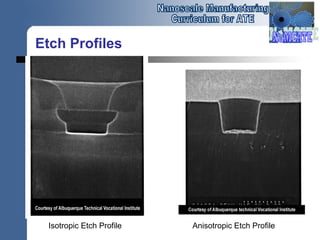

This document discusses various etching techniques used in microfabrication processes. It describes isotropic and anisotropic etching, and how etch rate and profile depend on the orientation of the crystalline planes. Wet etching involves immersing wafers in chemical solutions and proceeds equally in all directions, limiting it to features larger than 3um. Dry etching uses gases or plasma and can achieve better anisotropy. The document outlines properties of etch processes like rate, uniformity, profile and selectivity. It provides examples of wet etch chemistries and discusses advantages and disadvantages of wet versus dry etching.

![Sources and References

[1] Xaio, Hong (2001). Introduction to Semiconductor Manufacturing Technology Prentice-Hall,

Upper Saddle River, NJ

[2] Van Zant, P. (1997). Microchip Fabrication, (3rd

ed.). McGraw-Hill.

[3] The Texas Engineering Extension Service, (1996). Semiconductor Processing Overview, Texas A&M

University System, p. 139-153..

[4] “Silicon Sacrificial Dry Layer Etching (SSLDE) for Free Standing RF MEMS architectures” S. Federico,

C. Hilbert, et al., 2004, http://cmi.epfl.ch/etch/MEMS03.pdf

[5] Maricopa Advanced Technology Education Center (2001) Module 47 “The Etch Process”

[6] Elliot, D. Integrated Circuit Fabrication Technology, McGraw-Hill, New York, 1996 p.282

[7] Bhattacharaya, R. and Reis, A(2004) “Deep Reactive Ion Etching”, University of Maryland,

http://www.ece.umd.edu/courses/enee416.S2004/presentation6.pdf

[8] Van Zant, P. (2004) Microchip Fabrication (4th

Edition) McGraw-Hill, New York](https://image.slidesharecdn.com/pptfornano-160304012546/85/wet-etching-15-320.jpg)