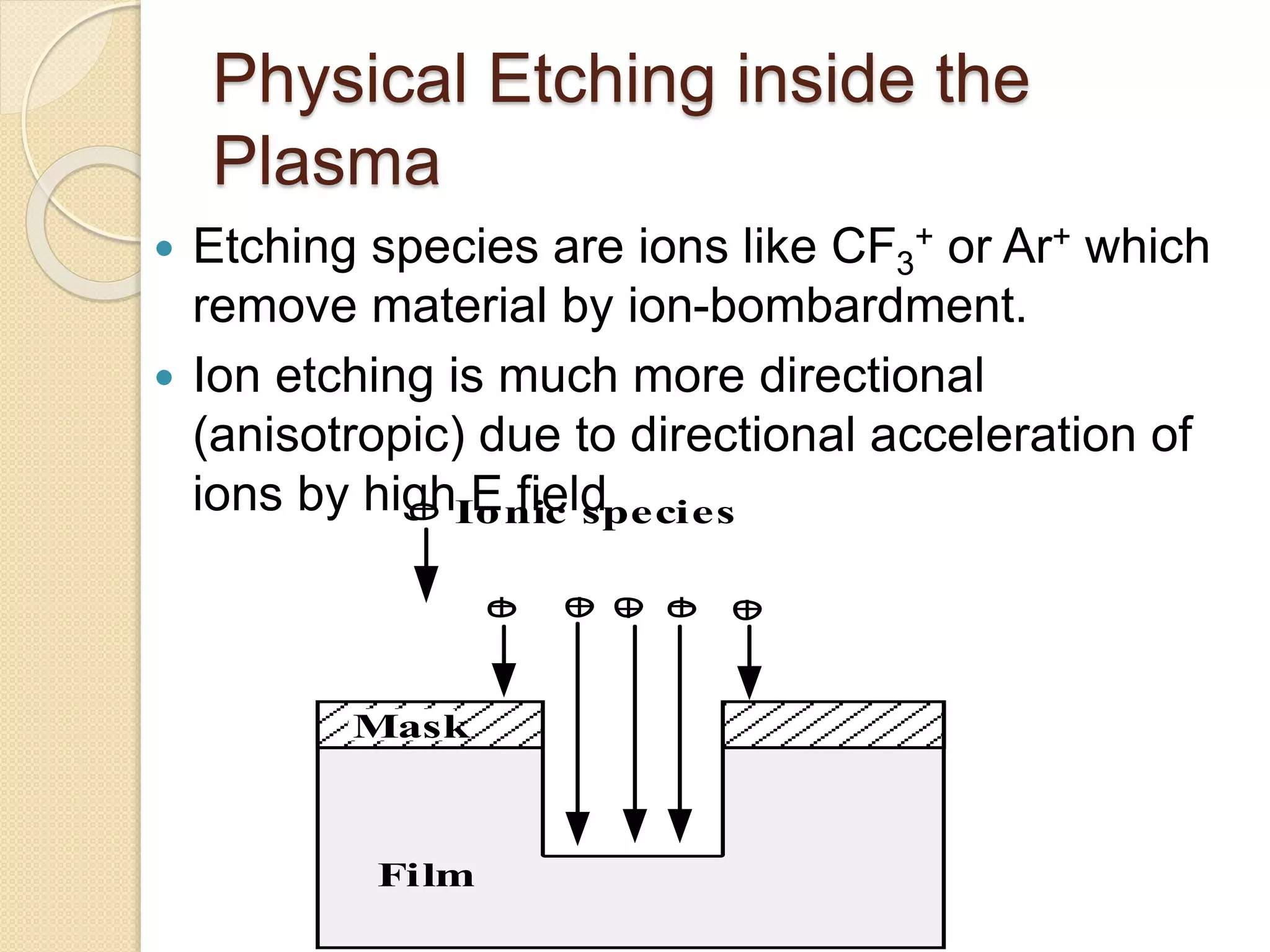

Etching is used in IC fabrication to remove unwanted materials and leave a required pattern. There are two main types: wet etching uses liquid chemicals, while plasma etching uses ion bombardment in a plasma. Plasma etching is faster, easier, and more directional than wet etching. It allows for anisotropic etching profiles with better resolution, cleanliness and process control compared to isotropic wet etching.