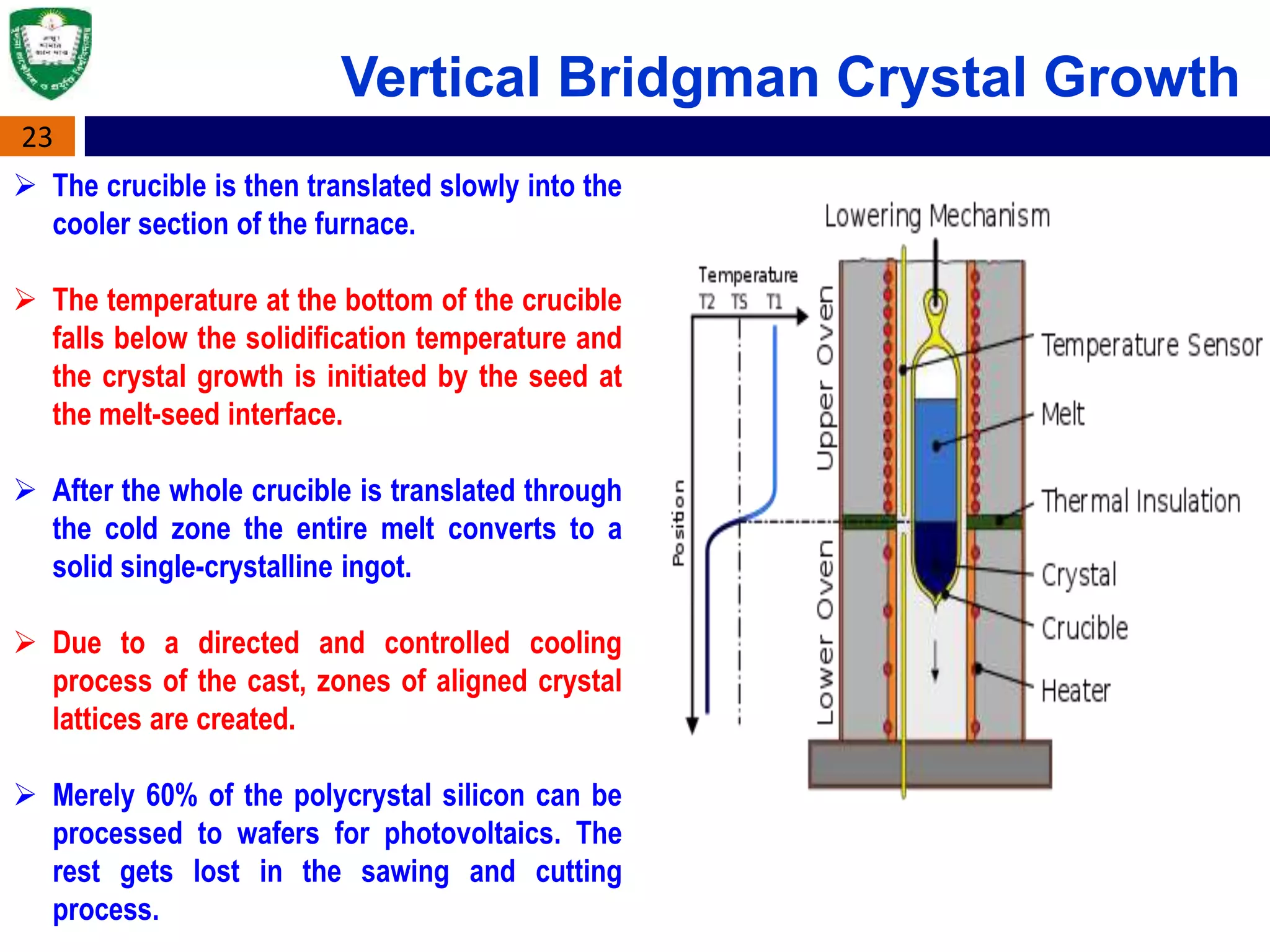

Low homogeneity of the axial and radial dopant concentration in the crystal caused

by oscillations in the melt during crystal growth. This makes it difficult to attain

high-ohmic CZ-wafers with a resistivity exceeding 100 Ohm cm.

Furthermore the high oxygen concentration can lead to the formation of unwanted

electrically active defects. These are oxygen related thermal double donors (TDD)

and shallow thermal donors (STD) which can seriously change the resistivity of the

material.

Limitations of CZ Method](https://image.slidesharecdn.com/1551655721ee4121lecture-3-190527091455/75/Float-Zone-Bridgman-Techniques-ABU-SYED-KUET-3-2048.jpg)